Do not particularly trust those who insistently repeat that it is easy to install a warm floor. The warm floor represents a complex system, the correctness of the installation is justified by a number of reasons. The basic elements of the system, used for finishing the laminate, are best suited for a "dry" type of installation. To properly implement the installation, it does not hurt to listen to the helpful advice of the home Master.

Content

Hot offer - underfloor heating

Before installing the underfloor heating, it is necessary to perform the preparatory work for leveling the surface. The work is not so complicated, floor pouring you can do. The next step is to choose the type of floor heating.

To date, the most popular option for creating a comfortable stay in the house is the electric heating system "Warm Floor".

This heating method is more efficient than radiator heating and is an alternative to an autonomous heating system. The installation scheme and methods for laying the underfloor heating allow the installation of heating for linoleum, tile and laminate.

The main obvious advantages of a warm floor hot line are: the efficiency of the system with a uniform heat distribution, no dust, accessibility of installation and electrical connection for carrying out by hand. And to buy a system of a warm floor under a laminate is not a problem. What kind of systems do manufacturers propose, and what kind of floor to choose for a laminate?

Electric underfloor heating circuits

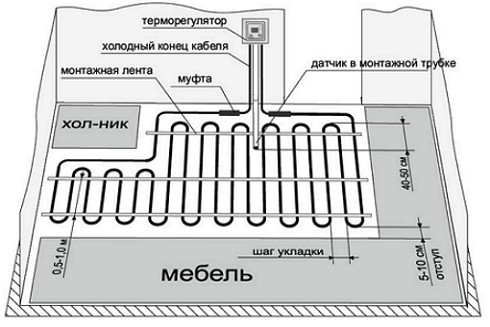

Any system of the "Warm Floor" model consists of electrical circuits. Therefore, when creating and designing a system at home or in an apartment, it is necessary to design a layout. Recall that the warm floor is not recommended to be laid in the area for subsequent placement of furniture.

The contours of the system, for example the warm water floor, should be placed indented from the walls up to 20 cm. The recommended step between the electric circuits in the wall area is 10 cm, and closer to the center of the room up to 15 cm. The scheme for laying pipes or conduit wires can be executed in the form of " spiral "or" snake ".

Helpful Tips

At external corner walls, the pitch of the pipes of the contour is made smaller or the contour is drawn directly near the wall. Each separate circuit is preferable to collect from one pipe, eliminating welding, or wires. The length of the contour should not reach 80-90 m.

Types of the "warm floor" system

Recall that there are such systems of "warm floor":

• Water floor

• electrical cable

• Film infrared.

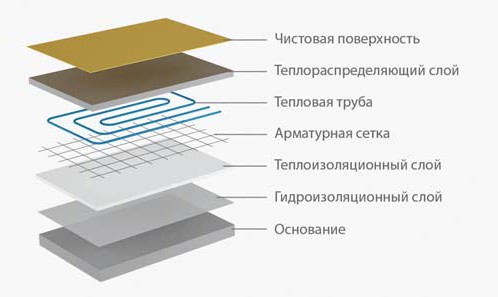

laminate and warm water system

A water-heated floor is the safest way to heat, with a uniform warming of the floor. Laying the floor system under the laminate using this system is carried out in the following sequence:

• preparation of the base of the floor

• installation of the substrate on the screed

• installation of damper tape

• laying of waterproofing and installation mesh

• stacking of water system elements

• laying a layer of soundproof material

• connection to the collector

• crimping system

• Finish with laminate.

Helpful Tips

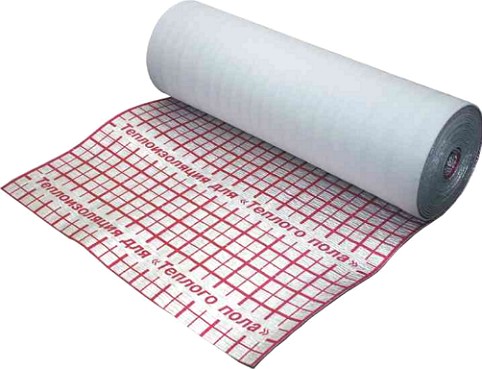

When laying the substrate on the screed, it is better to give the substrate with the marking. Thanks to the applied marking, the visualization of the placement of the contours of the system is literally in real time, which allows for quick and correct laying.

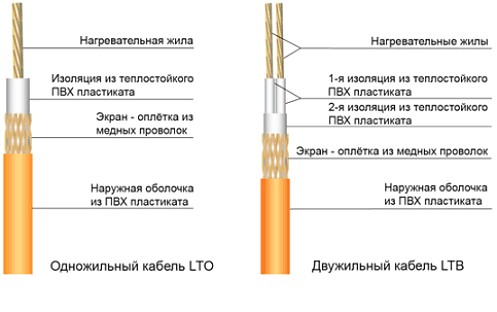

electrical cable floor system

The main element of the heating system is a cable that converts electrical energy into thermal energy. The system uses two-core, rarely single-core cables, with the distribution of the functions of the veins: the supply vein and the heating wire.

Laying and installation of a warm floor under a laminate, using an electric cable, carry out on such stages:

• prepare the base

• erect a thin screed to 0.3 cm and reinforce it with a mesh

• lay a heater with a foil layer outside

• laying and connecting cables in a concrete screed

• Mount and produce a floor finish with a laminate.

The systems of water and cable "Warm floor" are labor-intensive and expensive. In addition, the systems are terribly expensive, the cost of electric underfloor heating is beyond the power of many and the electricity consumption for heating the floor is high.

A healthy alternative is the infrared film floor, which, although it exceeds the cost of water and cable systems, but quickly pays off, taking into account the increase in energy prices, for 3 years.

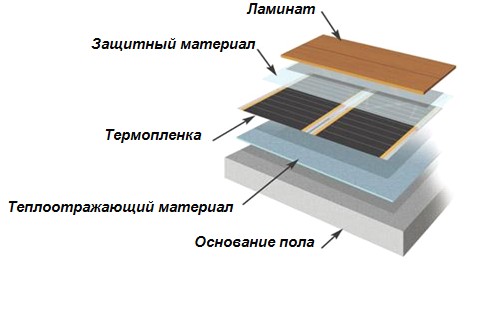

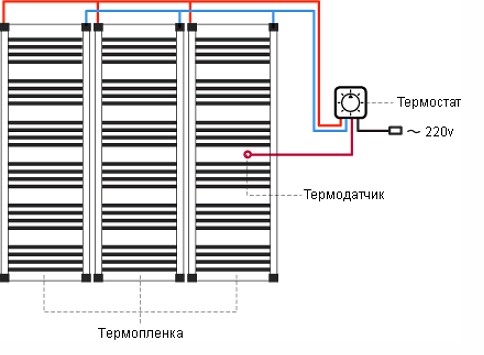

scheme of infrared film floor - we collect ourselves

The film floor system is a kind of electric warm. The infrared film floor is initially set to minimum power consumption. This is evidenced by the presence of a thermostat with a power of 3.5 kW (16 A).

It is attractive that in the event of any mechanical damage, the entire system does not go out of order, because the film floor and its contours are sections or stripes. The film, being in the bowels of the warm floor is not subject to the effects of fracture or corrosion. A ready-made set of the electric film infrared field allows to perform the installation according to the scheme for 2 or 3 hours. And most remarkable, the necessity of the screed device is completely absent.

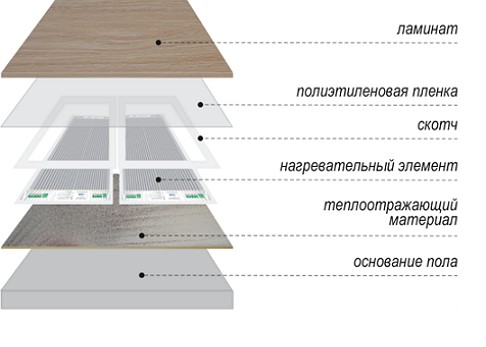

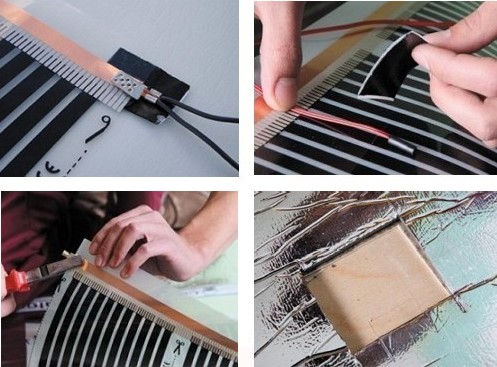

The process of laying the electric underfloor under the laminate will consist of the following:

• Preparing the floor for laying

• laying waterproofing film or reflective material

• laying film sections or strips according to the scheme

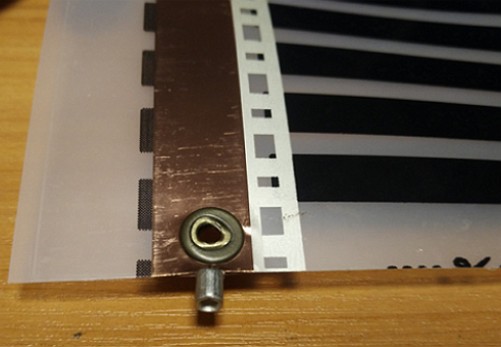

• connection and insulation of contacts of sections (bitumen insulation of copper bus bars of film strips)

• laying of installation wires to provide connections: "network-thermostat", "thermoregulator-thermo-film" and sections of thermo-film with each other

• installation of the installation box, thermostat and the floor temperature sensor

• testing and testing the system's performance, testing the quality of insulation

• stacking of polyethylene film

• We produce the finishing coat.

Helpful Tips

Buying a system of film floor, it will be necessary to buy:

• electric copper conductor of min. 1,5 mm.

• polyethylene film for waterproofing

• adhesive tape on a bitumen base 15 cm wide

• Mounting kit "Crab"

• connecting clips

• contactors.

More detailed information on the relatively self-laying of the film floor is presented in the video.