Any home wizard always contains the tool in working order. Especially this refers to the knife planes of the hand or electric. You need to learn how to properly and accurately grind the planer knives. What are the tools and tools for sharpening the tool, and how to learn how to use it?

If the knives of the planer are blunted

The working capacity of the planer largely depends on the sharpening of the knives. A knife or a planer cutter represents a metal blade that is located to the surface of the processing at a certain angle.

The working position of the tool is an extended and adjustable part of the knife. The knife protrudes through the slot through which the spent chips come out. Clamping of the planer knives is carried out using simple clamps. The equilibrium system of arrangement of the basic elements of the plane creates a sufficiently efficient unit, until the master feels that it is time to sharpen the knives for the plane. How to determine if the knife of the plane is blunted or not?

Difficult diagnostics blunt knife plane does not require. It is enough to consider the cutting edge (chamfer) of light. By turning a chamfer around the edge, you can find a shiny thread-like strip that will signal that the edge has become blunted. This is easy to explain: the angle of sharpening the knife of the planer is 30 degrees. Professional carpenters sharpen the bevel without measuring the angle, relying on their own intuition and achieving the necessary ratio between the width and thickness of the knife.

When sharpening knives, you must observe the balancing and geometry of the blades. If you can not boldly hand-grip knives manually, the device and the device for sharpening knives for the plane will come to the aid.

Learn more about the knife planers will help you video.

Learn to sharpen the knives of the planer is not difficult. It is enough to study the design of devices, devices and sharpening machines, as well as to be able to securely fix the knife blade.

Adaptations for sharpening

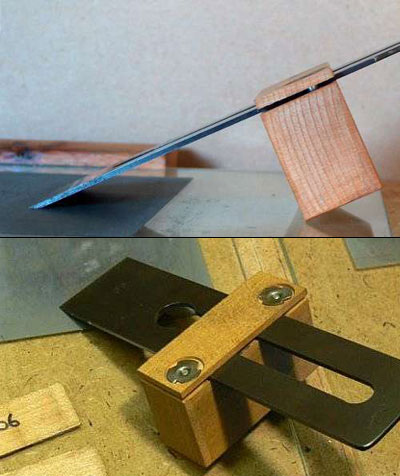

The simplest, and therefore accessible, manual device for sharpening knives can be called a wooden block, in the upper part of which a planer's knife is fixed.

This device has two points of contact: at one point it is supported by the sharpened blade on the abrasive, and the second point by the angle of the bar. Primitive design and manual movement of the device, however, allow to produce a good sharpening of the planer knives. It should be borne in mind that the angle of sharpening depends geometrically on the height of the wooden block above the surface of the abrasive, as well as the distance to the attachment point.

When sharpening, the knife blade of the piece of iron should be straight.

There are also the following tools used for sharpening:

• circle grinding

• Clamp for sharpening

• barrel roller

• honing board

• sharpeners with front and side clips.

Circle grinding is an abrasive wheel with a diameter of up to 60 mm with a circle thickness of up to 18 mm and a hexagonal shank. For ease of sharpening, the circle is equipped with a tapered groove, located along the circumference. The grinding circle is made of silicon carbide. For sharpening, an electric drill is used as a driving element.

Clamp for sharpening it is intended for reliable clamping of knives for a plane on a sharp stop. The clamp has 3 working positions, which allow you to install a rod that aligns under the desired working angle of the grinding. The angle of sharpening can vary from 30 to 90 degrees. The clamp is attached to the screws located on the plastic gaskets. The material of the clamping is anodized aluminum.

Roller barrel It is intended for elimination of sharpening defects on a sharpened workpiece. The roller has a characteristic shape that allows you to eliminate the "paths" formed after sharpening with a sharpener for 3 visits. This keeps the angle of 90 degrees between the side parts of the knife and the cutting edge.

Hone honing bar is intended for the substrate function for abrasive paste. Convenient geometric dimensions and material of manufacture - low-carbon stabilized steel ensure flatness on the entire surface of the sharpening up to 0.127 mm. Unlike water stones, the bar does not need to rub the surface when sharpening. It is possible to glue the bar to a large surface area, which provides the best comfort when working.

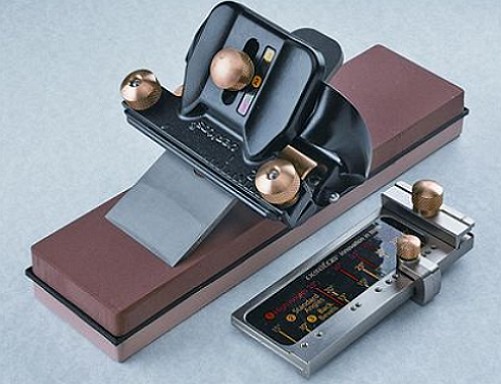

Veritas Sharpening System Sharpener with a front and side clamp is designed for sharpening knife planes and joinery, except for blade knives from Japanese manufacturers. The sharpener is a web that can be clamped together with the blade of the knife in front or on the side. The sharpener is equipped with a roller, which prevents any damage to the grinding stone. Sharpening of knife blades is carried out due to the template of the cornering with the possibility of manual adjustment.

It should be noted that when working with sharpening devices, it is necessary to pay attention to the reliable fastening of knife blades.

How to learn to sharpen planer knives with the use of gadgets will help you this video.

But the special interest in sharpening knives is caused by work on the grindstone. You can learn how to work on a grinding machine by reading the instructions.

Grinder Tormek

The Tormek is a low-revving grinding machine with a powerful motor and significant torque. The machine allows to carry out grinding work continuously for a long period of time. High speed of sharpening is ensured by low speed (up to 90 rev / sec) and water cooling of the cutting edge of the sharpened tool. The device and the principle of the machine for sharpening knives for a plane is quite simple. The sharpened tool is clamped into the holder.

The holder with the fixed tool is fixed on the universal support. Then the grinder is turned on. Sharpening of knives or other tools occurs at low speed using a grinding wheel immersed in water. The grinding process is visible, at any time it is possible to adjust and control the clamping force, the width of the chamfer and the speed of rotation of the grinding wheel. When the tool is sharpened, the tool is completely burned. Using a variety of grinding stones allows you to sharpen any metal.

You can learn how to work on a sharpening machine for several visits. Therefore, knife sharpening with their own hands will not be difficult. For greater confidence in the work and practice of sharpening the knife planers, you can see the video.

Recall that grinding works always require attention and compliance with safety regulations.