To insulate the walls and ceilings of structures often use mineral wool. The name is somewhat generalized, with wadded material means three different materials made from basalt, glass scrap or slag. Naturally, each type of cotton has its own characteristics. The unifying moment is the structure of the material, which is a fiber of different dimensions, the arrangement of the fibers can be directed or chaotic.

Content

Varieties of mineral wool

From what has been said above it is clear that according to the material of the mineral wool production, it is divided into three types. Glass wool, basalt and slag fibers have approximately the same heat-saving characteristics, they are quite high and are provided by the material structure itself, heat retention occurs due to the air cavities formed by fibers.

On sale it is possible to meet minvat in the form of mats, rolls of plates, placers. Each option has its own advantages and is used for its intended purpose.

For example:

- if it is required to exclude the possibility of formation of cold bridges, then the use of a roll material,

- with the help of mineral wool plates it is possible to create a system of vertical insulation, during the operation of the plate I will not creep or be deformed,

- the field of use of a blowing material - frame construction, modern technologies allow filling even hard-to-reach parts of frame partitions with loose cotton wool,

- to obtain the maximum effect, it is recommended to use a foil material,

- if the aim is to simplify installation as much as possible, reinforced materials are used.

The technology of mineral wool insulation involves the use of materials that in terms of thickness and density corresponded to the temperature characteristics of the climatic zone in which the insulated buildings are located.

Advantages and disadvantages of mineral wool

Before you decide on a mineral wool insulation, you should carefully study its qualities.

As positive factors note:

- not flammability,

- absence of impurities in concentrations dangerous to humans,

- the possibility of use for external and internal insulation,

- the possibility of warming wooden structures, the structure of mineral wool allows creating a breathable layer that protects wood from accumulation of moisture and the appearance of putrefactive processes,

- durability, manufacturers claim that this type of insulation can be successfully used for 70 years, without replacement,

- the correct installation of mineral wool slabs will allow to maintain the heat quality for the whole lifetime.

To give the plates the desired shape, you can use a conventional sharp knife, the installation of fragments is quick and easy.

The main drawback, which experts usually indicate is the hygroscopicity of the material, cotton wool tends to absorb moisture, the raw material loses its heat-saving properties, with a moisture content of cotton wool of only 2%, resulting in a 10% reduction in its thermal insulation characteristics.

To avoid negative phenomena of this kind, one should adhere to certain rules and installation schemes, in heat-insulating systems, in the arrangement of which the mineral wool is used, ventilation gaps, steam and waterproofing should be provided.

On the advantages of mineral wool - watch the video:

Warming of walls with mineral wool - how to choose a material

Tip number one - you should not save, you should purchase an exclusively certified product, preferably from well-known manufacturers such as: Rockwool, Knauf, ISOVER, URSA, Beltep, PAROC, IZOVOL. The products of these companies are thoroughly tested before they enter the building materials market.

Please note that the price of wool is directly dependent on its density, and density, in turn, guarantees higher quality characteristics.

If you make a choice, then between stone and basalt cotton. More cheap glass wool and slag wool have more disadvantages, they are characterized by lower noise insulation, in addition, glass wool is a material that requires special care during installation. Its fibers, getting on the skin of a person cause a strong irritation, and stuck in the skin fragments for a long time will cause redness and itching.

Also, when selecting, note that:

- material with chaotically located fibers is able to withstand sufficiently high loads,

- vertically arranged fibers contribute to the increase of thermal insulation and sound insulation characteristics,

- from the purchase of material with horizontally oriented fibers it is better to refuse, although such an option is extremely rare.

When buying material, you should study the composition of cotton wool, it is always indicated on the packaging label.

Provide the most qualitative thermal insulation of the walls can be a mineral wool heater, the thickness of mineral wool should be calculated correctly.

Before proceeding with the installation work, you will need to study the safety recommendations

Although there are quite heated discussions about how dust is harmless. exuded by mineral wool materials, but it is best to be safe. In fact, contact with the material and dust should be reduced to a minimum.

To exclude the possibility of contamination of premises with dust and fragments of fibers, it is necessary to build a fencing made of gypsum board, plywood or polyethylene film.

In the work area there should be no drafts. The working person should wear overalls, glasses, protect his hands.

Upon completion of work will require thorough cleaning of the premises. After cleaning, change clothes.

Such precautions can cause negative emotions in those who are going to perform wall warming with mineral wool. Note, this is basically wrong. In everyday life, we use many dangerous inventions of civilization, for example, electrical appliances, because electric current is deadly to humans.

But none of us will not give up this good, because the danger can be eliminated by observing the elementary rules of behavior. Similarly, with mineral wool materials - compliance with safety rules and the use of personal protective equipment will avoid unpleasant phenomena.

The installed material, as a rule, is reliably isolated from household or residential premises by layers of finishing materials.

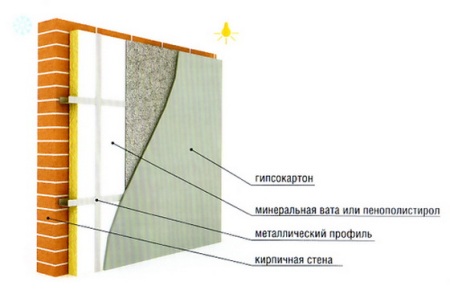

Warming of the wall from inside with mineral wool - mounting options

For the insulation of the walls of the room, three installation options can be used:

- on the frame of wood or metal profile

- with the use of mounting brackets

- using a plinth cornice

We have already mentioned that the quality characteristics of mineral wool can deteriorate sharply if the moisture content of the material rises. Those. the process of insulation must necessarily provide for the arrangement of the vapor barrier layer.

Layout of layers on the insulated wall should be as follows:

- between the inner finish of the wall and the vapor barrier membrane should be a small air gap,

- a layer of insulation is laid on the membrane,

- the whole structure is sewed with plasterboard.

Working tools will need the most common:

- hammer, level and roulette,

- knife and saw blade,

- marker and mounting tape,

- a stapler and a screwdriver,

- fasteners: self-tapping screws, nails and dowels,

- marker.

how to prepare the walls

To bring the walls to an ideal smoothness is not required, during the installation of insulation and finishing, all minor unevenness will disappear.

But it will be required:

- eliminate significant protrusions on the walls,

- remove fragile fragments of plaster,

- treat the walls with antifungal agents.

features of installation with the use of a wooden and metal frame

Before starting work, determine which kind of crate is more acceptable in your conditions: wood rails or metal profiles.

disadvantages of wood and metal profiles

It should be borne in mind that the installation of a metal structure will require processing it with anti-corrosion agents. Wood in the process of operation can give shrinkage, with significant changes in humidity and temperature, deformation of the material can occur. In addition, wood will also require treatment with antiseptic impregnations.

installation of metal profile

Mounting of the laths from the metal profile is carried out in the following sequence:

the frame assembly should be performed at a distance of about 10 cm from the wall,

profiles should be fixed vertically, step - from 60 to 100 cm,

The parameters of the battens must correspond to the parameters of the insulation.

vapor barrier

Next, you can proceed to install a vapor barrier layer, the best option is a foil film.

Install it with a shiny side inside the room. Fixing strips is carried out in a lap. To strengthen the effect of the joints, it is recommended to glue with a metallized tape.

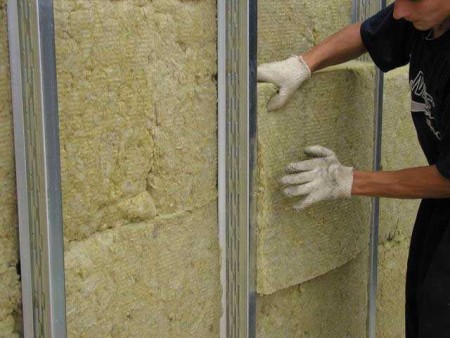

montage of mineral wool

The process of laying cotton wool is quite simple, is as follows:

- the laying of cotton wool is carried out between the skeletons of the frame,

- the frame is sewed with plasterboard,

- apply the finishing filler,

- perform finishing work.

Decorative and finishing materials with this type of installation can be used any.

Let's see a video about how the wall is insulated from the inside:

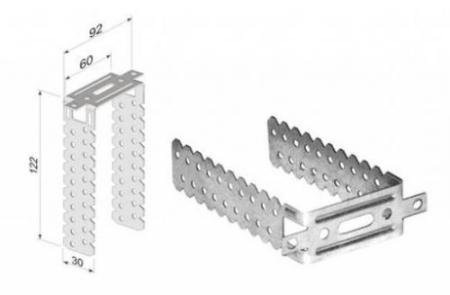

How to install using staples

Technology using staples has the following features:

- on the wall brackets are installed to fix the profiles,

- have staples in vertical rows, in steps of 50 to 60 cm,

- the attached brackets are attached to the--shape.

Such fastening will allow reliable mounting of both minvate sheets and profiles.

Next, the minvate is unpacked, pieces of the required length are cut off, the stock should be about 10 cm. It is not recommended to refuse the stock, even a slight deformation of the material will lead to the fact that the length of the strip is not enough to completely cover the entire height of the wall.

Cut off and tried on the stripes on the set braces. The next strip should be worn so that there is a small accordion.

The pieces of mineral wool are easily pierced with staples, the vertical sheets are easy to install wadded sheets, since the sheets are cut off with a stock, they will cover the wall completely, without ruptures.

Next, you must install the profiles, fixing them on the mounting brackets. The film-hydro-barrier is fastened in this case by means of self-tapping screws. The film is installed in the case if a mineral wool without foil is used.

The prepared profiles are fastened with plasterboard, the joint lines are shpakuyutsya.

Warming of walls with mineral wool outside

This task is more complicated than wall insulation from the inside, nevertheless, if desired, you can cope with it on your own, the main thing is to adhere to the technology of performing works and use high-quality materials.

Among the advantages of outdoor insulation are usually indicated:

- the possibility of organizing the protection of the facade from the negative influence of the environment, protecting the house from frost and heat, wind and ultraviolet rays,

- the usable area of the premises remains unchanged,

- as a result of work on the insulation and installation of new finishes the house acquires a more attractive appearance,

- the dew point moves outward, i. e. The walls will be insured against the appearance of raw spots and the development of mold.

Warming of the facade can be made in different ways:

- by arrangement of a hinged facade

- creation of a "wet facade"

- by way of "wells"

More on the insulation of walls with mineral wool from the outside - on video:

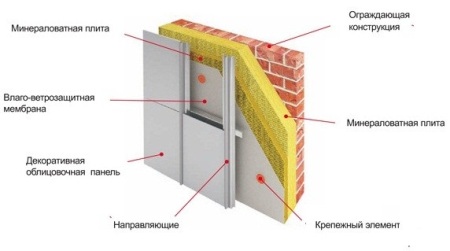

ventilated facade

It is used for insulation of concrete, brick and wooden walls or facades from a foam block. This method will require the construction of a frame structure outside the room, the space between the structure and the wall is filled with mineral wool plates, the fastening of which can be done with glue and dowels.

The facing layer is installed over the insulation. The peculiarity of such facades is the presence of an air layer, i.e. ventilability. This design allows the moisture to be removed without hindrance, while the mineral wool retains the technical characteristics over the entire service life.

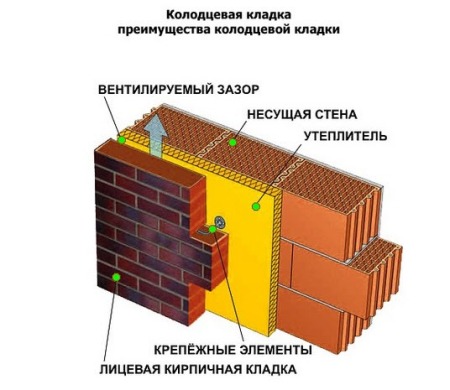

wellwork

Its application is possible if the insulation is made during the construction phase or during the reconstruction.

Mineral wool insulation must fit inside the wall.

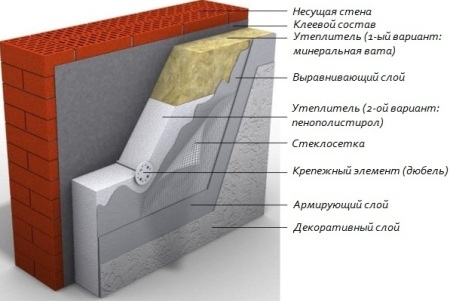

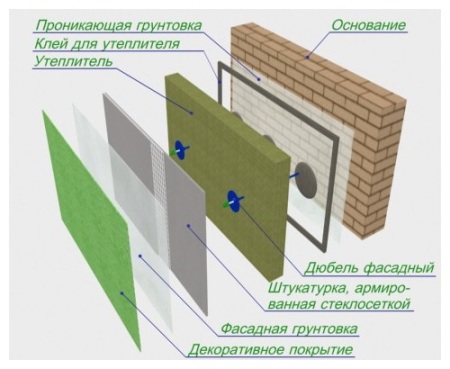

wet facade

This method involves the installation of a warming layer on the surface of the facade. As a finishing in this case, a plaster is applied over the warming layer.

The order of the work will be as follows:

- preparation of the surface of the insulated wall,

- installation of socle cornice,

- installation of a heat-insulating layer by means of dowels and glue,

- installation of reinforcing mesh,

- application of decorative plaster, if desired - subsequent painting.

warming of a brick and wooden house

For the warming of the brick house it is necessary to use plate mineral wool material, the work begins with the installation of the crate, then the mineral wool is put in its grooves.

The procedure for installing the insulation on wooden walls is as follows:

- first install a crate for a layer of heat-insulating material,

- layer of mineral wool,

- the second layer of the crate is assembled,

- the exterior is fixed.

In order to insulate wooden walls it is convenient to use mineral wool in rolls, five centimeters thick.

Experts advise to use for the construction of the flooring bridges in thickness equal to the layer of insulation material.