For what purposes seals are needed, practically everyone knows. Where it blows, you need to compact it, i.e. to exclude draft, keep warm. Consider the characteristics and properties of different seals. And you choose, you need silicone sealant or rubber.

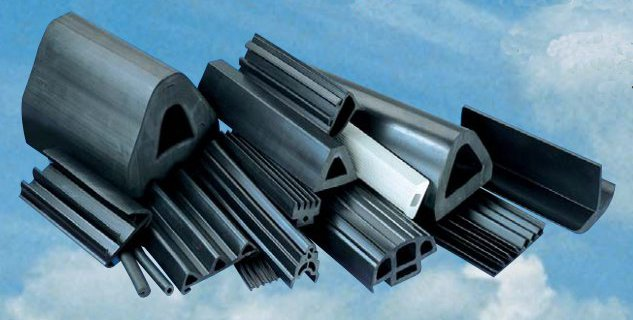

Rubber Seals

Since the school day, everyone knows that vulcanization of rubber produces rubber. rubber seals have long been widely used.

Rubber seals are usually black, black color is obtained due to the use of soot in the form of filler in the production of rubber.

Soot gives the rubber strength and therefore the most durable seals of rubber black.

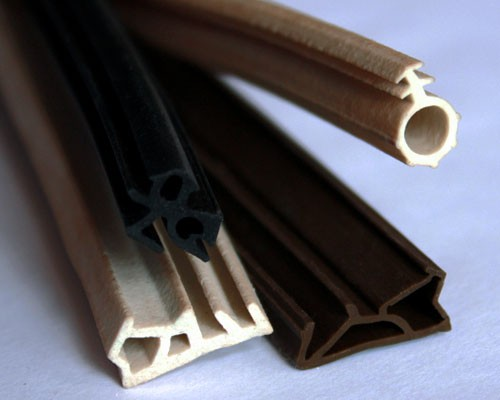

Modern manufacturers, in the production of rubber use active silicates, which made it possible to obtain strong rubber of different colors almost equal in strength and hardness to black rubber.

But because of silicate fillers, with long-term compression, the ability to return the form of the sealant to its original state has decreased.

It can be concluded that the quality of rubber seals directly depend on the quality of raw materials and the quality of additives.

At present, rubber seals are losing ground, silicone seals have moved them.

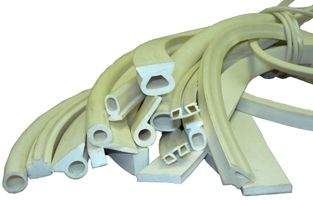

Silicone gaskets

Sealants made of silicone rubber or silicone sealants have proven themselves, as they can work at temperatures from -50 * С to + 250 * С (for example, a sealant made of silicone rubber manufactured by Rehau).

Due to their excellent properties, silicone rubber seals have become very popular in electrical engineering, medicine, food and textile industries and in many other branches of the national economy and industrial equipment.

Widely used in aircraft construction, shipbuilding, mechanical engineering.

Since silicone does not depend on temperature, it can be used at very high and very low temperatures.

In this case, the silicone sealant is able to keep the shape, remain elastic, elastic, strong, rigid and retains the ultimate elongation.

It is necessary to note the electrical characteristics, the ability to preserve the breakdown strength, the dielectric constant and the volume resistance are preserved.

At room temperature, the silicone sealant has excellent insulating properties.

What is the advantage of silicone sealants

Since the insulating properties of the silicone sealant depend little on temperature, such a sealant, in terms of its insulating performance, outperforms all traditional elastomers.

Even with prolonged storage in water, the electrical properties of such a sealant vary very little.

When exposed to fire, when the insulation of silicone rubber burns, there is still a high protection of electrical appliances and installations during overloads, as there is no conductive layer after the combustion of the silicone.

If silicone sealants are processed by all the rules - they are not toxic.

This indicator makes it possible to use silicone sealants in medical technology and the food industry.

Unlike rubber seals made from natural rubber, silicone rubber seals do not change their properties from exposure to light and air at normal temperature.

Atmospheric precipitation in the form of rain, snow, as well as sea water can not spoil the seals of silicone rubber.

Conclusion - silicone sealants are resistant to weathering.

In the electrical industry, silicone seals have been used because of resistance to ozone, to the electric corona and arc.

Modern companies produce various types of silicone sealants, the silicone profile is produced for the equipment of continuous vulcanization.

Companies can produce any ordered profile, as well as silicone self-adhesive seals and O-rings.