The qualitative connection of wires during electrical work can be considered a strategically important task. You can and should immediately trust the professionals who with their eyes closed distinguish between copper and aluminum wire. And can still try to make direct contact with one's own hands?

Content

Contact! There is a contact!

When carrying out repair or electrical installation works, it is almost always necessary to connect the wires. The connection between the wires should provide the necessary maximum mechanical strength. In this case, the electrical resistance of the contact point should be minimal.

Such properties should be maintained during the entire operation of the wiring. But external changes in humidity and temperature, as well as vibration, act negatively on contact connections. At the same time, contact resistance may be weakened, which leads to negative consequences. How to properly connect the various types of wires and materials, and what are the ways to connect them?

What are the electrical wires

An electric wire, without the existence of which an apartment is impossible, is a current conductor, therefore it can be uninsulated and isolated. The wire has in its composition one core or several wires (wires). Aluminum and copper are used for the manufacture of wires by the factory method. According to the purpose, the following types of wires are distinguished:

• installation wire

• electrical cable

• cord

• non-insulated wire.

The installation wire is presented in the form of an isolated bundle and is intended for wiring in an apartment. The wiring can be installed for concealed and open wiring.

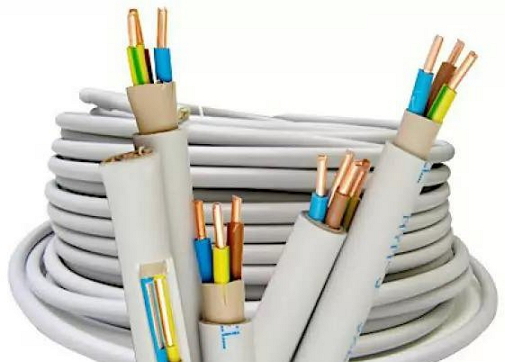

The electrical cable in the composition has several insulated wires, are enclosed in a common protective shell with the specified properties. To enhance protection, the electrical cable is placed in the metal hose.

An electrical household cord is a flexible cable of small dimensions with flexible conductors. An electric cord is used and is used to connect household electrical appliances in an apartment.

Unfortunately, the electrical wires are not durable, as we would like. Therefore, for conducting installation or repair work, certain methods of connecting the wires are used.

Ways of connecting wires

There are the following ways of connecting the wires:

• with the help of twisting

• with the help of clips of connecting insulating

• self-clamping terminals

• Solder connection.

Scrolling

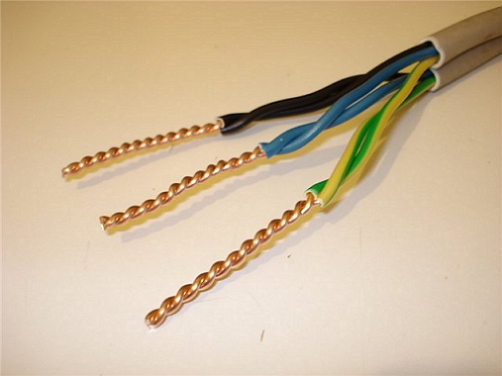

The most simple and proven is the ancient "grandfather" way of joining twist. To make a connection using this method, it is enough to take two wires, remove the insulation layer 5 cm and twist the bare wires together. However, such a "twisted pair" of copper and aluminum wires is unacceptable. This is due to a significant difference in the coefficients of thermal expansion of wire materials. In copper, the coefficient of thermal expansion is 16.6, and for aluminum, 22.2.

An apparent significant difference leads to a disruption in contact. In addition, the atmospheric influences outside the room for contact with copper and aluminum are significant. All this contributes to an increase in the transient resistance, the occurrence of local heating at the junction point and the subsequent destruction of the connection. This twist will last, alas, not for long.

Wiring options are shown in the video.

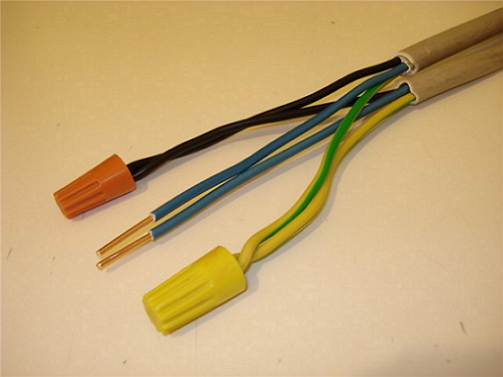

Connecting insulating clips

Connection by means of connecting insulating clips (PPE) is used when connecting one wire strand, with a minimum cross-section from 2.5 mm to max. 20 sq. M. Such connecting clamps are structurally provided with a body made of polyamide or refractory PVC. Inside the molded anodized spring is conical. Additional insulation is not required in this case.

Terminal blocks

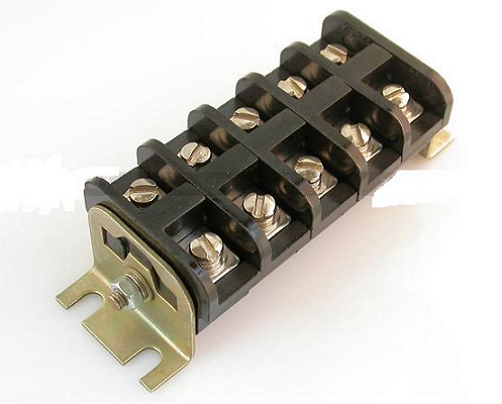

According to the PUE, terminal blocks are used to connect the wires. There are the following main types of terminals, recommended for connecting the wires of the electrical wiring of the apartment: screw, self-clamping and insulating. The connecting screw type of the terminal block is the most demanded and is used for connecting wires for junction boxes. Screw terminals are made of polyamide, polycarbonate and polypropylene.

Screw connection terminals when working with aluminum wire are recommended not to use, because the wires are deformed and can break.

With the help of self-clamping terminals it is possible to connect wires with cross-section up to 2.5 sq. Mm. The operating current flowing through such wires can reach a value of 24A, and the working load is up to 50 kW. The total connection number of places for self-clamp terminals can be up to 8. This greatly speeds up the installation of the wiring. Compared to twisting, this type of terminal block takes up more space in the hanging boxes.

When repairing electrical wiring with aluminum wires, there is often a situation where it is necessary to connect the copper and aluminum wires. How to act in such chstystrechayuschemu case? To connect the wires used special terminal blocks and bolted connections.

Connections bolt type consist of three working plates, between which the clamping of wires. What are the advantages of a bolted connection? The main advantage is that there is no need to break the main line. You simply unscrew the two mounting bolts, mount the wire between the plates, and tighten the bolts in place. The outgoing wire is located between the middle and the last plate.

The main types of terminals for connecting wires can be found here.

Soldering

And, finally, soldering is the most reliable and lasting way of connecting wires. The soldering process increases the installation time, however, this method is considered reliable for the Euro-repair class electric wiring.

The technology of connecting wires with soldering is shown with reliable accuracy in this video.