Do you dream of creating a warm and cozy space in the house, apartment, and central heating batteries refuse to help in this? Then install your own hands a warm plinth - innovative development of modern heating systems.

Content

What are the advantages of a heating system

Before mankind there is a question on energy saving, it is necessary not only to save energy, but also to improve the system for minimizing heat losses. Modern homeowners are trying to acquire economical heating boilers, and from personal experience we can confirm that high-quality modern boilers are able to work in an economical mode. In this article we will tell you about an additional way to save heat in the house. Traditional types of heating in the form of radiators and heaters that produce the required amount of kilocalories of heat, begin to give way to innovative developments in heating systems. The use of a radiator version of heating has a number of drawbacks: the wall on which the radiator is located, heats and dries, and other walls remain cold. Therefore, the cold floor and walls create a feeling of cold and discomfort. Heating system "Warm plinth" can be confidently called the leader of heating systems, which can change the convection currents in the room and, of course, the microclimate.

Above and below the plinth

Made in the form of a conventional plinth, the heating system evenly distributes heat, forming a thermal curtain. Therefore, the heat shield, rising upwards, gradually cools down, without forming an excessive layer of heat under the ceiling. The heated wall and floor give heat to the room in the form of heat radiated by the heating system, creating a comfortable microclimate. In the rooms where the system is installed, there is no active dust lift, because the heated air is spreading slowly.

Types of heating Warm skirting and system design

There are the following types of plinth heating:

• water

• electrical

Therefore, the selection and configuration of equipment necessary for the stable functioning of the system must be made depending on the type.

Plinth warm water

In the version of water heating, the coolant circulates through the contours of the "Warm Skirting Water System" system with the specified parameters. This is water or antifreeze at the rate of 0.34 liters per 1 running meter of the heating system with a temperature of 40-85 degrees.

Warm plinth electric

For the option of a plinth, a warm electrical characteristic is that a tubular heating element with a power of 200 W is inserted in the lower tube of the heating module. for 1 running meter of the system. The heating elements are connected in parallel, the regulated operating modes are set and monitored using the built-in thermostats.

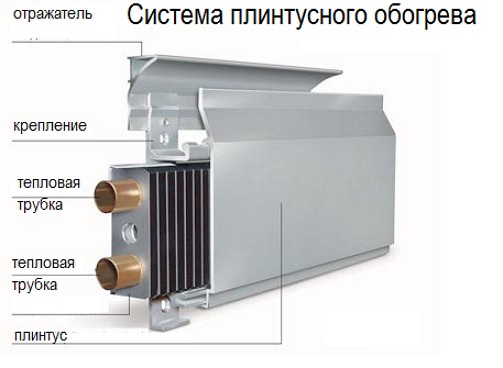

System design

Structurally, the warm skirting system is an aluminum box assembly. The skirting board consists of aluminum slats, 14 cm high and 3 cm wide, which is mounted around the perimeter of the room. Inside the protective box, a heating module of the heat exchange type is fixed on special holders.

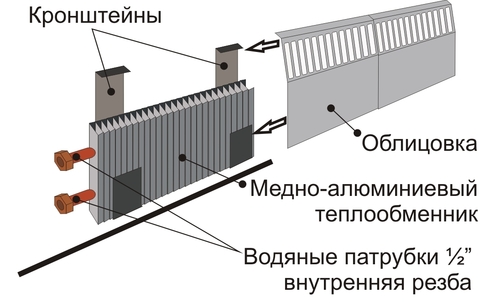

The heating module is a contour made of two copper pipes with brass lamellae at the ends. The diameter of the outer copper pipe is 13 mm, the inner diameter is 11 mm. Heating water heating modules are connected using a crimp nut or fitting. The coolant enters the plinth system along the supply pipes. For removing and supplying the coolant, use plastic pipelines with a diameter of 12-18 mm. of cross-linked polyethylene type PE-X, PE-RT.

For connection to the heating module, standard ½ "female adapters are used.

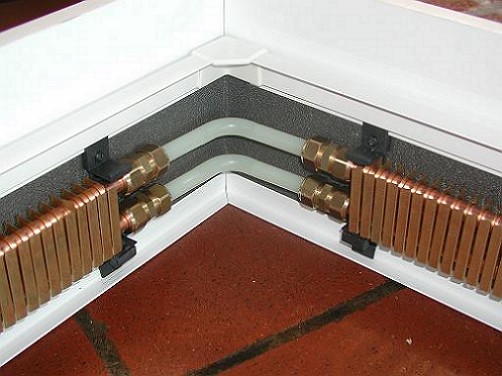

To connect the heat exchange modules in the corners use special rotary tubes. Rotary tubes are also made of cross-linked polyethylene PE-X. Polymer pipes are good in that due to the insignificant heat conductivity they do not allow to obtain a local overheating of the surface.

The joints of the aluminum profile are covered with plastic elements - plugs.

In addition to the basic working set of the construction of a warm plinth for the functioning of the system, it is necessary to use additional equipment:

• Distribution manifold

• Supply pipes

• connecting fittings

• Automatic control devices.

In the Warm Skirting System, the heating temperature is adjusted by means of a collector manifold, with which you can set the amount of heated water, its speed and temperature.

It is recommended that the distribution manifold be used in conjunction with drain and cut-off valves, as well as automatic air vent.

Installation and installation of plinth heating system

Installation of the heating system can be made independently. The basic measures for installation and installation of the baseboard heating system consist of the following stages:

• the preparatory

• installation of the main elements of the system

• Connect the system.

Water connection type

For the water connection, a plastic pipeline is first laid from the collector.

At the preparatory stage of installation and installation, the terminals to the connection points are prepared. The supply pipes PE-X or PE-RT (for the water version) are routed from the distributor to the installation sites. The engineering equipment is installed in accordance with the specification provided for the installation of the system.

At the stage of installation of the main elements of the system for the water version, the following elements are mounted:

• connection of heating modules with a coupling and rotary corner elements

• balancing of the heating circuits

• crimping

• adjustment and adjustment of the automation and control system.

Electrical connection type

For the automation system, a power cable is laid, the purpose of which is assumed at the design stage of the system. These are the points of connection of servo drives and thermostats.

Further installation of the system elements for the electric version is as follows:

• water heating element

• connection of heating modules.

After installation of structural elements and completion of finishing works

produce the final events:

• measurements of insulation resistance of the system

• Thermostats are set up

• Power supply.

The final stage after the installation of the main elements is the installation of upper decorative plastic panels, direct joint of panels and end caps.