Pools for homesteads and suburban areas are becoming more accessible to the general public because:

-the expensive materials were replaced by cheaper ones;

- Modern designs of pools became easier;

-maintenance of swimming pools became available.

The owners of suburban areas often face the question: how to make a simple and inexpensive pool look beautiful, effective, fit into the landscape design of the site, while it was functional, reliable and easy to use? The answer is simple and obvious: you need to pay serious attention to finishing the pool. On the methods of materials and methods of finishing pools, we'll talk about this publication.

Content

Why you need a pool finish

At the stage of planning the pool in a suburban or cottage area it is necessary to carefully and fully consider all options for outdoor design, both the reservoir itself and the surrounding area. Decoration of the basin is done not only because it is beautiful and aesthetic.

Finishing materials are an important structural element that ensures durability and quality of attachment of the polypropylene pool bowl in the ground.

Below we will try to briefly review all the functions that the pool finish is doing. Let's start with the installation.

Polypropylene pool is installed in a previously excavated trench with flat walls and carefully compacted bottom. In this case, the exterior finish of the reservoir is something like a blind area. Thanks to it, the water from the bowl of the reservoir does not fall to the ground near the pool, it does not wash out or soften it. Thus, voids and deformations will not form in the ground, which can lead to damage to the pool capacity.

In addition, if there is a quality finish around the pool, there will be no dirt or water near the pond, which can lead to a traumatic situation. Near the pool you can sit comfortably with friends, take a walk, without fear of slipping and falling into the water. Not to mention to sunbathe on your pleasure on a flat and dry surface directly near the pond.

The surface finish around the pool is much easier to remove from debris - sweep, vacuum or just wash from a hose. And, of course, one of the main functions of the outdoor pool is aesthetic. Beautiful appearance is the first thing that catches your eye, and is the main criterion in choosing this or that finishing material. With the assortment that the modern market offers, the usual capacity can be tailored according to your preferences: to create a semblance of a tropical resort, a lake or a pond, you can make a copy of an expensive stationary pool lined with stone or small mosaic. The main thing is the right approach when choosing the finishing material.

Materials for finishing swimming pools. Features of installation work

a natural stone

In this case, most often use granite or marble, less often other types of stone, for example, sandstone. As for marble, pleasure is quite expensive, in addition, such a coating requires careful care. Regular cleaning agents for marble are not suitable. If you violate the rules of exploitation and care for marble, then the stone will eventually turn into a plaster and simply crumble. However, the pool, trimmed with marble, looks very impressive - marble has the property to reflect light unusually.

As for granite tiles, then there is something to choose from - the buyer is offered a variety of colors, shapes and shades. Granite tiles are rather unpretentious and well resists most cleaning products for swimming pools. If you choose a tile with a polished surface, use caution when swimming in the pool, as it is very slippery.

When laying granite or marble tiles, glue with adhesion of at least 1 MPa is used. On the surface of the tile it is applied with a notched trowel. To make the seams between the tiles smooth, plastic crosses are used. After the glue has fully grasped, the seams are sealed and rubbed. It uses a sealant and a special grout for swimming pools.

tile pool finishing

One of the most common decoration materials. It should be noted that the usual ceramic tiles for finishing the bathroom or kitchen for the pool is not suitable. Used special ceramics, baked at high temperatures. Such a tile has a high frost resistance, it is durable, absolutely not afraid of the impact of chemicals for swimming pools, and withstands quite high mechanical loads. By making a pool with ceramic tiles, you can create any design to your liking, create a panel or original mosaic, pattern or pattern.

To finish the bowl, tiles with a smooth glazed coating are used, which beautifully reflects the light. Steps and adjacent to the pool area are tiled with anti-slip coating.

There are ceramics and a few drawbacks: the pool tile itself is expensive enough, laying works also cost money and are spent a long time. In addition, the tiles in the outdoor pool can not withstand strong long-term frosts and crack.

During the operation of the pool, finished with ceramic tiles, it is necessary to monitor the tightness of the seams and, if necessary, to process the seams in a timely manner with a sealant.

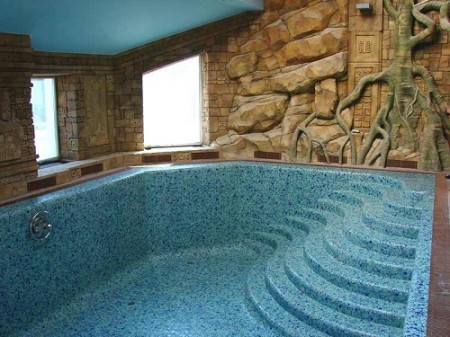

mosaic for the pool

In fact, this is also a ceramic tile, only a small one. The advantage of the mosaic is that with its help it is possible to trim complex relief surfaces. For decoration, mosaic of one color, but of different shades, is most often used. Thus, it turns out a very beautiful and refined finish.

Ceramic and smalt mosaic tiles are used for pool finishing. Smalta is a special colored glass. This is a very expensive material, therefore, as a rule, smalt mosaic is used only for finishing individual sections of the pool in order to achieve the desired refraction of light rays.

For laying the mosaic tiles used a reliable waterproof adhesive, which has an adhesion of at least 2.5 MPa. In order for the surface to be flawless, the beacons are pre-tensioned. If you want to make an ornament or pattern, the styling starts from the center to the brim. The solution rests on each part, after which it is pressed lightly against the surface, simultaneously tapping with a spatula or a rubber mallet. In order to somewhat simplify the work with small parts, the tile is first glued to a sheet of paper. After the glue dries, the paper needs to be moistened and scraped, after which the tiles are glued in the right place.

finishing of the pool with a film

Polyvinyl chloride film for finishing pools (PVC, liner, Alcorlan), can be corrugated and smooth. This is one of the easiest to install and inexpensive materials. It is very often used for finishing pools of polypropylene, which are placed inside the premises. Serves PVC film for about 20 years. This material is also used for finishing pools on the street, but in this case it is unlikely to last more than seven years.

To finish the cup use a shiny, reinforced film, having a thickness of about 1.5 millimeters, resistant to ultraviolet radiation. On its surface does not multiply fungus and mold, it is easy to clean the film from plaque. To clean the film coating, it is not possible to use products containing chlorine.

Care for accuracy and precision is required to finish the pool. In the process of finishing work, special tools and specific consumables are used. Therefore, finishing the pool with your own hands can cost you much more than the services of professionals.

Before laying the film, it is necessary to grind and clean the surface very carefully to prevent damage and punctures. Then the so-called fastening strip along the perimeter of the bowl is mounted. Film is attached to it. Next, a geotextile cushion is laid on top to protect the film from damage and condensation. The glue is not used during the assembly process, since the film is pressed against the walls under the weight of water. The edges of the film are connected with a special hair dryer, the seams are rubbed with liquid plastic. To fix the edges of the film near the nozzles, skimmer, drain pipe and other structural elements, use the fixing hardware, which is usually sold complete with a film.

pool basin painting

For all the cheapness and speed, this method is very impractical, since you will have to paint the cup every year.

rubber spraying of the pool bowl

It is used very rarely. The coating turns out to be rather fragile and short-lived, as the rubber is not reinforced, and it is very inconvenient to dispose of it.

pool of polypropylene

Applicable for both indoor and seasonal pools. The polypropylene sheets are joined together by an extruder. It turns out a solid and even coating. The appearance a little spoil the seams between the plates, and somehow hide them impossible. In addition, polypropylene coating will cost a little more than ceramic tiles.

decorative wood trim

Used relatively recently, but this version of decoration is rapidly gaining popularity.

Instead of a natural tree, the analog of semisynthetic is often used. This is a very practical material, it is distinguished by its high durability, rather democratic, in comparison with natural wood, cost.

With the help of a synthetic board you can quickly and beautifully equip the territory near the pool. This material does not rot, does not lose color, it is easy to mount it. If necessary, the board can also be easily dismantled. Board perfectly fit into any interior, and perfectly combined with other finishing materials.