Its own bath, the oven, the design of which is designed independently - is the dream of many homeowners. Within the framework of this publication, we will consider the possibility of manufacturing a metal sauna stove on its own.

The metal furnace has a high efficiency compared to brick analogs, which, when heated, lose a lot of heat through the chimney.

Metal is a material very suitable for various types of processing - it can be forged, drilled, bent, boiled, cut, etc. The metal furnace is not subject to destruction due to long downtime, is not afraid of dampness, it can be moved and transported. Metal very well conducts heat, quickly gives it to the surrounding space.

Considering all of the above, it makes sense to consider a metal oven for a bath as one of the best options.

Content

- 1 Advantages of a metal furnace

- 2 Disadvantages of a bath furnace from metal

- 3 Metal for the furnace, how to choose

- 4 Choose the shape of the stove for the bath

- 5 Several options for self-made metal stoves for the bath

- 6 Bask furnace welding, step by step

- 7 Useful tips: is it worth it to make an oven with your own hands or buy a ready-made version, the life of a kiln made by one's own hands

Advantages of a metal furnace

- First of all, it is compact - this design can be installed without problems even in a small room.

- For a metal furnace, there is no need for a massive foundation - quite a simple lightweight base is quite enough.

- In a metal furnace it is easy to maintain a constant burning, and, accordingly, to keep the necessary temperature in the steam room.

- Saving money, the opportunity to make a stove with your own hands from improvised materials.

Disadvantages of a bath furnace from metal

Along with numerous advantages, the metal furnace has its disadvantages:

- The metal heats up very quickly, but it also cools down quickly.

- To maintain the temperature, it is necessary to constantly maintain combustion.

- A metal oven can not properly heat a large room.

- The need to protect the room from fire, the probability of which is quite high.

Metal for the furnace, how to choose

Choosing the metal for the sauna stove, you must choose, as they say, the "golden mean" - between the thickness of the sheet and the ability of the material to heat transfer.

Be sure to take into account the following factors:

The metal should be sufficiently heat resistant, and not burn out after several years of operation. Leading manufacturers of furnace equipment use heat-resistant steel 2 mm thick. For self-manufacturing, it is best to use a sheet of 4-4.5 mm.

Heat transfer. Thoroughly warming a sheet thickness of 8 mm is quite difficult - it will take several hours and a lot of fuel. It is not recommended to use black metal for making a sauna furnace, as this is not practical. This metal is able to withstand high temperatures without any consequences, but it is very poorly heated and has a low heat output. As mentioned above, manufacturers use high-temperature steel with a thickness of 2, a maximum of 3 mm. But since at home it will not be possible to weld a metal furnace, which corresponds to the factory characteristics and productivity, it is necessary to make blanks for a furnace of heat-resistant metal with a thickness of not less than 4 mm, especially if the stove is to be bricked.

Choose the shape of the stove for the bath

At first glance, the choice of the form for the stove is a secondary issue. This is fundamentally wrong - the shape of the heat source strongly affects its performance, ease of use and service life.

The sauna stove can be:

• Cylindrical.

• Horizontal.

• Figured.

• Rectangular.

It should be noted that it is the rectangular version that is the most popular, thanks to the convenience in use. The stove, which has a rectangular shape, has so-called corner zones, which are very weakly heated. This means that if one element of the furnace is maximally heated, then the other (corner zone) cools down. Thus, a good balance of heat flows is ensured, and the room is evenly warmed up.

Uniform heating of the structure directly affects its mechanical stability. Thus, a metal furnace, having a circular or cylindrical shape, does not withstand heating, and therefore for such furnaces it is necessary to select steel thicker than 5 mm.

Several options for self-made metal stoves for the bath

Today it will not be difficult to find any drawings of metal furnaces for a bath in the network - since they have been used for a long time, today there are many variants of designs. The simplest and most primitive is an oven made of an iron barrel.

In the process of making a cut off the bottom of the vessel and the lid - a cylinder is obtained. It is about half loaded with brick. Bricks are placed on the edge, the grate is mounted from above.

The remaining free space is filled with stone. Then it remains only to mount the chimney and install the lid on the oven. Such an assembly is very easy to make, but it is extremely inconvenient to use.

If the bath is small, it is best to make a compact stove-heater made of heat-resistant sheet steel. In this case, the inner surface of the stove is laid out of refractory bricks. The furnace itself needs to be put in half a brick, the chimney - a quarter. It is not very difficult to make such a stove, it is quite convenient to use, requires a little fuel, evenly heats the room in a short time.

Bask furnace welding, step by step

It does not matter which option you choose for your bath, in any case you need tools, supplies:

• Sheet steel thickness 4.5-5 mm.

• Steel rod 10-15 mm thick.

• Grate.

• Door for firebox and ash, latch.

• Tap water.

• Steel pipe 2 meters in length. The thickness of the walls is from 10 mm, the diameter is 50-60 cm.

90 cm of pipe will be used for the manufacture of firebox, 60 cm for a water tank, 50 cm for the manufacture of other minor elements. Doors for the furnace and ash-tray can be made by yourself. Of the tools will definitely need a Bulgarian and a welding machine, electrodes "deuce" or "troika", roulette, chalk.

Below, we will consider several options for making a metal stove for a bath with your own hands:

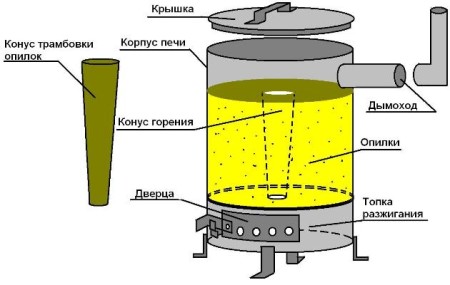

stove with a closed stove

In an aggregate of this type, as the name implies, a closed type of heater is used, therefore, in order to "give a pair", it is necessary to open the door.

The algorithm for manufacturing the unit is as follows:

Cut off from a metal pipe 90 cm, cut through the resulting piece of aperture for an ash-pit. The size of the opening should be approximately 5x20 cm. On the side of the opening on the inner surface of the pipe, it is necessary to weld the support posts for the grate. Any metal plate or corner can be used.

Now we turn to the furnishing of the furnace: a hole is cut about 25x20 cm in the pipe, the fasteners on which the heater rods will rest are welded on top. For this purpose, a steel rod with a thickness of 1 cm is suitable. It is possible to use as a support a ready-made grate for round furnaces, which can be bought in building materials stores.

On the opposite side of the heater, a hole is cut through which steam will be fed.

Next, the stove should be filled with a stone that is suitable for this type of furnace design - soapstone, diabase, or at least a round river stone. It is forbidden to use granite and rocks containing mica.

Talcochlorite:

Black diabase:

Separately, it is necessary to mention amateurs collecting stones on railway embankments. Granite itself is harmful when used in a bath, and railway embankments are periodically treated with chemicals against weeds. And if you also remember, by what principle toilets work on domestic railways, the whole "benefit" of using stones from the embankment becomes obvious. In the matter of choosing a stone, it is better not to engage in amateur activities and not to pick up the first cobblestones that have fallen in. You can just buy a rock of a suitable breed - for example, packing a volcanic basalt weighing 20 kg will cost about 500 rubles - for a small stove this is more than enough.

Another necessary element of the stove heater is a tank for heating water. To make it, take a piece of pre-prepared pipe length of 60 cm. We weld the water supply tap. A metal platinum of suitable size can be used as a cover. We cut it into two equal parts. In one half a hole is cut for the chimney, then it is welded to the tank. The second half can be removable or fixed to the tank with the help of loops.

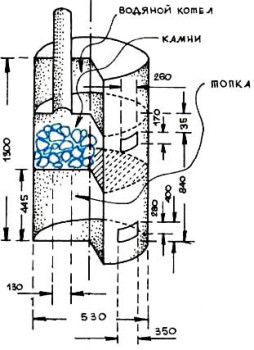

open-hearth stove

Based on the design of this unit, you can take a metal pipe, which is divided into two parts by grates. In this case, the upper compartment - actually, the furnace, and the lower serves as an ash pit and ash collector. Both compartments must be provided with tightly closing doors.

The upper part of the pipe is brewed, there is also installed a chimney branch about 10 cm in diameter. A box - a container for stones - is also welded to the upper part. The knee of the chimney must be made curved - this allows you to achieve a higher temperature of heating the stones.

The stove with an open stove can also be made in the form of a parallelepiped. In this case, not a pipe is required, but blanks of sheet heat-resistant metal 4-4.5 mm thick.

A stove of this form must necessarily be equipped with a hot water tank. For the right rectangular shape of the stove options with the device of the hot water tank is very much: you can mount the tank on either side, weld the pipes inside the stove, make a water jacket on the two sides of the casing, and so on. One of the most convenient options is to make a water tank directly on the chimney pipe.

You can realize this idea both independently and buy a ready tank in the store.

In the second case, the tank cuts into the chimney, namely into its vertical part directly above the stove, then two pipes are connected: the cold supply and the selection of hot water. If the tank is large enough, it can act as a water reservoir or simply a heat exchanger connected to the main water tank.

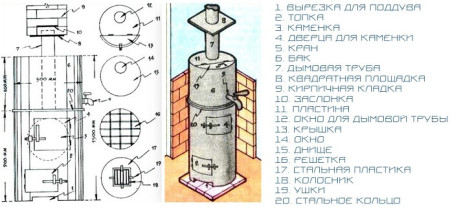

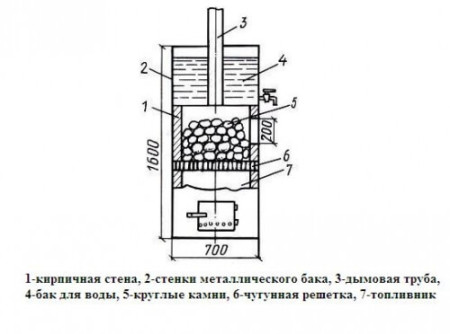

metal oven for a bath with additional brick walls

This version of the metal stove is quite complicated, and time-consuming efforts are justified - such a stove very well accumulates heat. The design is a metal casing, inside which is laid brickwork.

For such a stove, a sheet of 2 mm thick is suitable, since the metal will be strongly heated, and consequently will not burn out. For internal brickwork, a refractory chamotte brick and mortar are needed. A simple cement-sand mixture is not suitable, and if there is no experience in this kind of work, it is better to purchase a ready-made dry mix for stove laying. The solution is kneaded according to the instructions on the package.

Manufacturing technology is as follows:

First of all, prepare the metal base of the stove, to which the legs are welded for stability. On the base lay the first row of solid bricks.

Further, the brick is laid like this: near the furnace in polkirpicha, near the chimney in a quarter. After the cavity is ready for the ash-bluff, a grate is installed, after which it continues to work.

For apertures of an ashtray and a furnace, metal corners, approximately 20x20 mm in size, on which bricks are laid, will be needed. Above the furnace are installed a grid of rods or reinforcement, on which stones will be later laid. As soon as the masonry goes to the level of the stove, a small opening is left on the side, into which stones are poured and water is poured during bath procedures.

Chimney channel is better to do not straight, but winding - this will ensure better heating of the stove body and complete combustion of fuel. After the brickwork is completed, the solution must be allowed to dry properly.

Then you can start welding work. In this case, the body of the stove is a kind of case, which is worn on top of a brick "box". In the process of welding, the box will be superfluous to strengthen the seams with a metal corner - this will simplify the work and make the seam hermetically sealed. Preparing the material for the front wall of the stove, you must immediately cut out the apertures for the ash-pit and the furnace. Details for future doors do about 1 cm more on each side than the opening. This is necessary to ensure a tight fit to the body of the stove. You can also additionally seal the doors with an asbestos cord.

In the side wall, we also do not forget to make an opening opposite the "window" made in the masonry, to allow steam to enter the room. Next, for the opening, you need to make a door. It is desirable that it opens down, and is equipped with a "cold" handle, best of all wooden. On the workpiece for the furnace cover, a hole for the chimney is pre-cut, after which the lid is welded into place. After this, a chimney is installed and welded. Now it remains only to install the metal "cover" in place, and load the furnace with stones.

Useful tips: is it worth it to make an oven with your own hands or buy a ready-made version, the life of a kiln made by one's own hands

Today, most owners of their own country houses want to have a modest, small, but their own bathhouse, or even a sauna with a swimming pool on their site. What source of heat to choose - "self-made", or ready, factory-made? Here it should be noted that two seemingly identical structures, one of which is made independently and the other at the factory, can work in the same conditions in different ways.

For example, factory stoves for a bath, as a rule, are of higher quality and have many additional functions. For example, in addition to the fact that such an oven heats the steam room and heats the water, it can still heat the dressing room.

A homemade stove can hardly shine with such functions, but here one should not forget about one of the main reasons, because of which, in fact, the stoves do by their own hands - a trivial lack of finance. The self-made unit is much cheaper than the purchased analog. However, it should be recognized that in some cases handicrafts do not meet the elementary requirements of fire safety, and it is frankly dangerous to exploit them. Although, of course, there are nugget masters who are able to make the stove as good as the factory, it is still recommended to buy such things from trusted manufacturers in specialized stores.