It is also difficult to create a "own" bath, how to build a good house. Each bath room requires an individual approach. Traditional wooden materials can become not comfortable in the wash. To create the zone of the highest comfort, it is necessary to properly arrange the finish. Therefore, we recommend to join the Club of sauna lovers.

Content

Finishing of the bath inside

Initially, the bathhouse, as a room intended solely for the adoption of water and thermal procedures, looked modest: the wooden decoration of walls, ceiling and floor. In the lower steam room and dressing room were only necessary items.

However, over time, having tasted the charm of a bath rest, skillful hands began to transform the room. Today, the finishes of the baths are stylish and attractive, enriched by the possibilities of natural wood and fantasy solutions of designers.

How it is possible to make original furnish of a bath by own hands, using accessible materials?

Materials for finishing the bath inside

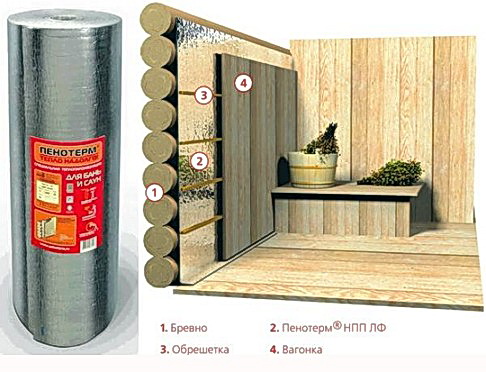

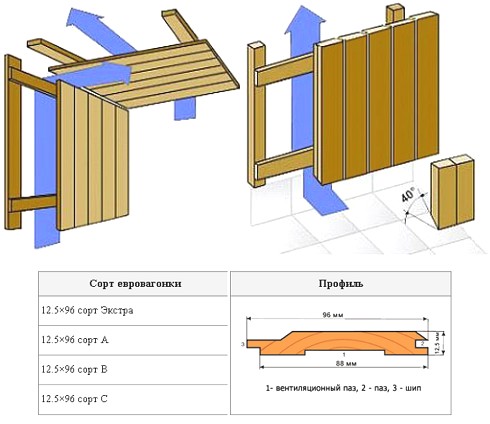

We will suggest that for the interior finishing of the bath use the lining of special lining and heaters. For decoration, we choose a lining made of hardwood that does not emit resinous substances, does not become hot and dries quickly.

This wood is cedar, linden, aspen and abasha. The selected material for interior finishing is ground, polished and impregnated with a special compound.

preparation of wood lining

There are two methods for processing wood:

• placing the material in a bioremedium ECOSEPT 46 BiO

• applying the solution in a traditional way using a brush, roller or spray gun.

When processing wood by immersion, prepare a working solution: the concentrate of ECOSEPT 46 BiO is diluted with water in a ratio of 1:20. The product is immersed in the prepared solution for 1 minute. With a large amount of material, batch processing is performed. The time of placing a package of material in the solution is 3 minutes. Then, the impregnated material is laid out to dry in well-ventilated areas.

When applying the solution using a roller or brush, the solution concentration is increased to a ratio of 1:15. Before the application of the material solution is additionally restored to the natural color of the wood. The application should create a uniform layer, excluding wetting or unprocessed gaps. Application of the bioremedium is carried out at a temperature not lower than +5 degrees. After complete drying (10-12 hours), the bale can be used for sheathing.

Bamboo from the manufacturer is delivered in raw form, so it is necessary to grind and surface brush.

For the plating and finishing inside the bath, the front side of the battens are grinded, rounded off sharp corners and brushed.

How to make a manual carving of the lining with oil, is shown here.

But in most cases, initially produce a heater installation, followed by plating the premises of the bath with a lining or a lining.

Design and decoration of bath rooms

domesticated dressing-room

Any bath, even small sizes, consists of several rooms. This is a dressing room, steam room and washing room.

In the dressing room, the peculiar role of the overtone, which sets the tone for a calm and measured rest. A tiny island, where you can relax from a hot steam room, began to turn into a solid peninsula of comfort and enjoyment.

In the waiting room began to appear comfortable chairs and couches, creating a zone of relaxation. The style of the room of the waiting room with the characteristic spiritual simplicity of the country turned the standard box into a bright and cozy room. There were stylized waiting rooms in the form of a house, ship and even an island with a view of the sea from the window.

Pine wood is traditionally used as the decoration of the waiting room.

Full environment of pine wood - a table and benches for a bath perfectly combined with a plasma on the wall.

humble thermae

If the design of the domesticated dressing room is the fruit of a designer's imagination, then the strict simplicity of the steam room remains the same modest. The tree of single and multi-level shelves and benches only enhances the calm and scorching atmosphere of the steam room.

In the bath, the finishing of the steam room with your own hands is simpler and more concise. The main thing is to keep enough space for the normal circulation of heated air. For finishing the steam room use mainly coniferous wood.

washing

It is necessary to strengthen the antiseptic properties of the finishing materials for the plating of the washing room. Therefore, the combined finish of the washing room is possible: lining and stone. The most common option for finishing the walls of the wash is the cladding with a variety of tiles.

Particular attention must be paid to the finish of the floor washing for any type: concrete, clay or collected from tiles. To ensure the outflow of water, it is recommended to cover the floor with ladders. Washing should be isolated from the steam room or fenced off by a partition.

Finishing the bath inside the lining by own hands

preparation of space for plating

Before the beginning of the plating, the baths produce cable laying and the installation of electrical appliances. The next stage is the laying of heat-insulating material and the creation of a lath for securing the skin.

As a heat-insulating material it is preferable to use an aluminum foil, the fastening of which is made using a stapler.

erection of a roof

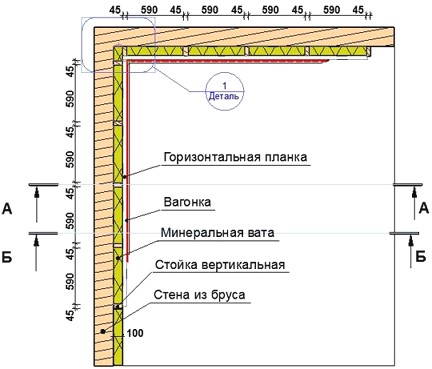

The rim is made from wooden bars with a section of 50x50 mm. The bars are attached to the wall by screws and dowels. The step of the battens is chosen depending on the width of the lining or lining (60 cm).

Before starting the creation of the lath, it is recommended that the bars be treated with an antiseptic preparation and covered with paint and varnish.

How to install lining and lining

decoration of the walls of the bath

Finishing of the bath with a lining starts with the hands of the walls. The stages of wall finishing will be the following:

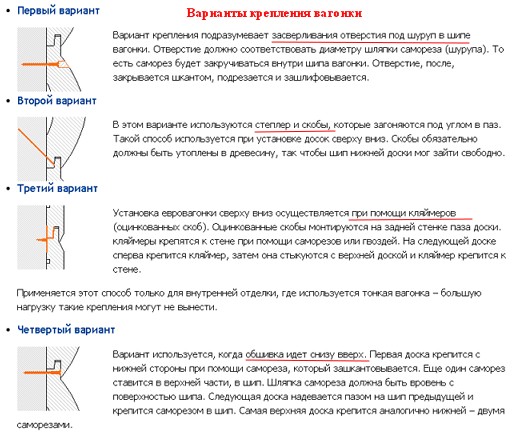

• installation of the first lining on the prepared lathing

• installation of subsequent lining

• Hardware installation.

Before walling, we measure the height and, in accordance with the size, trim the bale.

We fasten the fastening and fastening of the following elements to the clamp directly in the lock of the lining. The beginning of the skin starts from the corner of the room or from the heating device.

The wall panel is packed evenly on the walls, row by row, similar to the assembly of plastic panels. Preference for wall paneling with wood is given to the sliding fastening.

The last, installed in the row of lining, cut. The formation of slopes is made according to the principle of creating slopes from plastic.

How to make a wall covering, is presented in the video.

ceiling lining

For the ceiling, you can use a planed board thickness of up to 30 mm or a lining. The boards are fastened to the joists with the help of nails, chosen along the length of three times longer than edging boards. To create ventilation between the edges of the boards or lining, leave a small gap.

For example, the ceiling of a washing bath is sewn up by boards in the thickness of 5-6 sm with furnish by an aluminum foil with the subsequent warming. Let's tell, that the ceiling is warmed from the outside, having excluded hit of a moisture in the top part of a bathing premise.

For more information on the roofing, click here.