It is known that novelties of materials in the construction industry are met with distrust. But only not tested by time technologically perfect recipes. Insulating foam glass is able to meet strict requirements. Simplicity of installation and unique technical characteristics of foam glass make it clear that we are dealing with a solid material.

Content

Is it easy to be first in a hundred years?

"Frozen" in the merciless 30-ies of the XX century for a number of reasons, the initiative of Soviet researchers for the production of foam glass was intercepted in the 40s by American glass magnates. As a result of the coincidence of interests (otherwise it could not have happened), PPG and Corning Glass Work became a joint production association.

Already in 1946 the first concrete slabs, equipped with an interlayer of foam glass, were successfully used in construction. Today Trademark and Foam Glass foamglas it is a leading manufacturer with a worldwide reputation. A successful experience in the use of foam glass has been universally recognized. Returning to its historical homeland in 100 years, foamed glass has shown to its compatriots an excellent thermal insulation for walls, roofing, partitions for almost all types of buildings and structures.

The simplified scheme and possibilities of application are explained by the ease of binding of the material to concrete, stone, cement, reinforced concrete and ceramics. So is it easy to be the first and the best?

What is foam glass?

Foam glass or foamed and cellular glass is a glass mass with a characteristic gas-filled closed porosity.

To produce the material, the ability of the silicate to soften and swell at a high temperature (1000 ° C) is used. When the necessary viscosity coefficient is reached and the cooling is gradually cooled, the foam mass acquires an excellent mechanical strength.

plates and blocks

The industry produces foamed glass in the form of blocks with a width of 125-600 mm, a length of 125-1200 mm, and a thickness of 20-120 mm, and also pl.

The main parameters of blocks of foam glass are:

• The foam glass density in the products is 110-180 kg / m3.

• thermal conductivity from 0.045 to 0.050 W / (m • K)

• vapor permeability up to 0.005 mg / (m.p. Pa)

• water absorption -2% of the initial volume

• sound attenuation - 56 dB

• Operating temperature range: - 200 ° C to + 500 ° C.

We add that the time of operation of products from foam glass is not limited.

The industry produces varietal plates and blocks, as well as plastered, teplogidroizolyatsionnoe (okleennoe), soundproof and shaped foam glass.

foam glass granulated

But the special interest is caused by the granular foam glass, which is used as a reusable heat insulation of the backfilling. The laid granulate of foam glass reduces the load on the foundation and the floor. This quality makes it possible to use granular foam glass for superstructures of upper floors, heat-insulating floors.

As a filler filler designs of lightweight panels, granulate is an ideal option. I filled the material from the manual packaging into a special frame cavity and that's it! Non-moving moving granules perfectly fill any voids of a complex configuration. In the foam glass granules there are no foreign impurities or fibers, there is no specific odor, the material does not leak and does not require additional sealing.

And, finally, this material is effective for cases when the use of other heaters is inefficient or technically difficult.

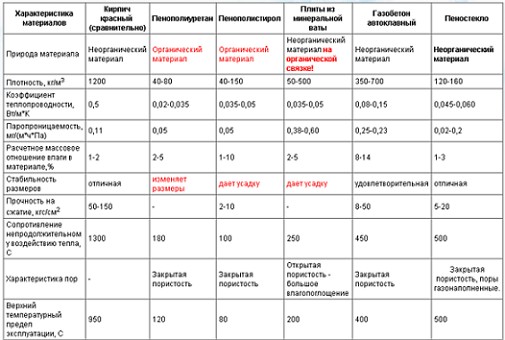

To verify the superiority of foam glass insulation, it is recommended to make a comparative characteristic of the parameters.

Technical characteristics of foam glass

A simple analytical analysis of the technical properties and characteristics of the novelty and other known heaters shows the advantages of foam glass. This high thermal insulation properties, non-shrinkage, strength and low density, the ability of the material to maintain positive qualities for a long time.

In addition, the resistance of the material to aggressive environments and vapors is amazing. It is easy to see that this combination of beneficial characteristics is no longer available in existing heaters. Thus, the conclusion arises in the obviousness of the advantages expressed in the universality and practicality of foam glass. The only thing that confuses with all the positive qualities, is the essential price of foam glass.

Areas of use

Blocks and panels of foam glass are successfully used for the following activities:

• thermal insulation of roofs: flat, with corrugated board, pitched roof

• for insulation of socles, foundations and foundations

• insulation under the panels inside and outside the premises

• for the warming of structures with high humidity

• for soundproofing of walls and partitions

• for thermal insulation of decks and slabs of concrete roads

• for insulation of pipelines of any purpose.

Recall that foam glass, because of its environmental and hygienic safety, is the only material that meets sanitary and fire-fighting performance. Therefore, it is not recommended to insulate from inside your own house or apartment glass wool and especially foam.

How to insulate with foam glass

The technology of insulation with foam glass is similar to any plate installation. To fix plates or blocks for internal or external fastening, arrange a bond and select the glue. This is the installation of anchor or special metal L-shaped staples. How should I install foam glass?

Plates and panels of foam glass have good installation properties. Foamglass is easy to handle with simple cutting tools, it is easy to drill and nail or glue. Thanks to the porous structure of the outer surface of the foam glass, it is easy to glue it with a special mastic and to produce external plastering combined with astringent aluminosilicates.

primer and adhesive for work

Primer for the subsequent installation of insulation is a mixture of resin with a base that is resistant to saponification. The primer layer blocks the appearance on the working surface of oily streaks that make up the plaster.

The application of the primer to the surface is carried out in a traditional way using a roller.

FOAMGLAS® glue is a ready-made solution of a cold two-component composition (component A-modified bitumen and component B-powder for preparation of a glue solution). The glue is applied to slabs or blocks with a notched trowel on the entire surface and from the sides. Consumption of glue with point bonding is 2.5 kg / m 2; at continuous - up to 4,5 kg / sq. m. Then blocks or plates are installed at the place of installation and mechanically fixed.

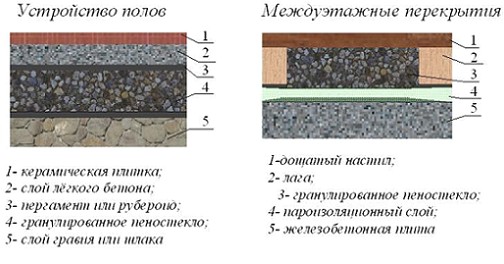

floor insulation

The use of blocks for floor insulation is possible for plinths located above the 0.00 mark and directly in the ground.

When laying the bottom surface of the blocks are protected with waterproof plaster, and the lower corners of the foamed glass layer are protected with a corner. The supporting part is made over the leveling screed. The use of floor slabs eliminates subsidence and deformation of the substrate.

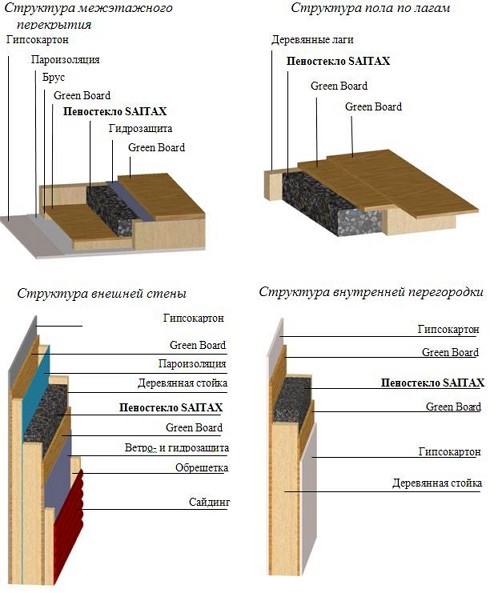

application of granulated foam glass in the interstitial floors

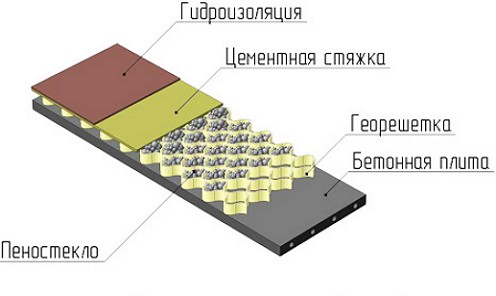

For insulation and noise insulation in the interfloor overlapping and roofing for the fixation of the material, geogrids are used, the cells of which are covered with granules, and then the entire structure is filled with concrete milk.

wall warming

The insulation of the external and internal walls of foamed glass is laid directly on the surface using a glue solution and mechanically fixed.

After gluing all the panels, the adhesive that has come out is removed and the surface is rubbed.

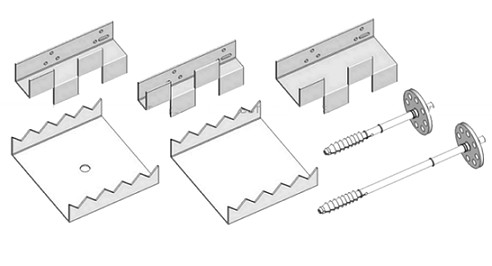

fixing toothed plates and anchors

When the walls are insulated with foam glass for its attachment to the bearing part, the toothed fixing plates are used.

Steel toothed plates 1.5 mm thick are installed along the marked wall of the wall through a layer of insulation.

The height of the teeth reaches 30 mm and has a sawtooth configuration. In the center of the plate there is a landing hole of standard diameter (10, 12.14 mm) for fastening the dowel with a nail.

anchors

Anchors are designed for the hidden type of fixing foam glass to the wall surface and floors. Typical sizes of the anchor are used for walls of different thicknesses. Fastening of the steel anchor is standard.

roof insulation

When laying foam glass on the roof, the prepared adhesive solution is smeared over the surface using a toothed squeegee. The thickness of the solution layer should be 5 cm.

Then, glue is applied to the sides of the body-insulation blocks and laid on the prepared surface, tightly pressing against previously laid blocks. After stacking of foam glass, the roofing is laid using the fusing method.

Thus, the construction has acquired a universal insulation, which has excellent performance characteristics and no less attractive simple installation method.