With the easy supply of the American industry of roofing materials in the 1880s, mankind acquired roll bitumen material, which was a prototype of roofing felt and modern bitumen shingles. The design and impregnation of smooth shingles (shinglas) of tile perfectly suited to the light and was used for the construction of roofs and roofs.

Content

Modern roof tile shingles with bitumen-impregnated cardboard sheets have nothing in common. On the contrary, it is a material convenient for installation with patented know-how solutions in the form of transport protective film of the lower layer. It is now a pleasure to install. Of course, if you own the technological subtleties of the installation of hand-made performance.

Bitumen shingles - features and properties

Innovative technologies for creating roofing roofing materials today are gaining increased interest and demand.

Features and benefits of bituminous shingles, the types of which are supplemented each year with new texture and shades, provide distinctive characteristics and properties:

• high level of waterproofing and excellent noise absorption

• possibility to create a coating on curved surfaces

• Insignificant weight of the roof assembly

• affordable and inexpensive installation.

The conclusion is that roofing from bitumen shingles is a practical and profitable option for roofing. For comparison with competitive cover materials, bitumen shingles, whose price is much higher, can provide a high consumer level.

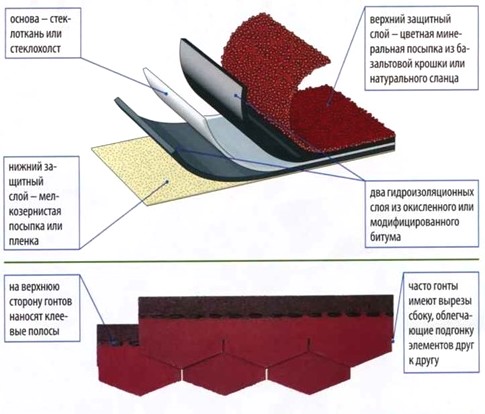

How is tile made of bitumen

The secret of the success of the material is laid in the technologically thought-out device of bituminous shingles. According to the experts who produce the installation of shingles, superiority and convenience provide:

• the tie shingles, which imparts strength to the material - fiber glass shinglas

• Bituminous composition, which gives the ability to retain the form of the roof

• transport film, which protects the adhesive layer prior to the start of the assembly activities

• Mineral crumb (granulate) of the decorative layer in the form of powder.

We will show that the consumer qualities achieved are laid down in the properties of the bituminous compound, which ensures an unchanged consistency and chemical stability of the covering material. Naturally, to preserve the superiority of the roof allows the installation of bituminous shingles and specific ways of fastening the main elements of shingles.

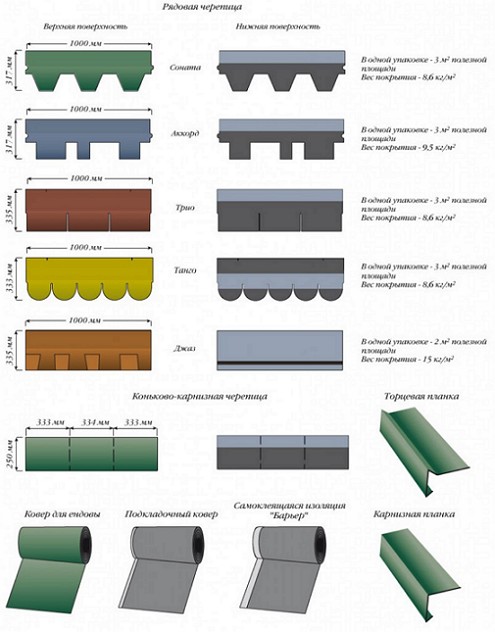

Dimensions and shape of tile cuts

The basic unit of the roofing tile material is shingles in the form of separate plates according to the configuration and symmetry. We will not hide, the shape of the shingle and the size of the shingles do not affect the quality characteristics of the material and represent the assortment range.

There are several forms of cutting ordinary and skate-cornice tiles. The most popular forms of slicing shingles for a roof of bituminous shingles are: rhomboid, rectangular, hexagonal and brick.

Analyzing the experts' feedback on bitumen shingles, the methods of mounting shingles of any configuration are identical.

Correct installation of shingles

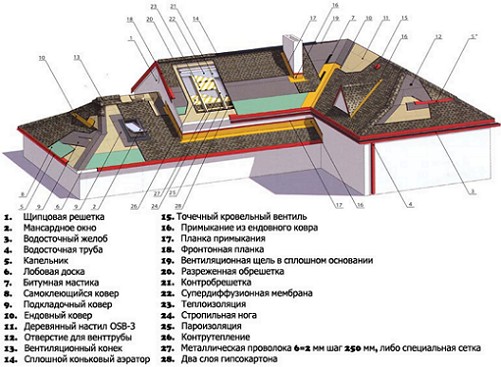

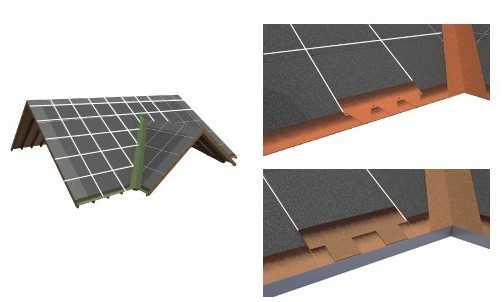

Enlarged installation technology involves the following activities:

• Creation of roof ventilation

• installation of roofing base

• Layout of the backing layer

• installation of end and cork strips, rails

• orderly installation of shingles from below

• the device of junctions

• installation of the ridge part of the roof.

Each stage of installation has features and nuances of laying or fastening, which are kindly shared by specialists.

Advice of specialists

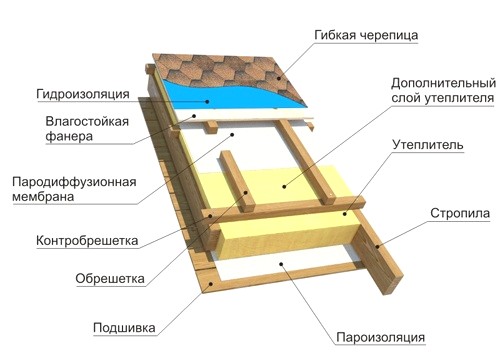

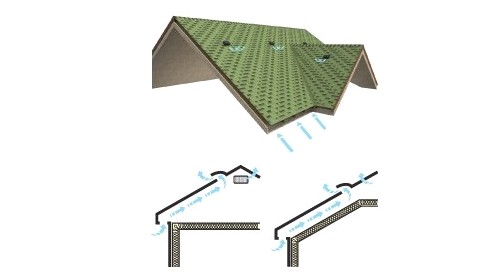

need for roof ventilation

To fully ventilate the bitumen roof, you need 3 ventilation channels:

• Supply duct, located in the lower roof part

• air circulation channel above the thermal insulation layer

• the exhaust duct at the top.

The exclusion of one of the recommended ventilation channels violates the ventilation of the roof.

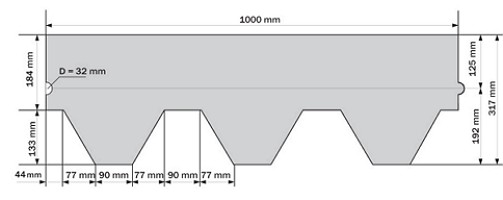

type of roofing base

The base of the roofing for the tile should be smooth and strong, therefore OSB-3 boards, waterproof and plywood boards are chosen for the roofing site. The thickness of the base layer is chosen relative to the rafter spacing.

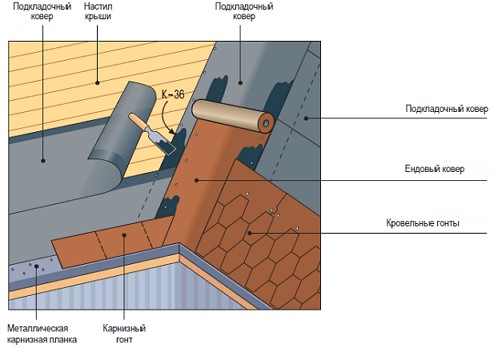

what material is used as a backing layer and its layout

A continuous underlay carpet with an angle of inclination of the roof to 3-5 ° is arranged from a roll polymer material OC-1.5 or PE-1.5 with a top-down layout. Orientation of the material: film down, granulate upward with an overlap of up to 10 cm and fixing the edge with roofing nails (20 cm pitch). Necessarily cover the end parts, valley and horse, seams and joints are sealed with mastic.

installation of the cornice and end strips

On top of the created backing layer, the overhangs of the cornices are placed with overlaps of 5 cm. The strips are nailed in a zigzag manner in 10 cm steps.

At the end of the installation, the slats make a marking of the slope on square cells of 1x1 m, which allow orienting the layout of the shingles.

orderly installation of shingles

The first row is recommended to be laid out from the center of the ramp. The gonts are arranged alternately from 4 packs. The gon is placed on the plane of the roof and the transport protective film is removed from the lower layer. Orderly installation of shingles starting from the starting strip is recommended to be done in a diagonal way with a shift of ½ of the shingle.

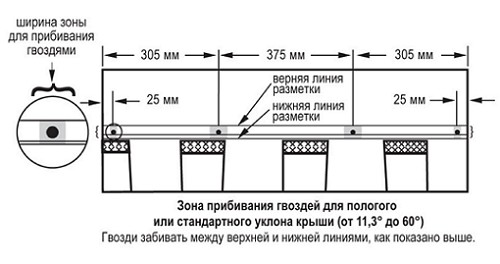

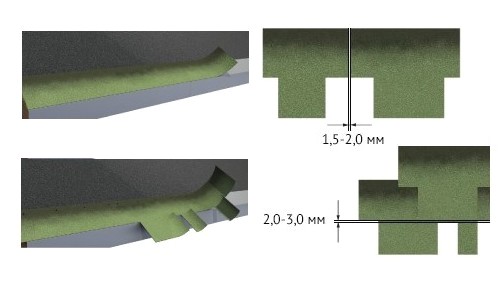

Each shingle is placed on the roof and fixed with 4 roofing nails: 2 at the top, 2 at the bottom. Between adjacent shingles, it is necessary to leave a gap of 1.5-2.0 mm and leave the allowance on the lower laid shingle 2.0 mm.

contiguity assembly

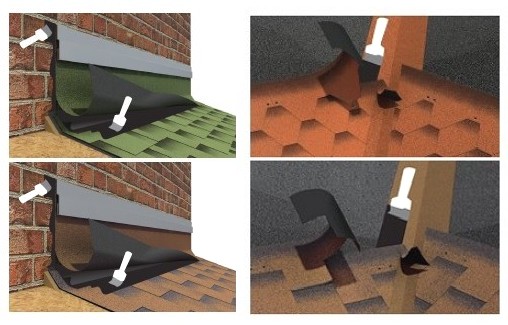

abutment

To create an abutment with a vertical surface, nail the rod with a right angle, which leads to the edge of the shingles. Then put mastic on the carpet of the valley, and the strip is turned on the shingles. The upper part of the insulated junction is covered with an apron.

endowment

For installation, the valley shingles are cut to a width of 15 cm and laid in a dock. The edges of the shingles in the valley are cut with a roofing knife on the board. The edges along the cut line are glued with mastic along the width of 10 cm.

how to install a ridge part

On the ridge part and roofing ribs mount separate fragments of shingles, which begin from the side opposite to the wind load. Laying the ribs of the roof with fragments of shingles is made from the bottom with an overlap of up to 5 cm and subsequent fixation of the ridge tiles by 4 roofing nails.

More detailed information on the installation is shown in the video.