Linoleum - simple in laying and maintenance floor covering. Insulation under linoleum will help to make a good warm floor with minimal costs. In this article in detail it is told, what kinds of heaters exist, are given advice and recommendations how to lay linoleum and a heater by own hands.

Content

Linoleum. Characteristics and properties

There are several varieties of linoleum, the most common is synthetic PVC (polyvinyl chloride) linoleum.

In its structure it is divided into:

-

single-layer (homogeneous);

-

multilayered (heterogeneous).

On technical characteristics distinguish:

-

domestic;

-

commercial;

-

semi-commercial.

Household linoleum has a thickness of up to 4 mm, it is quite elastic and practical. A wide choice of color decors, imitating any floor covering, low cost make linoleum the most demanded floor covering in residential premises.

Commercial linoleum is used in public premises with high traffic and increased load. A durable protective layer makes it possible to achieve high wear resistance and long-term preservation of appearance. The full term of commercial linoleum is 25 years. This coating is not intended for residential premises.

Semi-commercial linoleum has averaged parameters and is used in public premises with low traffic.

By the presence of a PVC base, linoleum is divided into:

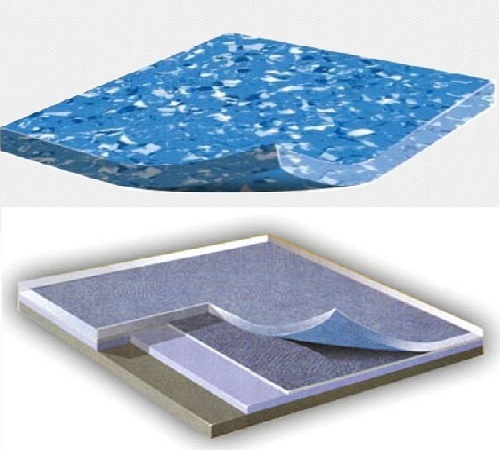

- Baseless linoleum. This material is rather thin (1.5-2 mm), is the cheapest linen, the pattern is located throughout the thickness. When laying requires a carefully prepared surface, the service life of up to 7 years.

- Linoleum on the basis. Such a web is elastic, easily laid on any prepared surface, has heat-insulating properties. Polyester, felt, jute, foamed PVC serve as a basis. The thickness of this linoleum is up to 4-5 mm.

- Among consumers, linoleum is becoming popular on a heat and sound insulating base (TZI). It has good protective and practical properties, meets all necessary standards and sanitary standards.

Than to warm a floor under linoleum

Insulation of the floor is an important stage of finishing works and repairs, this measure is extremely necessary in apartments located on the ground floors, in children's rooms, in private houses. The floor warmer for linoleum should be strong enough and springy, resistant to compression and have reduced water absorbing properties.

what insulation to put under linoleum

- Linoleum with a base. This is the easiest way to add some heat insulation to the floors. But, with a very cold floor, can not be compared with the additional laying of heaters.

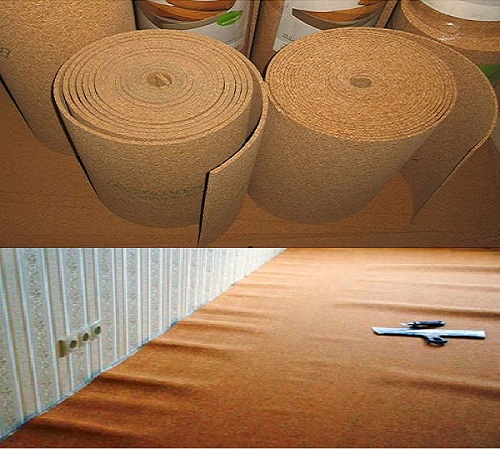

- Cork litter. A good method, which, together with the thermal insulation effect, can provide additional sound insulation. The roll plug is easy to use and elastic enough. Over time, there is a possibility that all possible bumpy irregularities will be transferred to the linoleum. Especially it will be noticeable when using a single-layer linoleum. There is also the possibility of flexing linoleum in places of constant pressure. Using a cork with the greatest rigidity will circumvent this problem.

- Sheets of fiberboard or plywood. This method will create additional heat and sound insulation and will allow to get a flat surface for linoleum in old houses. Fibreboard or plywood before laying it is necessary proolelifit to avoid swelling from possible contact with water, when it flows under the linoleum.

- Special insulation. Usually it is expanded polystyrene (foam), or EPSP - extruded (extrusion) expanded polystyrene. EPS is somewhat more expensive than foam, it is usually used in places with a high likelihood of moisture due to the leakage of water under the linoleum. A special heat effect can be achieved when using this heater on the lags.

- Natural heaters. These include jute, linen and combined substrate. Thanks to flame retardant (flame retardant) and antiseptic treatment, natural material acquires resistance to burning, mold and decay. Buy this insulation with the maximum density.

If the floors in the rooms are very cold, then for quality insulation it is best to make several intermediate layers between the concrete floor base and linoleum. Most often in the apartments on a concrete slab a heater is laid, then sheets of fiberboard or plywood in several layers, then linoleum.

How to lay the heater

Having decided to insulate the floor, you should pay attention and calculate the thickness of the insulation. Such material should even out unevenness if the floor is not perfect. Also, the thickness of the insulation should not affect the quality of laying the linoleum itself. The choice of the method of warming depends on the preferences and possibilities of the buyer. For each type of insulation under linoleum, the price depends on the composition used and the quality characteristics.

plywood is a decades-old method

The cheapest way is to insulate the floor with fiberboard or plywood. But because of the instability of the fiberboard to moisture and the laboriousness of the laying process, this method is practically not used. The method of insulation with plywood is popular in old houses because of the possibility not only to insulate the floor, but also to level it. Plywood should be cut to several sheets. They are attached to the wooden floor by screws, to the concrete - dowels.

optimal solution - cork insulation

Cork insulation is rightly considered one of the best in the ratio of price and quality. Linoleum, laid on such a material, becomes soft, pleasant, when walking, the floor springs a little. Good for a children's room. The structure of the cork allows the air to circulate freely, which creates a wonderful heat-insulating effect. This material is durable and has high levels of noise absorption, which is very important in multi-apartment buildings.

Undoubtedly, the big plus of a cork insulation is resistance to moisture and burning. A warmer from the bark of cork oak has good hypoallergenic properties.

Such a substrate is not demanding on the surface to be coated and it hides the defects of the substrate well. You should be prepared for the fact that when laying on a wooden floor under a cork insulation you will need to lay the sheets of particle board. The seams of wooden panels and cork should not coincide.

On the concrete floor, if there are a lot of defects or irregularities in it, you can also lay plywood sheets, or you will have to make a new screed. Before placing the insulation on concrete, the issue of waterproofing is solved. To do this, a polyethylene film with a overlap of 20 cm joints is spread over the entire surface, joints are sealed with moisture-resistant tape.

To the cork insulation is applied "free styling". Tapes or sheets of cork are applied tightly to each other and fastened with a construction tape.

universal expanded polystyrene

The insulation made of polystyrene foam withstands significant loads, during the long-term operation it is not subjected to deformation. Has a porous structure and a low water absorption coefficient.

Before installation, it is recommended to unpack and lay out the plates for smoothing and leveling. This method of insulation can be applied to all types of flooring and does not require additional fastening and gluing.

The plates of the heater are cut to the required dimensions, the joints are glued together with a special adhesive tape. Plywood sheets are stacked on top. Plywood creates additional rigidity of the structure.

solid insulation with expanded polystyrene

Mounting of plywood on the logs, between which the insulation made of expanded polystyrene is laid, is an effective way of warming the floor in a private house or in an apartment with high ceilings.

This design creates maximum heat and sound insulating effect. The plywood is attached to the lags by self-tapping screws. They need to be deepened somewhat to create a smooth surface. The pits of the screws and the joints must be carefully plastered and sanded.

We lay linoleum on a heater correctly

Household PVC linoleum is easy to handle, flexible, its styling is quite easy, but requires careful measurement and strict implementation of certain rules.

Linoleum is laid on a dry, even and clean surface, which was made with a heater and plywood laid on it. If you have a picture, you need a thorough docking, so it's best to buy a whole linoleum linen by the size of the room.

If the linoleum was in a cold room, then before laying it is kept in a roll in the heat for about a day. After that, the free laying and preliminary pruning of linoleum with an allowance of not less than 10 cm is made. Then cut linoleum on the ruler with a special knife with a gap between the wall of 5-7 mm. Particular care should be taken when pruning around pipes, bends and bends. In this form, the material is left for another day or two for complete spreading.

After the linoleum linen is completely smoothed, you can nail the plinth. Normally linoleum is laid without gluing. Covering, consisting of several parts, glued with a special double tape, or cold welding is used. Double-sided adhesive tape can be applied in the joints, along the walls and around the doors. In the doorway, the edge of the linoleum is cut off along the center line.

The second way is the use of glue and mastic for linoleum. Depending on the adhesive materials used and the types of linoleum, the methods of sizing the substrate and substrate are somewhat different.

Cloth linoleum should be bent to half. The glue is applied to the base of the floor, the linoleum is laid on top and carefully smoothed to level and "pasture" the air. Then the second half is glued. In case of laying several canvases, it is best if there are factory edges at the joints. The piles are lapping about 5 cm. The edges of the joints are not smeared, this must be done after cutting. At the joints under the ruler, both layers are cut, the edges are greased with glue, laid and pressed.

Insulation, used before laying linoleum on the floor, can be different in types, their practical and economic qualities. But the necessary conditions are, safety, good heat and sound insulation functions, increased fire resistance and low water permeability. Natural materials should additionally be impregnated with antiseptic compounds for resistance to fungi and mold.