Plastic paving slabs are a relatively new material. It is impossible to speak about their positive qualities or disadvantages - the term garden paths made of plastic means several materials having completely different structures and manufactured from different raw materials.

Content

- 1 Which garden paths to choose

- 2 How to lay a trellised tile

- 3 Benefits

- 4 Tiles made of plastic and sand, so-called. polymeric tile, its features

- 5 Advantages and disadvantages

- 6 Features

- 7 A path for a summer residence from plastic - we execute a laying

- 7.1 preparatory work

- 7.2 tiling

- 8 Plastic grass traces

Which garden paths to choose

The most important selection criteria are the owner's preferences and the conditions in which the tracks are planned, because each of its species is distinguished by the ability to resist the effects of moisture and strength characteristics. As for the price policy, the cheapest ones are lawn grills. In shape, these are squares with a side of 30 or 50 cm, a thickness of the order of 2 cm, weighing 1.5 kg. Tiles have on their surface through symmetrically located slots. On the sides of the tiles there are grooves that allow the engagement of the planes.

How to lay a trellised tile

Laying trellised tiles is done quickly, on any leveled surface. The installation process is as easy as assembling a children's designer. The only, but necessary to fulfill the condition is the presence of a flat surface for styling - otherwise the fragments will be permanently disconnected when the load is applied to them. In the slots available in the tiles, grass can germinate, which is not provided by any of the existing coatings.

Assembling tracks on the principle of the designer allows you to create various geometric shapes. Places of joints with curbs, objects of garden decoration, lawns are filled with special corners, flaps, expanders. Obtained on the track surface allows you to get a good grip of the foot with the blade, which excludes the possibility of injury on a slippery surface during rain.

Benefits

Latticed garden paths made of plastic, the price of which is fully accessible to every owner of the suburban area, have the following advantages:

- they are not prone to deformations and changes in shape, can withstand severe static loads,

- water on such paths does not accumulate, during operation they do not create problems with accumulated water, dampness, mold,

- wash or clean from dirt, plastic surfaces are very easy, chemical fluids that get on them absorb material is not inclined, i.e. fertilize the grass, sprouting through the lattice, you can,

- plastic is not prone to rot in damp conditions, so its aesthetic appearance persists for a long time,

- to master the process of installing the tracks is not difficult, you can do the stacking very quickly,

- the decision to perform the installation yourself will save money.

The practical benefit of trellised paths in the suburban area is also in getting rid of dirt during rains - if the paths are laid out with such a tile, then it will not be applied to the house. There are no special requirements for the care of plastic material. It can be washed with running water a couple of times a week - this will be enough to maintain cleanliness.

Of course, such a path can hardly be attributed to solid structures, and the producers of the material also did not take care of the availability of a rich color range.

Tiles made of plastic and sand, so-called. polymeric tile, its features

The second type of tile, consisting of a mixture of plastic and sand has a smaller area, in appearance it is very similar to paving stones. The material is quite heavy, its colors are diverse. The composition of the tile includes:

- plastic mass,

- river sand,

- pigmentary dyes.

- composite elements.

The cost of polymer tiles is much higher than the lattice, installing it - a matter of painstaking and long-lasting. Serves such material for a long time.

Advantages and disadvantages

Among the quality characteristics of the tiles should be noted:

- weight, almost two times smaller than that of pavers,

- the strength provided by expensive binders, it is their presence that causes the high cost of the material to cover the tracks,

- waterproofness providing durability of a material, service life - about 50 years,

- the material itself and the rippled surface inherent in many types of tiles completely eliminate the sliding effect, even over the wetted surface of the material,

- to store and operate the tile can be in any climatic conditions - it is not afraid of heat or cold, snow or rain.

Before deciding to build plastic tracks, even high-quality empty ones should be found out that:

- plastic still has far from stone resistance to the impact of aggressive chemicals;

- under the influence of ultraviolet radiation, the tiles will eventually change the shade, i.e. burn out;

- the choice of tiles in terms of color and texture of the surface is somewhat poorer than that of sand-cement materials;

- the process of abrasion of the path for dacha from plastic will occur faster than if natural pavement paving stones were used.

Features

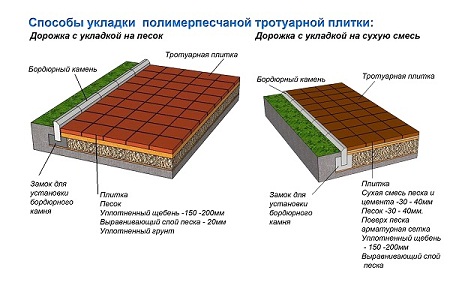

Possessing relative ease requires a thorough installation - experts recommend that the masonry of the tile is applied to the cement slurry, i.e. creating an all-in-one connection. Installation of ordinary cement tiles can be performed on well-compacted river sand.

Although the tile has water-repellent properties, the tracks still have to be equipped with a drainage system, however, it is not difficult to do this - usually on both sides of the path, hidden drainage grooves are made.

A path for a summer residence from plastic - we execute a laying

Although the progress of construction work on laying plastic material is approximately the same as the laying of pavers or ordinary tiles, but some features are still there.

preparatory work

First, mark the track. First, mark straight sections, at turning points or in places where the width of the track can be changed with a cord and pegs, carefully marking the lines that limit it. To simplify the work, it is desirable to plan the width of the track to a multiple of the size of the tiles - in this case you will have to cut the minimum number of fragments.

At the second stage, it will be necessary to dig a shallow ditch in accordance with the marked outlines. Depth, depending on the quality of the soil, can be from 30 to 40 cm. It is not necessary to achieve an ideal evenness of the walls and the bottom of the moat, but it is absolutely necessary to remove all the rootlets and remains of the plant roots on the bottom, otherwise there is a risk that sooner or later they will begin to germinate and threaten the integrity of the path. If the vegetation on the site is very dense - it is better not to take risks, but to treat the dug out with a pesticide. To handle chemical substances should be followed all the precautions, we must not forget that they are highly toxic to humans. On both sides of the track, drain pipes should be laid. With a track width of up to 100 cm, the slope of the finish surface is not necessary.

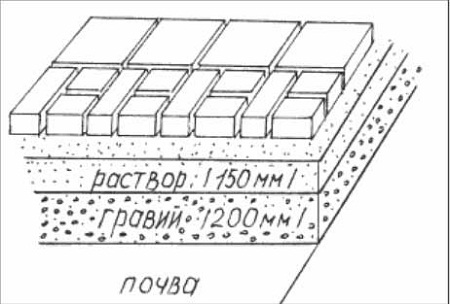

Laying the foundation of the track will require backfilling and tamping:

- 15 cm of gravel,

- 5-7 cm of a layer of pure river sand.

The surface of the gravel, then the sand is leveled horizontally - the screed base must be flat and horizontal. For its implementation, use a cement-sand mortar, prepared according to the usual recipe. The amount of solution is calculated on a three centimeter layer. To harden the solution in warm dry weather it will take a couple of days. Before carrying out any further work, you should wait for the full hardening of the screed - if the work continues too soon there is a threat that the surface will fall under the weight of a person.

Fill with a solution of the curbs of the ditch should not be - they should just be covered with sand.

tiling

It is not difficult to implement the laying of a garden plastic path by oneself, but it is still necessary to listen to the recommendations of specialists. The first rows are laid on the cord, as flat as possible, checking each tile level. A high-quality screed involves the use of a minimal layer of mortar, if only it would allow aligning the stacked elements. If there is any doubt as to the laying of the first rows - it is better to remove the tiles before solidification and repeat the process with more accuracy.

You can install each element by tapping it with a rubber mallet.

First of all, entire fragments are laid along the entire length of the track, Then they are laying corners and frames. For sawing plastic tiles, a hacksaw is used - electrical tools, for example - a Bulgarian, leave a thermal trace on the surface of the polymer material.

At the final stage, along the edges of the canvas, curbs are laid for a couple of centimeters higher than the height of the canvas itself. The space remaining between the whole tiles and the border is laid in side-by-side. When carrying out the work, it should be ensured that the frames are horizontal. The joints can be sealed with liquid glass, cement mortar and other moisture-resistant compounds. The seams are rubbed into several receptacles, leaving no voids is impossible.

Start the operation of the track by making sure that the solution has completely hardened - in 2-3 days. At this time, you should install warning signs near the track - because the view of the track will be such that it is quite willing to go through visiting neighbors. It is much more difficult to repair a previously unused coating than to lay it down.

Plastic grass traces

This kind of plastic tile allows you to organize effective protection of the house from dirt or moisture. Naturally, its use will simplify cleaning in the house and help keep it clean even in bad weather.

It is easy to guess that the Travka path is due to its name by the presence on its surface of plastic bristles resembling grass. For the production of tracks using PVC, which allows them to operate inside the house and on the street. The range of temperatures at which the grass can be used is from +70 C to -40 C. The dense surface of the tracks does not slip, it is resistant to the influence of an aggressive environment, there are no special rules for grooming.

By design, the track is a connected segment of 50x15 cm, without a substrate. Equipped with its drainage system (located in the lower part of the sewage channels), it is possible to obtain an even distribution of the accumulating moisture over the entire area of the coating.

Regarding the advantages of the modular material system, they are undeniable - in case of need, you can quickly change any of the track fragments, in addition, the installation of the coating is very simple. If desired, you can use the Grass tiles in different colors, creating beautiful colored mats or paths. The variety of colors in which the coating is produced makes it easy to choose the right shade. Using the Tray The grass to cover the steps will completely eliminate the possibility of slipping in wet weather. The issue of the material is produced by domestic and foreign enterprises.