A wide variety of ready-made pools allows the consumer to choose the design that suits him. If you plan to install a capital structure, then a good solution will be to select a composite pool. Models of composite pools can become a real decoration of the site, at the same time they do not require large installation costs and are easy to operate.

Content

What is a composite basin?

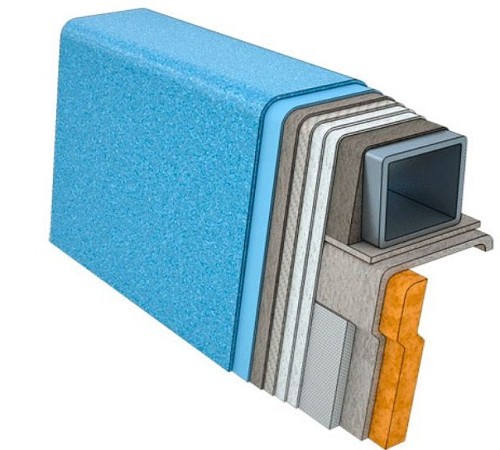

Composite pools are open artificial tanks for swimming. Such designs can be large in volume and area of the water mirror, they are durable and durable. The one-piece bowl of the pool is made of reinforcing materials: fiberglass, glass fabrics, glass wool, impregnated with composite polyester resins. Fiberglass gives the product strength, which is 17 times higher than the strength of concrete. Thanks to fiberglass, the load is evenly distributed over the entire surface of the bowl. Such reinforcing materials are not destroyed for a long time under the influence of the aquatic environment, while being environmentally safe.

Composite pools are completely cast in the enterprise, their technology is close to the production of small yacht and motorboat hulls. Such constructions are elastic and light, but at the same time, unlike prefabricated pools, the body of the composite bowl is monolithic and much stiffer. The elasticity of the material contributes to a change in the shape of the structure without the occurrence of cracks in the housing. At the choice of the buyer composite pools with skimmer and overflowing water treatment system are presented. In addition, the water in the composite basin is treated by special means under the general name of chemistry for swimming pools.

Covering the basin of the pool is smooth, it can be made in different colors. In principle, the bowl does not need additional decoration, but the best composite pools can be lined with exclusive mosaic, partially or completely.

advantages of composite pools

- High strength, elasticity, lightness of the material.

- Integrity, tightness, rigidity, structural stability.

- Increased frost resistance (up to -40 ° C).

- Excellent thermal insulation performance, additional warming of the pool is not required.

- Stability of the material to corrosion, ultraviolet, aggressive influence of water and environment.

- Hygienic material, resistance to mold and fungus attack.

- Long service life with a minimum of maintenance costs.

- Easy care and high maintainability.

- Quick installation and the possibility of dismantling.

- Ecological cleanliness and safety.

- Availability of the plant in difficult conditions.

- Possibility to install a swimming pool with your own hands.

- A wide range of products, affordable price.

- The ability to use in winter conditions with the equipment of a concealed pavilion.

Composite layers of the basin bowl

To the disadvantages of composite basins can be attributed the limited size and shape of the bowl. Since the pool is delivered to the installation site by transport, its dimensions are very limited: the length is about 8-10 meters, the width is up to 5 meters. Also, this is a ready-made design, so the consumer has to choose the shape of the bowl from the variants suggested by the manufacturer. However, such minor drawbacks do not affect the popularity of composite pools, customer reviews take them to the first places in popularity among all ready-made structures.

How to prepare for delivery of the pool

Delivery and unloading of the basin is best entrusted to qualified specialists. Most likely, the employees of the company on which the pool is ordered will give all the necessary instructions on what is needed to bring a large bowl. Let's enumerate what will be required:

- Provide free access to transport.

- Provide free space for crane operation.

- Create comfortable conditions for the work of specialists.

Choosing a pool, you should determine its size, not only based on personal preferences, but also to think carefully about the way of delivery and installation. Too large a bowl can simply not pass through the dimensions in a small street so as not to cause damage to the product itself and to its neighbors. Therefore, when delivering it is worth considering:

- Dimensions of the pool basin together with the vehicle.

- The width of the road, all the turns and bends.

- The height of the wires of power transmission (not less than 4 m), the presence of trees and piles.

Attention! According to the safety regulations, it is forbidden to perform unloading operations in a gusty strong wind.

Unloading the pool, you should avoid the impact of the font on the ground and nearby objects. Unloading can be performed with or without a frame. The length of the rafters should not be from 4 meters.

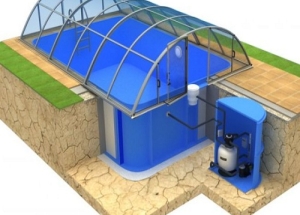

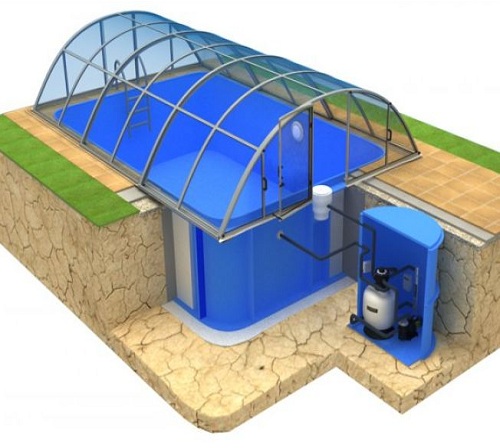

How to install a composite pool for a summer residence

The huge plus of composite pools is that they are ready-made structures and do not need to spend money and efforts on their construction. Advantage of solid-cast composite basins in front of other structures in quick installation. Composite bowl is a sealed product and is able to last for no more than 25 years. Install a composite pool by yourself can be in several versions: with full or partial penetration, as well as on the surface of the site. The choice of installation method depends on the individual needs and wishes of the consumer.

Attention! In the place of installation of a composite basin, underground and ground communications should not pass: gas, water, electric, telephone and Internet cables.

When choosing a place for a swimming pool, you should correctly approach such issues as:

- Organization of natural lighting

- Availability of summing up all necessary communications: electricity, water supply, sewerage.

- The possibility of creating a shelter or a covering zone.

Stages of installation

choosing the best place for the pool

In principle, it does not matter where the assembly of the composite basin will be made, but if you approach the site selection scrupulously, you will be able to avoid some additional work. Ideally, the location of the pool should be even. It is advisable that there are no trees and high bushes nearby - the leaves and branches will pollute the water, and the roots may deform and damage the pool basin.

Attention! If groundwater flows on the ground close to the surface, drainage should be carried out along the entire perimeter of the pool. The drainage system protects the pool basin from deformations during groundwater movement.

site marking and foundation pit preparation

Before digging the foundation pit, you should determine the level of the basin of the basin according to the installation plan. After that, you need to mark the place under the bowl, proceeding from the chosen finished form. Also, when designing a foundation pit, not only the depth of the basin's basin is taken into account, but also a pit for the necessary maintenance equipment.

The pit can be dug by hand or with the help of special equipment. Its dimensions depend on the chosen model of the composite basin and should be slightly larger than the cup itself by 300 - 500 mm. The walls and the bottom of the excavated pit are carefully leveled, cleaned of loose earth, stones, plant roots and compacted.

Attention! It should be very carefully approached to calculate the necessary depth of the foundation pit under the pool. If you choose an extra land, do not put it back.

foundation preparation for the bottom of the pool

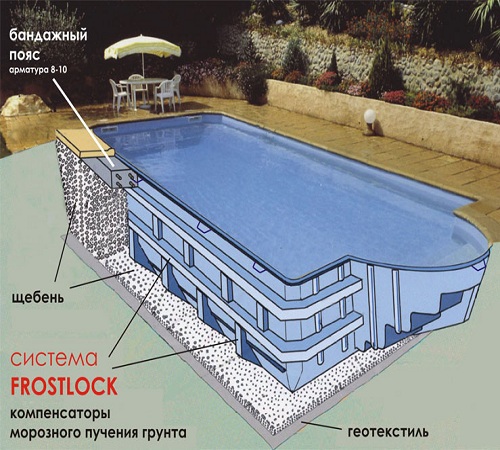

The depth of excavation under the basin is calculated from the depth of the bowl itself plus the addition to the substrate under the bottom. The depth should be increased from 200mm to 500mm to create a drainage gravel "cushion" (fraction 5/10) and a concrete foundation. "Pillow" is filled with a height of 50 mm to 250 mm, then works are carried out to mount a reinforced concrete base in height from 150 mm to 250 mm.

The concrete base can be insulated with sheets of expanded polystyrene or other moisture-proof dense heat-insulating material.

installation of the bowl of the composite basin

At this stage, the basin is lowered into the prepared pit. Such work should be done very carefully with the help of a crane, or manually, depending on the size of the shell.

After diving, the leveling of the structure is performed - the level of the upper bowl of the bowl is checked, so that there is no distortion.

Mirror of water poured in the future, should be parallel to the upper side of the pool. Such a level check can be performed in various ways: a hydraulic level, a laser or optical level. Also, when installing the pool bowl, it is necessary to provide support for the steps, so that they do not sag under their own weight. As pillars are installed columns that are laid out of bricks, or other improvised materials.

installation and connection of mortgage elements and communications

At this stage, work is under way to install all necessary communications, standard technical equipment and embedded elements necessary to ensure the operation of the pool and create additional amenities when it is used. The equipment can be installed directly near the pool, or in a specially designated place, then additional work will be required to equip the premises.

As additions can be installed various technical devices and entertainment: hydromassage, lighting, geysers, aquamusic, countercurrents, slides, etc.

reservoir basin fixation

This step should be approached very carefully. Along with the first backfilling cycle, a certain amount of water must be filled in the pool.

After installing the basin of the pool between it and the walls of the pit, there is space, which should be properly filled with a special solution. It is here that the advantage of the composite basins affects - the capacity additionally acts as a fixed formwork. In this case, composite pools for cottages do not need additional waterproofing, since they initially have excellent sealing properties.

Sinuses are filled with a damp cement-sand mixture (1: 5). When backfilling, use the pole and pierce the mixture in depth to eliminate voids. Sand mixture is filled slowly, gradually and evenly from all sides. At the same time, it is necessary to fill the basin of the pool with water with an anticipation of an average of 20 cm. That is, the level of water to be filled should always be higher by 20 cm from the mixture to be filled. With this filling, the deformation and misalignment of the walls of the tank are completely excluded. It should be very carefully monitored so that the sides of the bowl do not extrude inwards.

Do not tamp down the mixture, the shrinkage should be natural, so it is best to perform such work for several days, and do not cover all the empty space with a rhinestone.

Decoration of the adjacent zone. Bandage belt

Adjacent territory around the pool begins to equip after the mixture is dried and the pool has shrunk completely. If you plan to install composite pools with a canopy or a sliding pavilion, it should be borne in mind that the base must be reinforced concrete and designed for the dimensions and weight of the structure.

The area around the pool should be strengthened, it is necessary to have a strong structure and ensure a high quality masonry cladding material. A reinforced concrete belt is poured around the perimeter of the tank. It is he who serves as a strengthening bandage: the height of its pouring is 20-25 cm, the width is about 70 cm. For rods, 8-10 mm in diameter are used. The fittings are attached to the metal profile, or to the pre-installed fittings. Further work is done on the lining of the area around the pool. It can be any waterproof material, the most popular are ceramic tile and granite.

Contents in winter conditions

Water from the composite basin does not drain for the winter. Ice in the basin basin compensates for pressure on the walls of the frozen ground, thereby preventing the bowl from moving and deforming. From pipes and communications all water must be drained. In place of all injectors, it is necessary to install plugs so that the water does not go back into the pipes during a thaw. Pumps are removed, the upper water intake is turned off.

It should be noted that all the recommendations for the care, operation and conservation of the composite pool for the winter are prescribed in the instructions accompanying this product.