It's one thing when you moved into a house that was designed and turned out www.arkos-proekt.ru and a completely different question is faced by the owner who builds the house on his own and must solve many issues of life support for the future of the house on his own in the course of construction. An important factor is how to organize the heating of your own housing. Consider the option of heating using a solid fuel boiler. To make a solid fuel boiler for a house, it will not be enough to find the necessary drawings and materials. First of all, it is necessary to think whether this type of unit can be manufactured independently, taking into account the requirements required for installation and connection. If the councils of the Master awakening in you give birth to creative potential, then you can start the work safely.

Content

What is a solid fuel boiler

Solid-fuel household boilers from the manufacturer are material-intensive and expensive units using wood waste and fuel briquettes as fuel.

The principle of dry distillation, which takes place in the physical exothermic process, is based on the operation of solid fuel boilers. The gas-generating process in boilers allows achieving a powerful efficiency of up to 75%. To achieve a significant efficiency allows the use of high-quality solid fuel and a well thought-out solid fuel boiler system.

Compared to existing heating boilers, a wood boiler provides the following benefits:

• modest consumption of the cheapest fuel

• the combustion time of the unit up to 10 hours with a single fuel load

• Eco-friendly combustion of fuel mass with low ash content

• Good combustion efficiency.

In order to understand what such a boiler is, it is necessary to consider the device and methods of self-connection.

Installation of a solid fuel boiler system

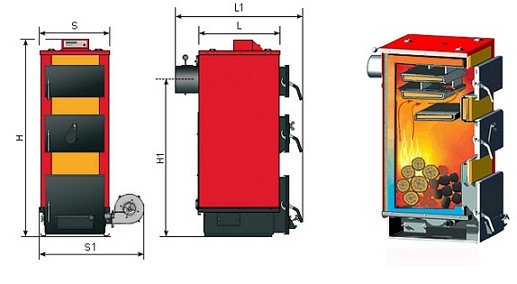

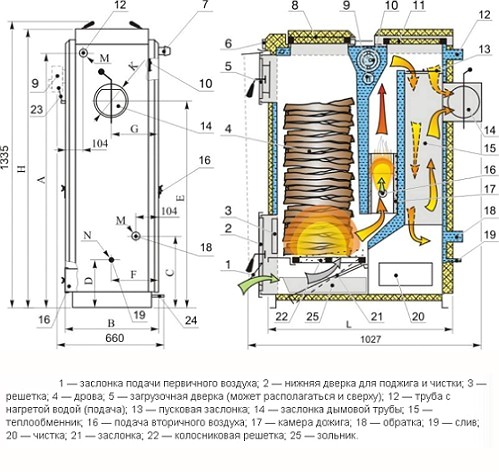

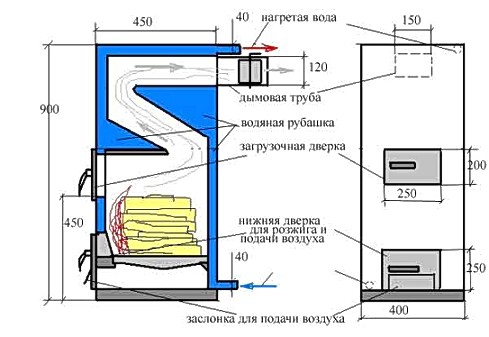

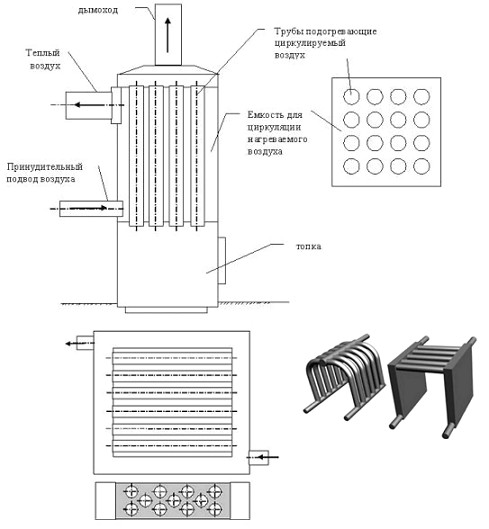

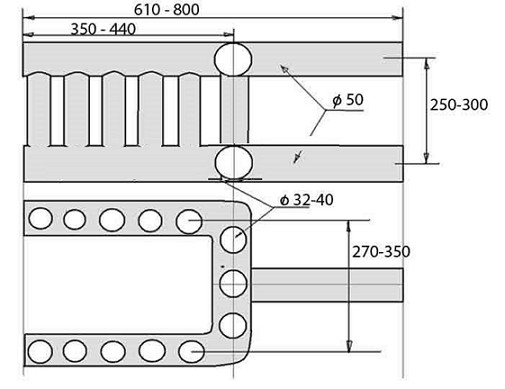

The device of solid fuel boilers can be considered traditional: the furnace, above the furnace there is a ash pan. The furnace is separated from the ash pit with an ash-blast grate made of cast iron and equipped with a door for solid fuel loading. A heat exchanger is located slightly above the furnace along the route of the combustion products.

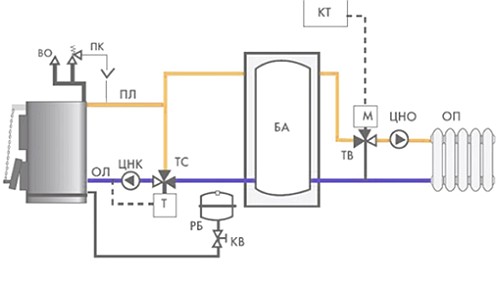

Recall that the fuel route can have frontal or top loading. As a heat exchanger heating boiler use a water jacket, rectangular or cylindrical tank, coil and pipes. When connecting to the circuit of the accumulating heat-insulated tank, it is possible to use heated water to heat the room.

What determines the efficiency of solid fuel boiler

It is not difficult to guess that the efficiency of the operating boiler will depend on the scheme of its connection. One combustion chamber in a solid-fuel unit presents certain requirements for the layout of the boiler.

For the scheme of organization of work and connection, the key points are:

• location of the combustion chamber and working off the fuel route

• selection of the optimal air supply method

• correct connection

• Fuel material.

Recall that the fuel consumption for solid fuel boilers is:

• Anthracite fuel - 2.5 kg / h

• coal - 3.0 kg / h

• wood - 6 kg / hour.

The best solid fuel boiler can be compared to the "pumped-up account" on the Internet. The fuel arrives on time and follows exactly along the specified route, bypassing the dusty alleys of spam and the services of bots.

How to connect a solid fuel boiler

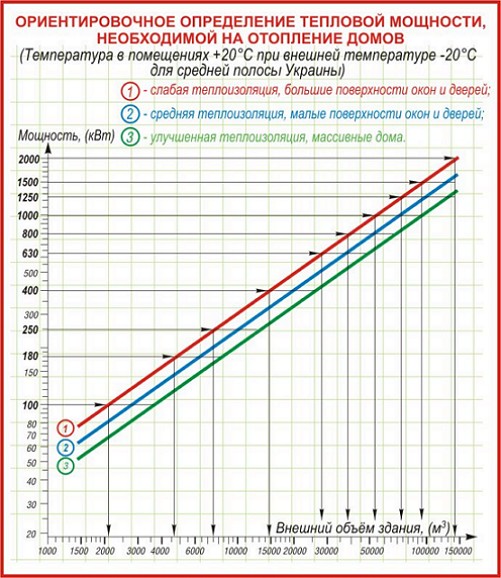

Connection of any heating equipment, and solid fuel boilers is no exception, begin with the calculation of the heat loss of the room and the boiler's capacity.

calculation of boiler output

According to the calculation procedure for determining the capacity of the heating equipment in the existing area of the room where the unit is planned to be installed, an average power factor is used.

Naturally, such an "average indicator for the hospital" could be missed, but this should not be done. Therefore, to determine the power of the boiler can be according to the formula:

Wk = S * kW / 10

where: (kW) averaged indicator equal to 0,7-0,9 kW for 10 m3 for southern regions, 1,5-2,0 kW for northern areas, 1,2-1,5 kW for central ones.

For example, in order to heat a room located in a central area with an area of 100 sq.m, a boiler will be required that:

Wk = S * kW / 10 = 100 * 1.4 / 10 = 14.0 kW.

However, this calculation does not take into account the heat loss of the building and the building material of the constructed building. Let's say that the heat loss table is recommended to be found in the reference books.

In addition, it does not hurt to remember that the efficiency of the unit is affected by:

• Fuel quality

• direction and power of the wind

• chimney construction

• quality of insulation of a private home.

we connect the boiler from the manufacturer

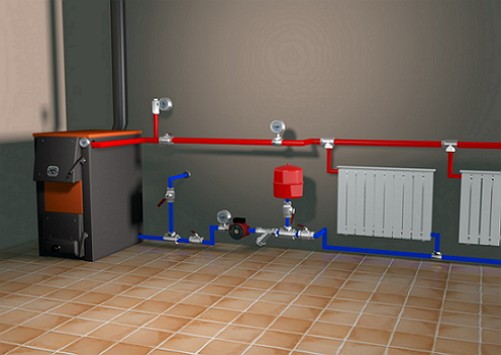

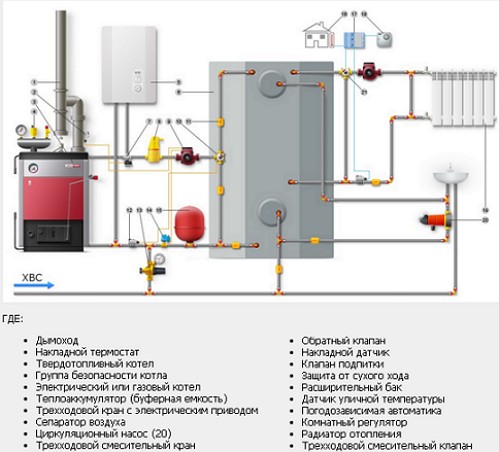

After the purchase of the boiler, the installation of the unit at the site produces the pipe routing. Installation begins with the installation of a reverse circuit. Boilers solid fuel from the manufacturer provide a balancing valve, which allows you to install the "economy" mode, thereby increasing the length of time the heating unit operates with a single fuel tab.

During the subsequent installation of the pipes of the system towards the boiler it is necessary to take into account and calculate the slopes of the heating system. It is especially important to comply with this rule for a heating system with natural circulation. It is also necessary to remember when strapping the boiler that the distribution of water from the heat exchanger is recommended to be placed above the inlet of the reverse circuit.

We produce and install a solid fuel boiler

simple construction of solid fuel boiler with water jacket

A simple boiler design is an assembly in which the body and heat exchanger are made of welded steel sheets creating a water jacket contour. The maximum heat transfer coefficient is achieved by increasing the area of direct contact with the furnace flame and the heated gas-air mixture.

To do this, the design should provide for the arrangement of characteristic internal protrusions (reflectors).

To do this, an additional slit-like register made of sheet steel by the welding method is placed around the combustion chamber, which is located in the upper part of the boiler.

How to assemble and weld a boiler of steel sheets, shown in the video.

we have the boiler correctly

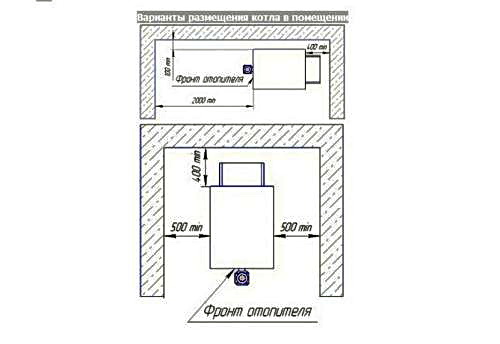

According to the regulations and rules, as well as the requirements of SNiP II-35-76 "Boiler installations", PPB-01-03 "Fire Safety Rules", it is recommended to place the boiler in the following way:

• recommended manipulation distance in front of the boiler - 2000 mm

• The minimum distance between the wall and the rear, side parts of the boiler should be 400 mm

• The ceiling height in the boiler house is 2000 mm.

preparation of the foundation for the boiler

Homemade solid fuel boilers are in most cases produced by large-size floor standing. Therefore, it is recommended to build on the floor of a special room for the boiler foundation of non-flammable material. It is recommended to make a foundation pad 20 cm wider than the base area of the boiler.

installation and connection

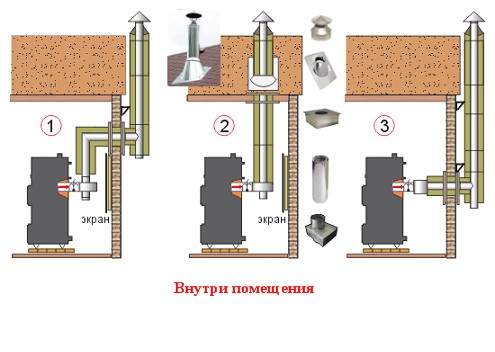

After the boiler is assembled and installed locally, it is connected to the chimney and connected to the heating system.

Properly install a self-powered solid fuel boiler will help the video.

The strapping of the solid fuel boiler should be made available to specialists.

How to make a binding of a solid fuel boiler will show a video.