One of the most important measures in the construction process is to protect the structure from moisture. This is an indispensable condition for ensuring the safety and durability of the building. Within the framework of this publication, we will talk about waterproofing pasting materials - their types and features, applications and technology for gluing roll materials on the bases of various structures.

Content

Oakleychnye waterproofing materials, applied to the surface, are a continuous waterproof carpet. The material is glued in one or more layers on a specially prepared surface. Bitumen-containing, bitumen-polymer or polymeric mastics are used as an adhesive.

Rolling waterproofing: technology of gluing on the base

The device of a roll waterproofing provides for carrying out of thorough preparatory measures. Before proceeding to waterproofing works, the surface of the base is leveled, cleaned and dried. From the surface it is necessary to remove all the influxes, if the armature acts - to cut off, to seal the depressions. Deformation seams are sealed with a sealant, the brickwork is plastered with a cement-sand screed. As we already noted above, different types of mastics are used for the labeling of waterproofing materials.

If mastic is used with bitumen content, it is necessary to take into account the ambient temperature during the waterproofing works. A necessary condition - the softening point of bitumen should be 20-25 degrees higher than the air temperature.

The waterproofing of the substrate begins with the application of bitumen mastic to the substrate. The thickness of the mastic layer should be approximately 1.5 mm. After that, roll a roll of waterproofing and paste it on the base. The mastic also processes the decomposed material. The roll is rolled out and completely adhered to the base. If necessary, excess material is cut off. If multi-layer waterproofing is required, then the laying of all the following layers is carried out in a similar way. Cloths glue only in one direction.

The list of rules that must be adhered to when sticking the roll waterproofing materials:

- In the case where it is necessary to treat a horizontal or inclined surface having a length of more than 10 meters, the material is glued using special tools.

- On a vertical surface, the material must be glued only from the top down, previously cutting off pieces of the required length.

- Cloth material overlaps. The horizontal seam should be not less than 200 mm, longitudinal - not less than 100 mm.

- After the material is pasted, the edge must be ground and then treated with a layer of mastic up to 1.5 mm thick.

- The pasted waterproofing can not be subjected to the effects of tensile and shearing loads.

- To protect the pasted material from mechanical impacts and landslides, special protective structures are constructed of concrete, brick or reinforced concrete.

- The coating, which is planned to be protected with cement or silicate material, needs to be wiped over the hot bituminous mastic with quartz sand of coarse fraction.

Types of rolled waterproofing materials: bitumen-containing materials

Waterproofing roll bituminous is most known, widely distributed, relatively cheap and easy to operate. This type of material includes a waterproofing - roll pasting waterproofing material.

A hydroisol is a non-rotted glass fiber with a long service life. The material is impregnated on both sides with bitumen, which is mixed with a plasticizer. Due to this combination of materials, the hydroisol is elastic and has high resistance to cracking.

This is a universal waterproofing material, which can be used for almost any type of coating. Manufacturers produce two types of waterproofing: two-sided and one-sided. Double-sided waterproofing has a coating of polymer protective film on both sides. During the heating of the roll, this film melts. A two-sided hydroisol is used mainly for waterproofing basements, foundations and other areas subject to intense moisture exposure.

One-side waterproofing has a powder of mineral or granite chips on one side. It provides protection of bitumen from direct sunlight.

The main areas of application of waterproofing:

- Waterproofing roofs.

- The foundations.

- Pipe.

- Tunnels.

- Mostov.

- Wells.

- Swimming pools.

- Other objects in the open air.

Bitumen-polymer waterproofing materials

The main difference between bitumen-polymer materials and bitumen-containing materials is the saturation of bitumen with special polymer additives, which significantly increase the protective characteristics of the material. In the production of bitumen-polymer materials, two types of polymers are used: elastomers and polymers. These additives give the material additional elasticity at negative temperatures and high heat resistance.

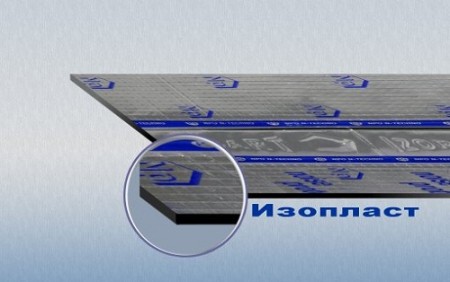

Bitumen, in the process of production of which polymers are used, is a component in the manufacture of Izoplast - a high-quality waterproofing material with increased resistance to atmospheric factors, especially to ultraviolet radiation.

Heat resistance of the Izoplast is not less than 1200С. Due to its characteristics, Izoplast is effectively used in the southern latitudes of Russia.

In the case where waterproofing materials are glued with a continuous carpet, it is not always possible to avoid the formation of blisters, which significantly reduce the quality of insulation. To solve this problem, use an auxiliary perforated Isoplast P.

If we say bitumen-polymer roll waterproofing technonikol, then it is necessary to mention the material "Technoelast Alpha", which is widely used for the processing of foundations.

Membrane (polymeric) waterproofing

Polymeric waterproofing materials are a kind of pasting roll materials created with the use of modern advanced technologies. They are thermoplastic membranes or membranes of vulcanized rubber, reinforced polyethylene lashes and other materials. In contrast to the above materials, membranes and films have a very small thickness, which ensures a practically complete absence of shrinkage during compression. Polymeric waterproofing materials - one of the most modern, but at the same time expensive waterproofing materials. They are distinguished by their strength, durability, and relative elongation. Produced in soft sheets or rolls.

The disadvantages of this type of waterproofing materials include the need for preliminary treatment of the substrate with a primer, or the presence of an air layer for ventilation. This is explained by the fact that polymer materials have a very low vapor permeability, and can simply come off under the pressure of water vapor.

Roll-up waterproofing of the foundation

Oakleye roll waterproofing materials are widely used to protect the foundation from the impact of groundwater. The waterproofing of foundations with backing materials is made in the form of a multi-layer continuous carpet. Cloths are connected with each other by mastic or adhesive compounds.

Rolled waterproofing can be attached to the foundations of the foundation in one of the following ways:

- Using mastic or glue.

- Fixing on a self-adhesive layer.

- By fusing by heating a polymer or bitumen layer that is applied to a waterproofing.

How to choose a roll-on waterproofing for the foundation

In order to properly choose the material for the waterproofing of the foundation, it is necessary to know exactly the conditions of its operation, the type of soil and its humidity. Rolling waterproofing materials can be used for both horizontal and vertical waterproofing. In specialized stores you can buy waterproofing materials on a variety of bases, characterized by resistance to mechanical damage, resistance to aggressive chemicals and the pressure of groundwater.

For foundations made of concrete slabs, waterproofing of a high-strength roll-on roll with a polymeric or glass-fiber base is used. For heavily buried foundations located in places of strong pressure of groundwater, roll materials with abrasive powder are used - they have high resistance to damage.

waterproofing of foundations with oklee insulation - technology of work execution

The first stage is the preparation of the foundation. It includes:

Careful alignment of the base - all the projections are cut, grooves are filled with a strong cement mortar.

Strain the seams with a sealant.

The surface of the foundation must be dry and clean. Immediately before the application of waterproofing, the surface is primed, a layer of lubricating waterproofing is applied and awaits its complete solidification.

If the material has a self-adhesive base, it is pressed firmly against the surface and rolled with a wide roller. On the horizontal surface, the waterproofing is stitched so as not to allow a large number of joints.

If it is necessary to glue the material on a vertical surface, then the insulation strips are pre-cut to the height of the foundation.

The overlap between the strips should be at least 10 millimeters. If it is necessary to lay several layers, each next layer is laid on the bottom seam, the center of the strip, adhering to the chess order. The joints must be treated with glue or mastic. The uppermost layer is also coated with a coating of waterproofing.

In the case where the roll materials are used, heating is necessary until the waterproofing is partially melted. This type of waterproofing differs from previous ones in that a layer of polyethylene or bitumen mastic is applied on its surface, which needs to be heated with a gas burner.

Most often this work is performed by two people, especially if you have to work on a vertical surface. The roll is placed by the underside on the surface, after which it is gradually heated, rolled out and pressed firmly against the substrate. If necessary, the edges of the web are additionally treated with bitumen.

Waterproofing materials that require the use of adhesives are mounted in a similar way, after applying glue to the substrate. The layers of waterproofing should be at least two, for reliable protection against moisture penetration. If the head of groundwater is more than 0.1 MPa, then at least three layers of insulation must be installed.

In order to provide additional protection against atmospheric moisture, waterproofing is sometimes done.

This is quite a labor-consuming and expensive construction, but in a number of cases it is necessary: on the perimeter of the building, the dust is poured over with rubble, after which the formwork is filled with a mandatory deviation from the wall. After the concrete has fully grasped, make a pasting waterproofing with roll materials. Over the insulation is laid ceramic tile or plaster made of high-quality cement.

Waterproofing of roofing

If the roof is to be insulated with expanded polystyrene, a film can be used as a waterproofing material, and it is not possible to install waterproofing at all, since expanded polystyrene itself is good against moisture if the seams are properly processed.

When you need to insulate and waterproof the flat roof, then it will be relevant to use a variety of membranes together with thermal insulation. One of the simplest options for flat roofing is the use of mastic (bulk waterproofing). This method can be used both for a new roof, and for sealing and sealing joints of an already operated structure. However, if you chose the roll-on waterproofing materials and plan to do their own installation, we recommend that you pay attention to the common roofing material, as well as to new materials - rubemast and eurorebroid.

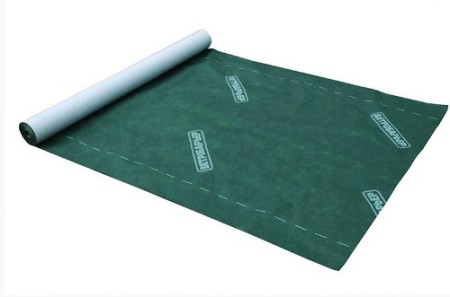

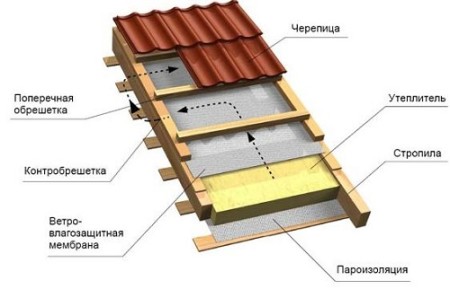

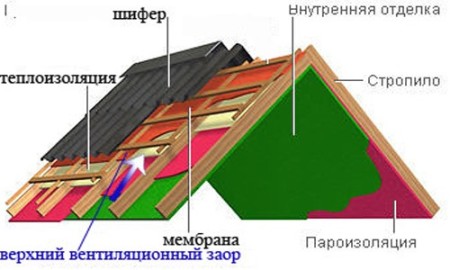

If the layout of the attic attic in the attic, then together with a heater and vapor barrier materials, you can use a superdiffuse membrane.

This is the best option, but very expensive. However, if the roof has a complex configuration, it is best to use a membrane.

Some experts say that if the slate is laid by all the rules, then there is no need for waterproofing. We will allow ourselves to disagree with them, and remind you that the roofing material was laid under the slate earlier. Now a hydro-barrier or waterproofing film with perforation is used. The same materials are laid and under metal.

The film is attached to rafters on a pitched roof, or to lags in the attic. For joining the building elements, the building fasteners are used. Fastening tools - nails or staples in stainless steel. If the attic is not insulated, then such a film, and even in combination with a heater - one of the most economical and quality options.

For metal roofs, it is recommended to use an anti-condensation film. When laying this waterproofing material, it is necessary to observe the upper and lower ventilation gap. To do this, a crate is installed. If a diaphragm is used, there is no need for a lower clearance.

For flanged roofs, there are special volumetric separation membranes for sale. As for slate roofs, then membranes are used and one ventilation gap is set up.

Finally I want to note that there are a lot of important nuances in choosing a waterproofing for the roof. But the most important depend on:

- Forms of the roof.

- The purpose of the roof (will be exploited or not).

- The kind of roofing material.

- Kind of insulation.