The choice of floor covering is not easy, given the variety of modern materials. But, some of them remain popular for many years. For example, linoleum. It is simple in laying and universal, suitable for all premises. About what kinds of this material exist and how to pack it independently in this article.

Content

Types of linoleum

Linoleum is the most versatile material for flooring.

Like other materials, it is divided into species according to the following parameters:

- material of manufacture;

- strength and scope of application;

- structure of the coating.

Let's consider in more detail all kinds of material. Depending on the composition of linoleum can be:

- Natural - consists of wood tar, cork flour, lime and linseed oil. It was from him and the name went linoleum. This is an environmentally friendly coating, resistant to inflammation. It can be made even in the kitchen, tk. it does not absorb fluids.

- PVC Linoleum - can be produced on a fabric, foamed basis or on a layer of heat-insulating material. Can consist of one or more layers. Its main drawback is the presence of a smell, which is long eroded.

- Rubber or reel - consists of two layers. The basis is a layer of crushed rubber, the upper part is made of artificial rubber. Coloring can be varied. This species has a high wear resistance.

- Linoleum of nitrocellulose - has a beautiful shine and is resistant to moisture. It is made without a base and can easily light up.

- Alkyd - is fabricated on a fabric basis using alkyd resins. It has high heat and sound insulation properties. But more fragile than other analogues.

Depending on strength and application, the material can be divided into:

- Domestic - is used in residential premises, has a thickness of 4 mm. A rich choice of colors will please any buyer. This kind is very soft and easy to assemble, the only one can be pressed under the furniture over time.

- Semi-commercial - most often applied in the form of flooring in offices and hotel rooms. From the previous it is distinguished by the presence of a protective layer with a thickness of 0.7 mm, which increases the service life.

- Commercial - used in rooms with large cross-country, for example, the store's shop floor. It is very durable and has a polyvinyl chloride compound.

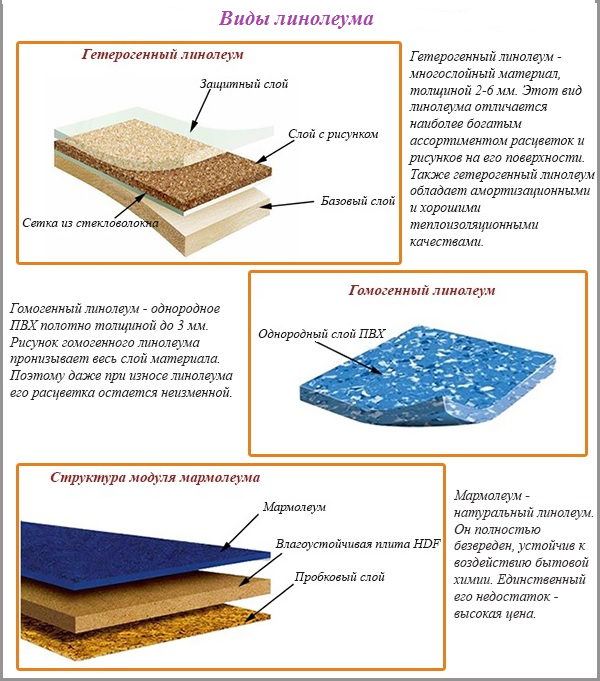

By its structure, linoleum is divided into:

- Homogeneous - PVC granules and dye are evenly distributed throughout the material. The figure is not obtained on the surface, but over the entire thickness of the material. This makes it more resistant to erasure.

- Heterogeneous - consists of several layers, the number of which can reach six. The basis for it is a woven fabric or foam base. For strength in the structure of this material is fiberglass.

- Without a basis - a rather thin material up to 3 mm. Cheap, but not durable.

- With the base - this linoleum can be on a heat-insulating or fabric basis. It falls well on any surface.

When choosing a material, be sure to pay attention to its characteristics. For the house is perfect for household or semi commercial linoleum. You can give preference to the second kind, because he is more reliable.

Laying linoleum with your own hands (step by step)

Linoleum is the most democratic floor covering. But when you install it, you need to foresee a lot. At the very beginning of the work, it is necessary to level the floor, whether it is concrete or wooden. We repair all the cracks and irregularities. After this, it is necessary to calculate and select the material itself. Basically, they try to put a cover without stitches. To do this, you must select a model for the width of the room. For example, you want to lay a cover in a room 4 m wide, respectively, choose a linoleum of the same width. After that it is necessary to prepare consumables (glue, nails, double-sided scotch tape). And tools (a knife, a tape measure, a notched trowel, a hammer). Now you can proceed to the installation of the coating.

linoleum on the wooden floor

Laying the material on a wooden floor is as follows:

Preparation. If it is painted on it, you need to remove it with a construction hair dryer and a trowel. Then it is necessary to level the surface with a grinding machine. Thus we will remove large irregularities. Further preparatory work can be done in two ways:

- shpaklevan joints and gaps between the boards;

- flooring with plywood or chipboard.

The first option is rather laborious and takes a lot of time. The second method is most suitable and gives a uniform surface. This is great for linoleum. In addition, no waterproofing is required, because the tree should be ventilated. If desired, you can put a layer of sound insulation made of foam polyethylene. And between the sheets of plywood, you need to leave a gap of about 1 mm, so that the floor does not creak.

Calculation of the amount of material. This is a very important stage. It is necessary to measure the width and length of the room taking into account all niches. The material is better to buy with a margin, because perfectly flat walls do not exist. If the width of the room is not too large, you can buy one piece of linoleum, which will lie well throughout the floor of the room. If you can not get by with one piece, buy two. And one of them should have a margin along the length and width (especially if the material with a picture). This will fit two parts perfectly to each other. The joint must be made in the center of the room. After all the measurements you can go for linoleum.

Cutting material. To do this, it is necessary to spread the material on the floor in the room and give it a little time to lie down. After this, cut off the excess with a knife, starting with large fragments. Do not try to cut everything off at once. It is better to leave a small stock. After that, on the inside of the material, make a marking and trim the remaining excess with scissors. So the edges will be smooth, and the material will lie perfectly.

Linoleum laying can occur on a special adhesive, which is applied to the surface of the floor with a notched trowel. You can also use double-sided tape. It is best to fasten the joints of two sheets of material. When laying on the adhesive, the material is carefully laid on the treated surface and rolled out with a roller to remove air from under the material.

The final stage consists in the installation of skirting around the perimeter of the room and the installation of padding. The plinth must be fastened to the wall. Screws are screwed by screws on the edge of the material entering the doorway.

That's all, the work on installing flooring can be considered successfully completed.

linoleum on concrete floor

As in the previous case, all the work can be divided into stages:

- Floor preparation. The surface must be leveled from the differences and unevennesses. It is best for these purposes to use the self-leveling mixture.

- Material selection. For a concrete floor, models with a heat-insulating layer are best suited. So the floor will be warm.

- We lay a layer of waterproofing. For him, an ordinary film with a thickness of 200 microns is suitable. Lay it must overlap, with the approach to the walls about 5 cm.

- Installation of the coating. On the resulting surface we lay linoleum and cut the excess. After that, in addition, fix it with skirting boards. That's it. A warm and reliable floor is available.

Linoleum liner

The substrate is an insulating material.

It is necessary for:

- smoothing the floor surface;

- soundproofing;

- thermal insulation.

Depending on the material of manufacture, it happens:

- Jute - in its basis vegetable components. Also in it there are fire retardants, preventing burning and rotting. It has the ability to absorb and remove moisture, without getting wet.

- Cork - is made from crushed bark of a tree. It has excellent indicators of heat and sound insulation.

- Linen - is made of natural materials and provides good ventilation between the floor and linoleum.

- Foamed substrate - is made of expanded polyethylene. Such material quickly becomes overwhelmed and loses its properties.

The choice of the substrate depends on the coating on which the material is laid. And it is chosen based on its properties.

linoleum underlay for concrete flooring

The concrete floor is quite cold, and even laying linoleum, walking on it will not be comfortable. In this case, it is necessary to use a substrate, which will play the role of additional thermal insulation. The cork substrate has the best results. It is environmentally friendly material that is safe for human health. The average price per square meter of cork is 120 rubles. Also a perfect combination material. It consists of a mixture of wool, jute and linen fibers. Also has good thermal insulation properties. A distinctive feature of this type of material is high density. The price of the material is quite affordable and varies from 30 to 60 rubles per square meter. m. By this floor it will be possible to walk calmly even in winter.

linoleum underlay on the wooden floor

The wood has good thermal conductivity and soundproofing properties. Therefore, in additional insulation does not need. The only drawback of such sexes is unevenness and creak. To eliminate these defects, it is best to choose jute or linen substrates. These materials are natural and safe for human health. As a result, you get a smooth and warm floor without any extraneous sounds. Substrate of jute costs an average of 40 - 60 rubles per square meter. m, and linen 50 - 80 rubles per square meter. What kind of choice do you decide. By their characteristics they are the same.

This article tells about linoleum. Its types and examples of laying on various coatings are given. Also tells about the types of substrates and their cost. Using the advice of the article, you can easily select the material based on the operating conditions, and lay it in your home. Successful work.