The concrete foundation of the house is not comfortable to be constantly in a moist environment arising from the penetration of rain and meltwater into the ground, the seasonal rise of groundwater, and the reactive substances transported with these waters can have a negative impact on it. It is possible to get rid of the harmful effect of the environment on the waterproofing. Applying it during the construction of the foundation will avoid the need for its repair in the future, and, consequently, the expenditure of funds and time for the implementation of restoration work. There are several options for the implementation of a quality waterproofing system today, but practice shows that the most effective of them is liquid waterproofing.

Content

Types of waterproofing

On the importance of high-quality waterproofing disputes are inappropriate at all, but the developer raises the question of the correct choice of the type of insulation and material. When making it it is recommended to take into account:

- the depth at which groundwater flows,

- how real the threat of flooding the house with a case of high water or heavy showers,

- indicators of the soils,

- purpose of construction (residential building, bathhouse, barn, cellar).

When constructing the foundation, two types of waterproofing can be carried out:

vertical and horizontal. However, experts do not recommend underestimating the importance of the sand cushion under construction - it will help reduce concrete leaks during pouring the foundation, and in the process of operation - protect it from washing.

The following measures are applied to the horizontal waterproofing system:

- construction of a drainage system,

- backfilling of the foundation pit with a layer of clay,

- creating a sand cushion,

- execution of concrete screed, followed by its processing with bituminous mastic,

- laying layers of roofing material.

To vertical waterproofing works proceed after the construction of the foundation and the final hardening of the concrete. The process involves applying layers of insulating material to the vertical surfaces of the walls of the foundation.

Sometimes the option is applied with the use of roll materials - the main drawback of which is the impossibility of creating strong and reliable joints, usually their destruction occurs in a couple of years.

Bituminous waterproofing

The practical application of molten bitumen is not an ideal option:

- melted bitumen does not have a sufficiently high level of adhesion,

- its consistency does not allow filling small pores in the material,

- before the application of bitumen waterproofing, it will be necessary to perform surface treatment with a bitumen primer - a primer that is a resin dissolved in gasoline, the primer has a propensity for ignition, work should be carried out in compliance with fire safety rules.

The application of bituminous material is carried out in several layers - from 2 to 4. The heated bitumen should not be allowed to cool down - reheating will result in the loss of some of its qualities. To slow down the hardening process, a small amount of waste oil is added to the heated bitumen.

Difficulties arise with the preparation of melted resin:

- will require the use of a considerable amount of firewood,

- the very work with hot resin is dangerous in terms of getting burns,

- working people should be dressed in overalls and shoes,

- inconvenience is the propensity of bitumen to rapid cooling.

Positive aspects are the availability of bituminous material and its not high cost. Cons - the inability to provide a sufficient indicator of water resistance.

A more rational variant is the treatment of the foundation with finished mastic with higher insulation qualities. Apply it in two layers, it is not necessary to reheat before applying.

Waterproofing by plastering

One of the cheapest and simplest methods is to apply a cement based plaster mixture to the surface of the foundation walls with the addition of hydro-resistant components.

The mixture is applied very quickly and easily, with a spatula, serves simultaneously as a waterproofing and wall-leveling coating. To impart greater strength to the surface to be treated, a plaster grid is attached using dowels.

Positive moments:

- ease of application,

- low cost.

Negative - low level of waterproofing and fragility.

Liquid waterproofing for the foundation and its variety

Fortunately, all modern liquid waterproofing materials are practically devoid of the aforementioned drawbacks - their natural state during the application period is liquid, the polymerization process takes place in contact with the air, as a result of which the materials are converted into a solid or semi-soft consistency.

Since natural components are used in the process of manufacturing liquid waterproofing, it does not pose any threat to the health of people and belongs to the class of environmentally friendly products. The liquid formulations usually contain fire retardants or substances that suppress the burning process. The insulating mixtures are applied to the foundation, pre-treated with a deep penetration primer. Modern liquid waterproofing is a material characterized by high penetrating ability in relation to the concrete foundation foundation. It is applied liquid waterproofing for concrete very easily, special devices for performance of work are not required. The most common materials are:

- liquid rubber,

- liquid glass,

- two- or one-component sand-cement compositions.

liquid glass for waterproofing

As already mentioned, a person who does not have experience of performing construction works can perform liquid waterproofing with his own hands. Used liquid glass in construction for a long time, its name is due to the constituent components, which are also the raw material for the production of ordinary hard glass. As a matter of fact liquid glass is a solution of sodium and potassium salts, without color and smell, practice its addition in concrete with the purpose of increase of durability. The application of a layer of liquid glass to the surface also gives the water repellent properties.

You can apply liquid glass with brushes or a spray gun, preliminary application of the primer is not required - the liquid consistency allows the penetration of the waterproofing even into the smallest pores on the surface of the concrete. Treatment with liquid glass can be exposed to the external and internal surfaces of concrete walls or ceilings. The guaranteed term of this isolation is about five years.

Specialists do not recommend the use of liquid glass to impart waterproofing properties to the outer parts of the foundation.

liquid rubber for waterproofing the foundation

This variant of waterproofing makes it possible to create a membrane on the surface of concrete, which, thanks to the presence of latex in its composition, has good water-repellent characteristics. Acceleration of the polymerization process occurs due to the presence in the composition of the coagulant material - technical calcium chloride in a dissolved form. This type of waterproofing is very successfully used as a protection of swimming pools, roofs, artificial reservoirs.

Liquid rubber is applied with a sprayer, the material is able to penetrate into any size of the cracks and pores, create a waterproof membrane film.

To ensure a long service life of waterproofing from liquid rubber, one should adhere to such rules:

- apply the material to a low-fat surface,

- before applying liquid rubber it is recommended to apply a primer coat,

- do the work should be in dry warm weather,

- the polymerization process takes place for at least 24 hours,

- if the application is carried out with a sprayer, under high pressure, special construction equipment will be required.

If you are planning a waterproofing with liquid rubber, you can pay attention to such similar materials:

- Elastoplaz, which is characterized by a lower cost, but applied in two layers, it is possible to store the remainder of the material in a closed container;

- Elastomix, which has a higher price but is applied in one layer, the hardening process lasts about two hours, the remainder of the material can not be stored after opening the container.

If the device of the waterproofing system is self-made, then the application of these materials is possible with the help of brushes, but working with the sprayer will greatly simplify and speed up the surface treatment process. On average per sq.m. the foundation will need to spend about 3 kg of liquid rubber.

Positive moments:

- high quality of waterproofing,

- long service life,

- ease of application.

Negative:

- high material cost,

- not always have the opportunity to purchase it (lack of in stores and warehouses).

polymer liquid waterproofing for foundation on sand-cement basis

Liquid waterproofing of deep penetration is the most effective way to give waterproofness to concrete or any other porous material. In composition it can be one-component or two-component. To prepare the first one, it is sufficient to add the necessary amount of ordinary pure water to it, and secondly - it will require the addition of a special liquid that will start the polymerization process. Preparation of the mixture for work can take 10-15 minutes. The qualitative characteristics of both types of polymer waterproofing are practically the same. They can be applied with brushes or brushes, the application process is repeated 2 times.

Polymeric waterproofing of deep penetration, for example - Aquatro, Penetron, is ideal for the treatment of foundations:

- it is able to penetrate deep into the thickness of the concrete base by 10-15 cm and ensure reliable blockage of all cracks and pores present in the concrete,

- its quality does not decrease under the influence of high or low temperatures,

- the polymer base gives the treated material some elasticity and prevents the very possibility of its cracking,

- antifungal components that are part of the waterproofing mixture exclude the possibility of development on the surface of concrete and in its thickness of harmful microorganisms.

One of the main advantages of deep penetration impregnation is the possibility of its application on the inner surface of the walls of the foundation - this is very important in the event that repair work or foundation construction is carried out by one's own hands.

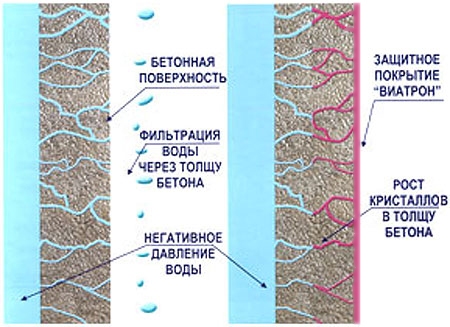

In addition to special additives, the waterproofing material includes high-quality cement and ground quartz sand. After the application of the waterproofing mixture on the wall surface, the penetration of the chemically active additives begins inward through the capillary courses; upon contact with water, insoluble crystals form which fill all the existing microcracks and voids. The concrete structure treated with mortar acquires water resistance, becomes stronger, dense, frost-resistant.

Another important advantage of a deep penetrating material is the ability to treat a wet surface, for example, a cellar that survived flooding does not have to be dried before commencing work. Moreover, the increased moisture content of the material promotes more active growth of crystals in the pores of concrete.

The fundamental difference between the deep penetrating impregnation is that it does not create a protective layer after polymerization - it enhances the qualitative characteristics of the impregnated material. Guaranteed service life of the treated wall is about 15 years.

From the shortcomings of deep waterproofing, one can call the low prevalence of the material and its relatively high cost.

How to choose a suitable type of waterproofing material

First, the foundation can be considered protected from moisture in the event that the procedures for its horizontal and vertical waterproofing are carried out. If the stage of horizontal insulation has been performed poorly, then it is better to apply roll-bitumen protection or liquid rubber - it will help to cover all the cracks between the slabs, which can become ways of penetration of moisture.

For the waterproofing of the tape foundation, plaster, bitumen or deep penetrating protection can be used.

In the construction of pile-screw foundations, additional processing of metal parts with a solution with anticorrosive properties is required.

Tips from specialists:

- Builders consider the most effective option a combination of different methods. At the same time, they do not recommend saving on materials - in case of need for repair, it will require substantial financial expenses and a great deal of time.

- If there is no confidence in the correct choice of material - it is best to consult a specialist.

- The method of waterproofing should be selected before the foundation is poured.

- To increase the effectiveness of the roll method of waterproofing, it is recommended to superimpose the roofing material in several layers, creating a layer of bitumen between them.