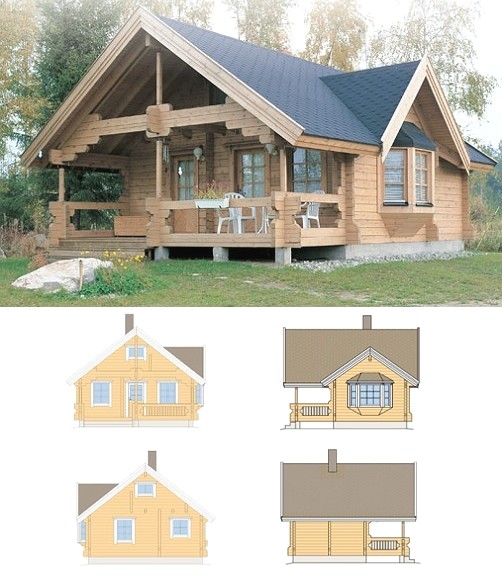

Classical or extravagant designs of houses from a bar attract those who aspire to self-expression through the arranged habitation. Glued beams are not just favorites of the season. This is a worthy champion among natural materials, combining useful properties of wood and the reliability of a durable design. Do not argue, to build a house by the rules is difficult and time-consuming. But how comfortable it is to live in such a house!

Content

Glued beams - COOL WOOD of our century

The remarkable properties of glued wood have been known for a long time, so the appearance on the market of sawn timber, glued from several bars, meant a new era of using wood.

Judging by the reviews, the glued beam does not have those significant drawbacks inherent in a regular beam or solid logs. This is a shrinkage of wood - the shrinkage of the house from glued beams less than 1%, which virtually eliminates the time for the draft of the wooden frame. Such an amazing result is achieved by improving the technology of production of timber.

Today, to build a house from glued beams means to erect an ecologically sound and durable structure. And if you trust project house DDM-Story, and they not only create projects, but also produce a quality glued beam - in the end get a wonderful house. Naturally, in order to correspond to the COOL WOOD rating, the beam has to meet high requirements of consumer standards. Fit into the standards of DSTU 2.6-151: 2010 and quality certificates in the sawn timber market is difficult. What is the reason for success and popular recognition?

Construction of houses from a timber: we select wood

When building a beam, a material is required that ensures stable geometric parameters. It is desirable that the material does not have pronounced defects in wood: cracks, curvatures, knots and porosity. Of course, I want wood to be less prone to decay and the release of resinous vysokol.

The glued timber bar has no such drawbacks. Moreover, this sawn timber without additional wood processing has good fire resistance (above grade 2). Bearing load of beams and rafters from glued beams is solid, which makes it possible to create and erect beams for large spans.

Recall that the recommended standard size of the section is best suited for erection:

• small bath or country house - 100x100 mm

• houses of medium size - 150х150 mm

• Large house or cottage - 200x200 mm.

Correctly selected profile of the beam ensures the uniformity of the load of the beam of a large section, which facilitates the assembly of the house from the glued beam.

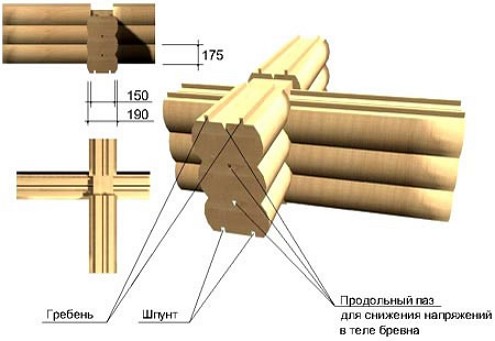

laminated timber profile secret

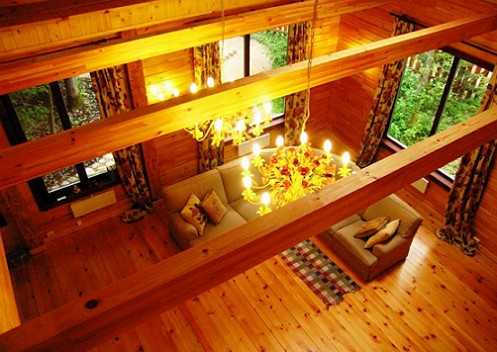

In the finished houses of glued beams, the walls look like a monolithic surface that does not require any additional finishing. The thermal insulation properties of the walls can be compared with brick masonry thickness of 60 cm, so the need for a heater simply disappears.

The profile of the sawn timber can be as follows:

• D-shaped

• Rectangular

• Round.

Modern glued beam has a smooth furniture surface. The configuration of the bar is as follows: on top is a trapezoidal crest, from below - a mirror-shaped groove in the form. The groove and the ridge fix in the wall the timber rigidly with respect to the neighboring bars, higher and lower.

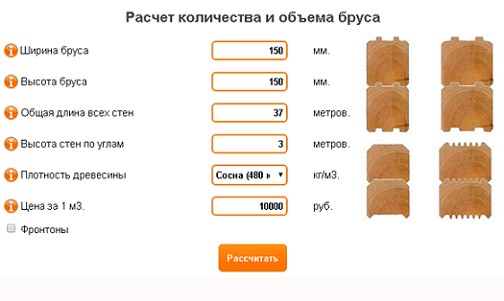

Before you can buy the laminated timber, you need to calculate the necessary materials for the finished house.

calculation of materials

Calculation of laminated veneer lumber on line is designed to determine the necessary volume and quantity of sawn timber, as well as crowns, interliner insulation, nagels and the cost of antifungal impregnation.

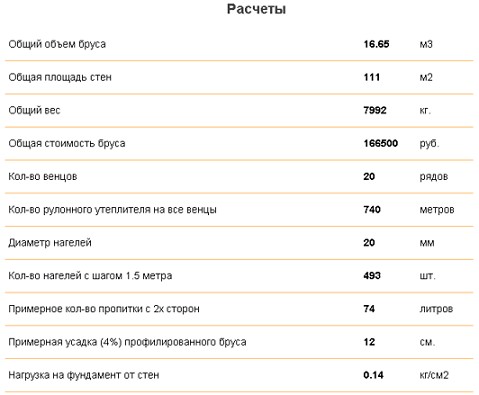

As a result of the calculation, the following data will be received:

• volume of timber and estimated number of sawn timber (m3)

• External wall area (m2)

• weight of the glued log without insulation (kg)

• number of beams of the bar in the wall according to the height of the walls and the size of the material used (rows)

• volume of insulation for all rims (m)

• number and diameter of nagels set in 1.5 m increments

• bulk amount of double-sided impregnation (l)

• approximate percent shrinkage in a year with an initial humidity of 20%

• load on the foundation without taking into account the weight of the slabs and the roof (kg / cm2).

Based on the data obtained, you can assess the readiness for the assembly of the finished house.

How to build a house from glued beams with your own hands

The assembly of the house consists of the following stages of erection:

• selection of a suitable project based on location

• calculation and erection of the foundation

• installation of a wooden box

• erection of the roof

• Installation of utilities

• exterior decoration.

Recall that the standard house design and subsequent assembly assumes the following:

• pile and belt foundation

• the wooden part of the box from the profiled beam of glued concrete section (160x160 mm), the rafter system and the overlapping, the logs and the rough floor

• roof, for example from metal roofing or other roofing material with recalculation

• Electric wiring

• Finish finishing from the lining and floor boards

• grinding, painting and flame retardant protection

• installation of windows and doors.

foundation erection

Houses made of glued timber are much lighter than brick, so there is no need to build a strong foundation. It will be sufficient to erect a monolithic, pile or strip foundation with a depth of up to 0.8 m.

For example, to build a house with an area of 100 square meters. m is required belt monolithic reinforced foundation dimensions: depth - 1.2 m, a thickness of 0.5 m and 0.4 m with lifting macadam and sand bag, with vertical and horizontal waterproofing.

According to the calculations, a reinforced 150 mm thick plate, 12 mm reinforcement and M-200 concrete will be required for erection.

erecting a box at home

For the erection of a box, houses use a profiled glued beam of the chosen profile and class, for example a three-leaved board of premium class 200х180 mm (dry). If you build a finished house out of a bar, then the manufacturer chop the cups of the house.

You will only need to gently collect the crown behind the crown and make a harness along the inner and outer walls with the installation of the mortgage board.

After the erection of the box, the houses begin to install the rafter system, the floor and the rough floor.

installation of roof truss system and roof erection

After the installation of the roof truss system (rafter, beams, lining and lathing), antiseptic all wooden surfaces with a biosecurity solution. Then proceed to roofing works, including the installation of insulation, steam and waterproofing, and, if necessary, inter-storey parobarrier.

For the construction of the roof of the house from the timber, it is possible to use bitumen shingles, metal tiles. Heat insulation is recommended to be made using ROCKWOOL 200W mineral wool. At this stage, eaves are sewn, a plastic or metal gutter system is installed and snow holders are installed.

But the process of assembling the house does not end there. Ahead the device of a rough floor, an internal furnish, grinding and painting, the installation of doors and windows.

More information about the process of assembly is presented in the video.