The usual concrete base is unlikely to be a worthy decoration of the facade of a residential building, rather, it will look like an unfinished element of construction work. There are quite a lot of ways to decorate the plinth, one of them is decoration under the stone. Facing the socle not only protects it from the harmful effects of the environment, but also gives the cap a finished look. The facing material for the base must meet all the requirements for strength, resistance to temperature changes and hydrophobicity. The design of the cladding system is pre-selected depending on the humidity level, the average temperature in the region, etc. There are several ways to finish the cap under the stone:

- Decorative plaster

- Decorating with natural or artificial stone.

- Decorating with decorative panels or "siding for socle"

The latter method will be considered below.

Content

What are decorative panels for the plinth, the scope, advantages and disadvantages

The concept of "socle siding" exists only in Russia. There was this finishing material in Canada and the USA under the name "panel for brick and stone." In Russia, also known as "socle-facade panels", but in all cases it is about the same material. The cost of siding for the socle is much higher than that of an ordinary vinyl, so in Russia it is mainly used only for finishing the base and the socle - for the sake of economy. Walls of houses are finished with usual vinyl siding.

The modern market of building materials offers a very wide selection of decorative panels for the basement for brick and stone. Models differ in color, size and texture.

use of socle siding

Decorative panels for the socle are used in several directions:

- Directly for facing the basement of the building. This cladding is quite strong, well tolerates mechanical influences and high temperature changes, especially in the cold season, when a large amount of snow accumulates beneath the foundation.

- For a mixed facing of the facade of the building in conjunction with conventional vinyl siding. This combination gives the design of the house a unique appearance and looks very attractive.

- For full facade of the house. Such decoration is very expensive, but as a result, you get a real architectural masterpiece.

The material for the production of decorative panels is vinyl. In addition, the composition includes a whole list of special additives that give the material plasticity. Over the life of the decorative panels do not need additional care and protection

There are many varieties of decorative panels for the plinth. They all imitate various materials: shingles, bricks, wood, stone, etc. It is not every specialist who can distinguish natural material from synthetics.

decorative panels for socle: advantages and disadvantages

The main advantages of this material are attractive appearance and good technical and operational characteristics. In the production of socle siding, modern polymer compositions are used, so that the material can last up to 50 years and more. In addition, as mentioned above, throughout the life of the material, the material is practically maintenance-free.

Decorative panels for the base of the house are able to withstand even the most aggressive environmental impact, which is especially important, given that the socle siding is located in close proximity to the ground. More specifically, the material can withstand the differential from -50 to +50 degrees Celsius without any consequences. And even with cooling to the maximum level, the material is able to withstand mechanical damage. The material is absolutely impervious to the effects of microorganisms, mold and fungi. Decorative panels do not rot, they are not susceptible to corrosion. The basement does not fade under the influence of direct sunlight. For the installation of decorative panels there is no need for special knowledge and skills, it is quite possible to manage on their own, without paying for the services of professionals. An important advantage is the democratic price of the material, which, although somewhat higher than for conventional siding, but still available to most developers.

There are some drawbacks to this material. For example, despite the fact that the material has a wide color range, and a wide variety of textures, the material of certain colors, textures and size will have to be ordered individually. But this is, rather, a feature of this product, not a flaw. But the really serious flaws can be attributed to the excellent combustibility of the material. If the building burns, the siding melts almost instantly, although it burns badly, does not emit toxic substances, and can even create a barrier to spreading flames. That is why fire safety rules prohibit the installation of decorative panels in shops, public enterprises and warehouses with combustible materials. But since science is not on the spot, in the near future, if this material does not lose its popularity, all the shortcomings, we hope, will be eliminated.

As for the price of plastic panels for stone, it depends on the specific manufacturer, and the technologies used in the production of material. The cost per square meter of material can range from 400 to 2000 rubles and above.

General rules for installing decorative panels on the plinth

- The panels are mounted on the plinth from the right to the left.

- When mounting the material, consider its thermal expansion, leave small gaps - do not tighten the screws until they stop, leave a gap between the self-tapping screw and the panel a few millimeters. The same applies to the gaps between the panels themselves. If the gaps do not leave, the panels may deform under the influence of ultraviolet.

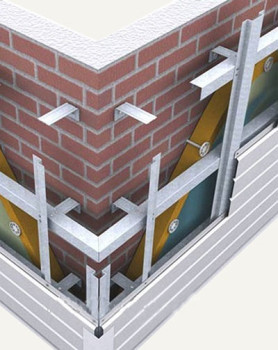

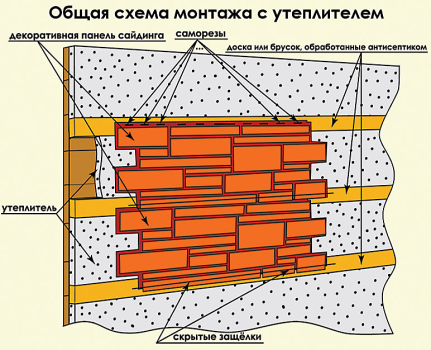

- Installation of decorative panels must be done only on a pre-installed crate of wooden bars or galvanized profile.

- Self-tapping screws should be screwed into the base to a depth of at least 11 millimeters.

- For additional insulation under the siding lay "breathable" materials. Do not use an insulating material that contains foil.

- Each element must be mounted with screws in approximately the middle.

- To calculate the required amount of material, you need to divide the width of the socle into the length of the decorative panel, summarizing the results.

Preparatory work

As we already mentioned above, one of the mandatory stages of the preparatory work is the preparation of the laths under the plinth plastic panels. Some builders manage to mount the siding directly on the stone, concrete or brick, referring to the fact that the crate is short-lived. We will not consider this option, since it is inconvenient to fasten the panels directly to the base, and it is unlikely to be able to get an even surface.

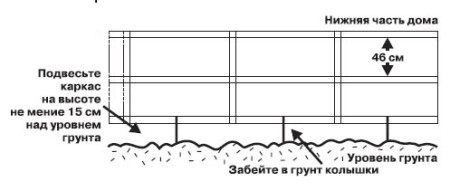

For the battens a wooden beam of 3x4 cm is suitable. The timber must be impregnated with the composition from decay and antiseptic. These chemicals are cheap. But if the groundwater is lying close to the surface on the site, or there are frequent precipitations in the region, and the soil is constantly wet, wooden bars should be avoided and replaced with a galvanized profile. The metal profile will last several times longer in such conditions. In addition, the height of the crate should be selected, focusing on the climatic conditions of the terrain. For example, if the soil freezes in winter to a significant depth, then the distance from the bottom of the crate to the ground should be at least 150 mm. If the soil does not freeze in winter, the lath can be fastened directly above the surface.

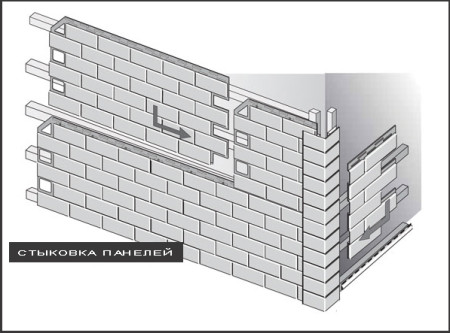

Reins can be fastened both horizontally and vertically, but the first option is more convenient for the lining of the base. The distance between the slats should not be more than 45 centimeters with the horizontal position, and 90 centimeters with the vertical. For the pile foundation the crate hanging from the facade is installed.

For decorative panels having a width of 460-480 mm, the bars of the battens are fastened in three lines - below, in the middle and at the top, at the level of the last fastener. The bars are attached to the plinth by screws. The dowel under the screw must have a length of 70-100 mm.

Installation of decorative panels

You need the following tools to work:

- Screwdriver or electric drill.

- Screwdriver.

- Bulgarian.

- Hacksaw for metal.

- Punch.

- Level of construction, water level.

To begin with, you need to prepare all the necessary elements: finishing strips, corners, "complex corner" elements, etc. - that everything was at hand.

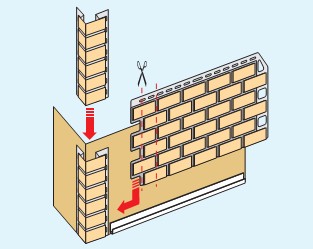

The starting strip is installed at the base of the socle, fixed with self-tapping steps of 300 mm. To it the profile lath is fastened. Then the corner bar is fixed.

If necessary, it is adjusted in height to the required length and fixed with screws to the crate. The allowance of the angled bar on the support bar must be at least 10 mm. In work it is recommended to use the element "complex angle", which will greatly simplify the docking of the panels among themselves.

The first panel is inserted by the lower crest into the groove of the starting plate. It is not necessary to push it to the stop, it is necessary to leave a gap for deformation of the order of 3 mm. The panel is fixed with a screwdriver or electric drill with adjustable revolutions, galvanized screws with a wide bonnet through mounting holes.

Then you can proceed to install the next panel. First, it is wound in the support bar, then gently moves to the first panel. The element is fixed in a similar way. All other decorative panels are mounted on the base in the same way.

The last element of the lining, if necessary, is cut to the desired size. From this element, the facing of the next wall begins. The upper fastening edge is closed by the finishing strip. It plays the role of an element of decor, and, if necessary, a transition element for mounting the upper facade panels.

Each decorative panel must be fastened in at least five places. The panel should be installed to the surface strictly at an angle of 90 degrees. Under the influence of ultraviolet the plinth panel under the stone can expand and contract by almost 6 millimeters. Therefore, it is not possible to create tension in the lining between individual elements, and it is necessary to observe a thermal gap of at least 3 millimeters.

In the northern regions, as well as in places with high humidity and close to the ground water surface, care should be taken to provide additional insulation and waterproofing of the cap before installation work. As a waterproofing material, a special polyethylene film can be used, or the foundation and base of the building can be treated with mastic, based on artificial or natural water repellent resins. As a heat insulator it is recommended to use polystyrene plates.

If the house is located in a marshy area, it is impossible to insulate the plinth with mineral or glass wool, because of the high hygroscopicity of these materials. If it is possible to purchase natural thermal insulators, it is necessary to give preference to those containing jute or flax.

Within the framework of this publication, we have tried to explain as much as possible the issue of installing decorative panels for the socle. The installation process should not cause any trouble for a person who, at least indirectly, encountered construction work.

For work, a standard set of simple tools is used, which is found in almost every household, so you do not have to buy anything especially.

In the video below, you can find more information on this topic.