Cordless screwdrivers are attracted by the ability to mobilize any construction or construction work. However, the process of battery life is limited. How to choose, charge and repair the battery?

Content

Choose the right batteries for the screwdrivers

The main nutrient for household and professional screwdrivers are accumulators. Especially for each individual battery, the manufacturer develops its own battery design suitable for brand products.

However, for an unsophisticated consumer, such a statement of the question creates inconvenience. What are these inconveniences in practice? Everything is offensive to the point: technological solutions for connecting screwdrivers and connecting terminals of the battery from the manufacturer are difficult to connect, and most importantly to fix. Adapters and wires for energy carriers of "foreign" firms do not allow to make connection and reliable fixation. Only rare "Kulibin" can conquer "iron" - battery cells (banks) for screwdrivers. How to choose the right battery for a screwdriver?

For a certain type of work, the corresponding types of accumulators are calculated, calculated for workloads. Therefore, the more significant the battery power indicator, the longer it is able to work.

Is the battery as terrible as it is painted?

Energy carriers for screwdrivers are divided depending on the composition of the active substances used. These are the following types of batteries for screwdrivers of the type:

• nickel-cadmium

• Nickel-Metal Hydride

• Lithium-ion.

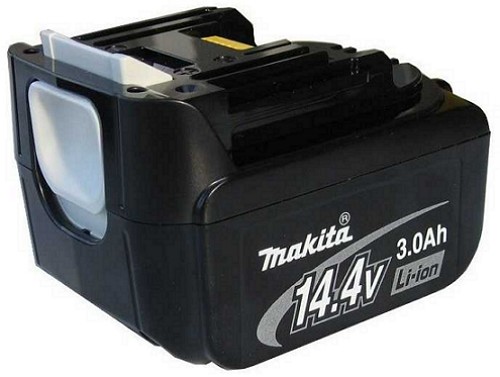

The operating ranges of the battery cells are: 9.6V; 12 V; 14.4 V; and professional screwdrivers are equipped with 36 V batteries.

Since the appearance of the first lead-acid batteries used exclusively in the automotive industry, total "accumulation" has acquired global dimensions.

Nickel-cadmium batteries, most often used in screwdrivers, are fond of cheapness and large capacity. However, problems with the toxicity of production of this type of batteries and their subsequent disposal remain an unresolved problem.

The next generation are nickel-metal hydride batteries. This combination of high-density working current and safe (in comparison with cadmium batteries) production.

The most promising were lithium-ion batteries. By the way, when choosing a battery, pay attention to the designations: Li-Ion, Ni-Cd, Ni-Mh.

For example, the inscription 2607335432 14,4V 2.4Ah Cs NiCd A49110Y will mean that you have a nickel-cadmium battery with a working power of 14.4V for 2.4 amperes per hour with 12 banks of standard size connected in series. Who does not believe, he can open the battery and make sure of yourself.

Lithium batteries for professional screwdrivers are an ideal option. Nature generously rewarded them with an electronic system, a built-in chip that unerringly remembered the amount of charge-discharge, residual capacity and intensity of battery usage.

For comfortable operation it is recommended to have two batteries in use, using one of them, while the second one can be put on recharging.

Charging and repairing the battery

In the process of intensive use of the screwdriver after a while there is a need for charging or repair, as well as replacing the batteries or purchasing new ones. In most cases, the option of repairing and charging batteries is selected. How do I charge or repair a battery with my own hands?

How to charge the battery

Charger

Chargers are used for charging screwdriver batteries. There are two types of charger devices:

• standard

• Impulse.

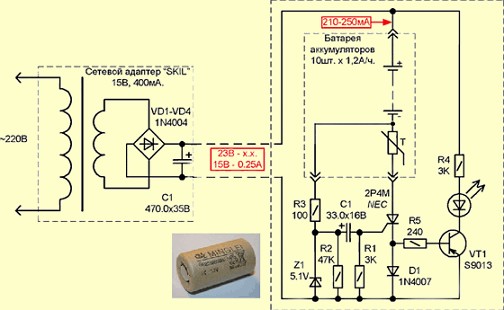

A standard charger is used to charge household screwdrivers and charges the battery in 3-6 hours. The impulse charger is more suitable for charging a professional instrument. The increased efficiency of the pulse charger allows charging in an hour.

To charge the battery, the temperature condition of the charging process is a prerequisite. This ambient temperature is above +10 degrees, but not above +40 degrees. It is noted that during any charging, the batteries are heated, so it is recommended to cool them. The charger, which is responsible for the full charge cycle, has a light indication. The light indication allows you to determine how the charging process is performed. The charger for charging the screwdriver battery carries out the process from 30 minutes to 7 hours.

For example, a nickel-cadmium battery with a capacity of 1.2 Ampere hours will be charged with a current of 250 mA for about 7 hours. In this case, the DC component of the charging current helps to support the charger's network adapter. After charging the battery, the batteries must be removed from the charger. Keep charged batteries is recommended separately from the screwdriver.

How to repair the battery

In some cases, the screwdriver battery does not charge. The reasons can be enough:

• malfunctioning of the charger itself

• complete deterioration of the battery

• Distortion of reliable contact between terminals.

Therefore, repair of the screwdriver battery is necessary. The causes of non-working situations are determined by measuring the voltage of the tester of each battery. It is recommended that the batteries detected during the measurement be labeled and separated from serviceable copies. Calculating, thus, workable batteries with efficient power indicators, collect from them a complete combat kit.

The following reanimation operations are also recommended: the batteries are charged with a more powerful current than prescribed. Then the batteries are discharged and charged again, but already with a small charging current. Such shock therapy gives a positive effect and brings back to life absolutely hopeless, as it might seem, batteries of screwdriver batteries of various types.

Repair of the battery, which can be made by hand, is shown in the video.