The desire to create the most comfortable climatic conditions in our own home, as well as the desire to save on fuel consumption in the winter, will sooner or later lead to reflections on the need to insulate the cold roof. At once we will notice, there are a lot of options of warming, the choice of the suitable depends on the type of roofing structure. No less important question - how to use the attic space - permanently, as an attic or it will serve as a pantry. If the attic is used as an additional living space throughout the year, it will require the insulation of the roof slopes, if it remains uninhabited - it will be enough to insulate the ceiling from outside, ie. insulate floor loft.

Content

Roof roofs of a private house, insulation options that can be used

Since today the insulating materials are very widely represented, before making a decision about the application of one or the other it will be necessary to thoroughly study their properties and the scope of application, it is not superfluous to consult an experienced specialist. After all, each material except positive characteristics is characterized by certain shortcomings.

Those. before the owners of the house will be the task of choosing the type of insulation optimum for the duration of operation, heat-saving characteristics and cost. All the insulation materials are divided into several types, it makes sense to consider each of them in more detail.

roof insulation with mineral wool, basalt wool, fiberglass heaters

Fiberglass and mineral wool materials are used quite often, an attractive indicator is the high resistance to heat transfer. In addition, the life of such heaters is long enough, they are fire resistant.

Installation of cotton materials is quite simple, in a private house it is quite possible to do it yourself, without recruiting specialists.

The weight of the blocks for sale is small, if you want, you can buy mineral and glass wool materials in rolls.

Among the disadvantages of this type of insulation is the main one is the dependence of heat-saving characteristics on the moisture content of the material. Those. during installation, it is necessary to take into account the need to completely insulate the insulation from the deposition of sedimentary moisture on it.

roof insulation with foam

Polyfoam - a material that attracts simplicity of cutting and assembly. It is extremely light, the plates coming on sale have dimensions of 1x0.5 m or 1x1m, which simplifies the process of their loading and delivery. Foam is fixed with a special glue, there is a choice of plates of suitable thickness: two, three, five, ten-centimeters.

When choosing a foam it is recommended to pay attention to the specific gravity, the level of heat release slowing depends on it. The standard indicators of specific weight for roofing work are 35 kg per cubic meter. Buy more expensive plates with a specific gravity of about 200-400 kg per cubic meter there is no sense, they are designed to build the walls of the house, and not for the insulation of roofs.

The usual foam and extruded polystyrene foam have a very low water retention and low water permeability. Naturally, these characteristics will allow to abandon the hermetic insulation of roofing layers, which is assumed in the version with mineral and glass wool.

On the insulation of the roof foam, details of the work - on the video:

roof insulation with polyurethane foam

In its composition, polyurethane foam is a solidified polymer foam having a cellular structure and belonging to a group of gas-filled plastics. The material refers to environmentally friendly products, it has minimal thermal conductivity, its service life is long, about half a century, installation is very simple.

Rigid polyurethane foam in its composition has fire retardant additives, when hardened, it loses its elasticity, but acquires high heat and noise insulation characteristics. Polyurethane foam is produced by mixing two components: isocyanite and polyol, the first of them is always unchanged in composition, the polyols are used differently, they affect the density, flammability and speed of foaming of the material.

For the thermal insulation of structures it is recommended to use PPU with GOST 307302-2006.

If it is possible to use professional equipment, such as a high-pressure foam generator, then components for the production of polyurethane foam are usually delivered to the construction site, if the proportions of the components are observed, the result obtained when the PPU is made independently does not differ from the factory one.

Foam is used to apply directly to insulated surfaces, or made from it sandwich panels.

The following positive qualities of PPU should be noted:

- very high level of adhesion with metal. concrete and wood, glass and brick,

- the possibility of mounting without the use of fasteners,

- the seamlessness of the heat-insulating layer, i.e. the ability to completely get rid of the "bridges of cold"

- corrosion protection of metal surfaces,

- the possibility of obtaining fragments of the thermal insulation system of a given shape by pressing the liquid PPU,

- the ability to operate the material at temperatures from +200 C to -200 C,

- unwillingness to react with acids, salts, alkalis.

In addition, the use of liquid polyurethane foam is the ability to fill hard-to-reach and inter-wall spaces, isolate all cracks, i.e. places where the usual thermal insulation is hard to strengthen. A small specific weight of the material makes it possible to avoid excessive weighting of structures during the warming.

From the disadvantages of PPU can be noted:

- the need to protect against direct sunlight, the question is solved quite simply if you use sandwich panels,

- when installing it is recommended to apply foam on a warm and dry surface,

- the material is classified as non-flammable, nevertheless, under the influence of very high temperatures, smelting processes can occur in it, i.e. use it for the insulation of baths or boiler rooms is not recommended.

In the solidified form, PPU is absolutely harmless to humans, but it should be carried out with strict adherence to safety techniques and the use of personal protective equipment.

Sputtering starts from the most inaccessible areas, the surface is recommended to be processed several times, the thickness of the sprayed layer should be about 15 mm.

We are watching a video about how polyurethane is sprayed:

loose heaters

This type of insulation systems is used very rarely in our time, because of the complexity and laboriousness of the installation, which requires the construction of special containers for filling the insulation material, which may include: cork, wool, granulated expanded polystyrene, shale material.

Use of bulk materials is rational only if there are numerous bends and irregularities on the roof and ensure the quality installation of mineral wool boards or styrofoam panels will be quite difficult.

Roof insulation with expanded polystyrene

There is another insulation of roofs and walls, so-called. expanded polystyrene.

It differs somewhat from the foam plastic in quality, although the composition of one and the other material is similar, the process of their manufacture has rather significant differences:

- Polystyrene is produced by exposing polymeric raw materials to water vapor, as a result of which the bonds formed between the granules are rather weak, the material can not resist the stresses on the fracture.

- Expanded polystyrene is produced by extrusion, i.e. the granules of the raw material are initially melted, then they are subjected to freon and carbon dioxide treatment, the cells thus obtained have a closed structure, the material is a substance with a solid mass. Extruded polystyrene foam is a high-tech material with a strong structure and high functional parameters.

Installation of extruded polystyrene foam can be performed by different methods:

- on liquid nails, glue or mastic,

- fixation with the help of anchors, racks, nails, umbrellas,

- flooring,

- investing in the crate.

If necessary, a combination of several methods is used.

Thermal insulation of the roof - how to start

Experts recommend: before proceeding to warming it will be necessary to draw up a clear plan and perform some calculations. If the insulation is made during construction, it is more rational to lay the mineral wool or fiberglass before laying the roofing material.

If it is planned to insulate the old roof, then it will be necessary to choose the optimal way of fixing the heat-insulating material to the inner surface. Wooden fragments of the roof will need to be examined for fungal and mold damage, it is desirable to identify cracks in the wood and areas where putrefactive processes are present.

Unsuitable places need to be treated with antiseptic impregnation, subject to restoration.

Do not forget that even the lightest materials will create some loads on the old truss system, make sure that the extra weight will not be critical for them. The heating material should be chosen on the basis of safety factor, which has a rafter system.

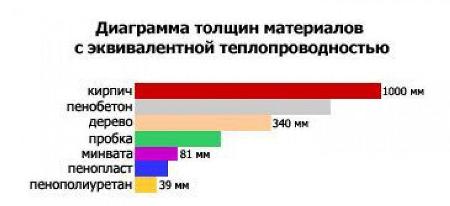

An important point is to perform the correct calculation of the heat transfer resistance. For buildings located in conditions of average climatic latitudes such an indicator should be of the order of 1.6 m2 · S / W. When buying any of the insulation materials is not difficult to know its detailed characteristics.

For example, sufficient thermal protection can be arranged if the thickness of the roof insulation is about 10 cm, this applies to mineral wool or glass wool heaters and foam.

Heat insulation of the attic roof

To make the attic suitable for living in summer and winter time it will be necessary to insulate it.

The solution of this problem can be divided into several stages of equal importance:

- selection of the optimum heat insulator,

- preparation of the roof surface for its installation,

- compliance with the algorithm and technology work.

It is not recommended to choose a heater "by eye" - its insufficient thickness can make the insulation ineffective. We must not forget about the need to install the correct ventilation - increasing the humidity will lead to the development of putrefactive processes in the wood from which the rafters are made.

To insulate the attic roof, you can use the same materials that are used to insulate the roof of a private house from the inside, but on condition that they meet the following requirements:

- have a minimum thermal conductivity,

- differ insignificant water permeability,

- have a negligible weight,

- not to be prone to fire,

- to maintain its performance characteristics for a long time,

- be resistant to sudden changes in temperature.

Simplify the calculation of the thickness of the insulation for the roof skylight, using the online calculator, it is not difficult to work with it, you will need to set the following parameters:

- the area in which the structure is located,

- thickness of floors and walls of the house,

- material from which the walls are erected,

- the insulation material you choose.

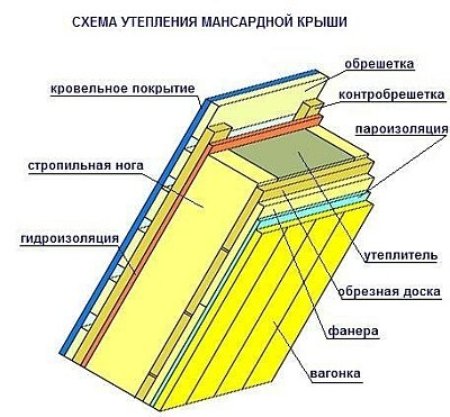

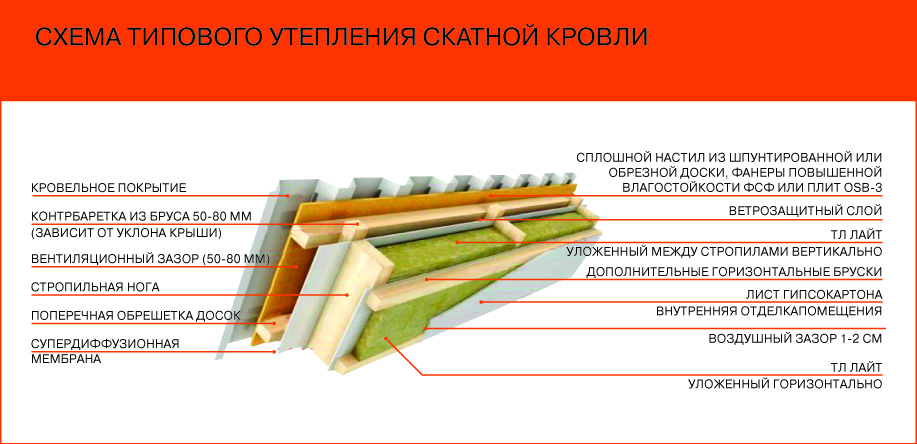

If you are motivated by the desire to equip a full-fledged residential building under the roof of the house, first of all you will need to lay the waterproofing material, it will protect the warming layer from possible penetration of moisture. The membrane is laid on top of the crate, for the use of bars.

Too much pull on the membrane should not be allowed, it is permissible for a slight sagging, not exceeding 10 cm. Laying the plates of the insulation material is made between the rafters, without the formation of gaps. It is best to stack the material in two layers, and so that the second layer completely overlaps the seams of the first.

After fixing the heat insulator, a layer of vapor barrier film is laid to protect it from condensate. Fastening of the vapor barrier layer is carried out to the crate by means of a stapler. Joints should be fixed with an adhesive tape. Installation of a vapor barrier is required in cases where mineral or glass wool is used as insulation material, installation of waterproofing is necessary in any case.

The waterproofing should be made of superdiffusion membranes that let steam out, but prevent moisture from entering inside. During installation it is necessary to ensure the presence of a ventilation gap between the layer of waterproofing film and the roofing material, its thickness should be of the order of 4-10 cm. It will ensure the possibility of removing excess steam from the warming layer.

Performing the insulation of the attic roof is easiest at the stage of building a house, this point should be added to the project. It should be noted areas that will be exploited as residential and. hence subject to finishing.

If the area of the whole attic, including the area under the roof slopes, is used as the residential area, then the total area of the skates should be insulated. If the premise is cut off, then the insulation can be made according to special schemes, and it will be necessary to equip additional ventilation.

More information on the insulation of the attic roof - on the video:

Helpful Tips

Although at first glance the arrangement of the roof insulation system of a private house is quite simple, nevertheless, inexperienced builders often fail to avoid mistakes.

Therefore, it is not superfluous to know that:

- use of defective sheets of foam or damage to already installed plates is fraught with the appearance of cold bridges,

- the tightness of the thermal insulation can be disturbed due to improper selection of the width of the thermal insulation material,

- a polyethylene film installed instead of a vapor barrier membrane will promote the appearance of condensate,

- negatively affect the result of the violation of the order of work and the use of poor-quality materials.

Summing up, it should be noted that when choosing a thermal insulation material, it is necessary to take into account not only its heat transfer resistance, but also environmental friendliness, soundproofing properties, fire safety.