The central sewer system is not always available to residents of small towns and the private sector. Very often the only available option for diversion and collection of domestic waste is a septic tank or a cesspool. It is very important, when planning the arrangement of a cesspool on its site, it is necessary to correctly calculate the volume of wastewater and the way to pump and dispose of it, and, based on this, choose the type of cesspool. Below we will look at the types of cesspools that can be made on your own backyard or cottage area, as well as equipment and methods for pumping domestic sewage.

Content

Types of cesspools

All cesspools can be divided into three main types:

- Absorbing cesspools (pits without a sealed bottom).

- Hermetic cesspools.

- Septics

The simplest and most budgetary option for equipping a cesspool is a conventional storage tank that does not have a sealed bottom. What are the advantages of such a cesspool? First, such a cesspool without pumping can last a long time, depending on how dense the ground is on the site. Secondly, such a cesspool of the house can be of relatively small size, and the device of the cesspool does not need to spend a lot of money.

However, such a reservoir has a number of significant drawbacks. One of the main - household waste from the pit fall immediately into the ground, which can harm the environment and health. In addition, a pit without a sealed bottom can not cope with a large volume of sewage. Another drawback - the pit eventually sinks. Even if there is sandy soil on the site, and water initially leaves very quickly, in time, the runoff will be absorbed all the worse because of accumulation at the bottom of the silt. The pit gradually becomes shallow, and it falls asleep, and it is necessary to dig a new one. This is another disadvantage of a cesspool without a bottom - the useful area of the plot decreases.

Hermetic cesspit is not dangerous for the environment, it is much more convenient to operate. The sealed pit is a closed tank that does not allow water to pass through. The building material for such a pit can be concrete, brick, plastic, gas silicate block, etc. Such a pit requires frequent pumping, for which it will be necessary to call a sewer machine, and with increasing service life it will have to be done more often. And if a large volume of drains constantly flows into the sealed cesspool, then the car-scavenger will have to be called about once a week, since sludge will accumulate at the bottom of the pit, and the visit of the sewers will not be so cheap.

Important point: by arranging a private sewage system, try to calculate its volume - it should roughly coincide with the capacity of the sewage machine. Thus, until her next visit, the cesspool will not have time to overflow.

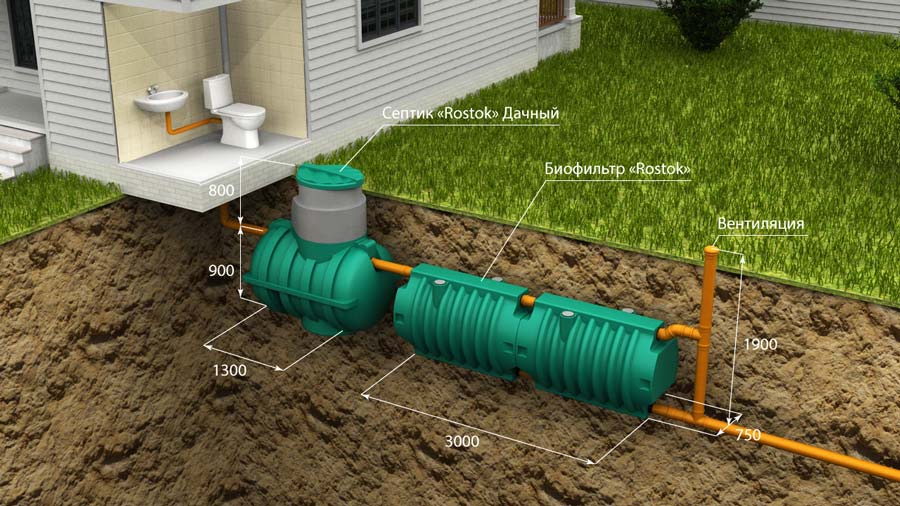

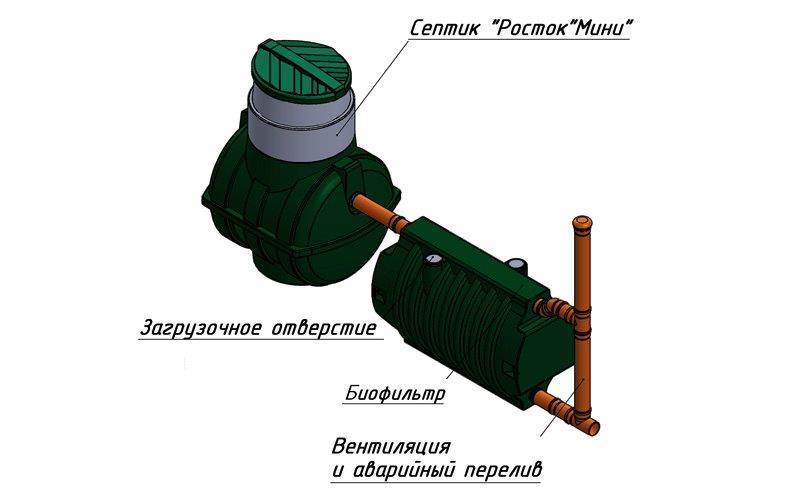

The most reliable type of cesspool, which can be arranged on its site, is a septic tank. This construction is a well, the bottom of which is lined with a thick layer of crushed stone, gravel, or broken bricks, which serves as a filter for drains. The bottom filter produces an initial, rough cleaning of the drain, then the water enters the ground, where it gradually clears. Thus, the septic tank is filled rather slowly, and the minimum amount of contaminated water gets into the soil.

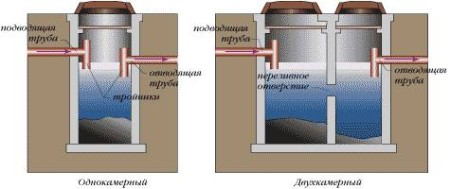

A septic tank can be single- and multi-chamber. The multicameral septic tank is distinguished by its good environmental friendliness, because it involves deep water purification, which can even be used for irrigation. However, the device of the multi-chamber septic tank is labor-intensive and expensive.

If there is a desire to work independently on the device of a cesspool, and there are no extra means, you can use worn-out automotive rubber.

Tires can be completely "bald", but without holes. This option allows you to save not only due to, more simply, garbage, which you can get for a penny at the nearest tire fitting, but also on the device of the concrete base, which can be successfully replaced with a pillow made of rubble and sand. Its thickness should be about 40 centimeters. On top, you can make a 10-15 centimeter cement screed.

To increase the volume of the rubber tank, the side parts of the tires are cut.

It is desirable to connect the tires with each other using bolts. Inside the rubber well a sewage pipe is being built - and the cesspool is ready.

Absorbing pit by one's own hands

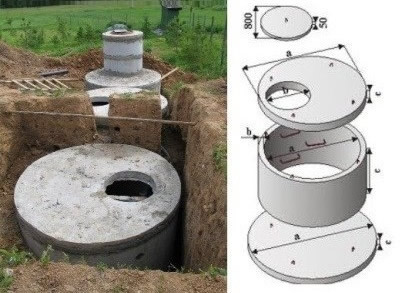

This design attracts the owners of their own countryside by its simplicity and the possibility of not often resorting to the services of sewers. The walls of the cesspool can be laid out of a brick or a gas silicate block. It's even easier and faster to install concrete rings in the well, but in this case you can not do without a crane manipulator. Consider a variant of a cesspool using concrete rings in more detail.

So, the concrete rings with a diameter of one meter will need three pieces. First, you need to excavate the pit, the shaft, whose diameter should exceed the diameter of the ring by about 80 centimeters.

At the bottom of the shaft, along the perimeter, make a concrete screed, leaving the central part empty. Screed will serve as the basis for the lower ring. In the lowest ring, a number of holes are drilled in order that the water can freely move out of the hole. You can buy a concrete ring with the holes ready.

The diameter of the holes should be about 5 centimeters.

Important point: do not make a well depth of more than three meters, as the hose of the sewage machine may not reach the bottom and extract a muddy residue.

The lower part of the well is covered with a simple filtering composition: broken brick, gravel and sand. Its thickness should be about a meter.

The same composition falls asleep and the outer space between the rings and the ground. Directly before filling, the outer and inner parts of the rings must be treated with bitumen mastic for waterproofing. You can save a little bit of bitumen mastic and coat the rings with a layer of greasy clay on the outside. At the end of the work, the shaft of the well is closed with a lid with two openings - one for pumping out the drain, the second for venting the cesspool.

The walls of the absorbing well can also be laid out of bricks. For this purpose, and a brick "used" - the main thing is that it does not crumble and crack. Brick masonry takes much more time and effort than installing rings. But for laying the brick in the sewer shaft, the mason's skills will not be needed - nobody will see the clutch anyway. The main thing is to properly tie the corners. The bricks are put in staggered order, leaving holes for drainage of water.

Before the beginning of the laying on the bottom of the pit, a cement screed is arranged around the perimeter - just like in the case of concrete rings. The screed should last for 7-8 days. In the process of laying bricks, it is necessary to leave holes under the sewer pipe. It should be below the freezing point of the ground so that in winter there are no problems with drainage. Sewage pipe should have a smooth, not too steep slope from the house towards the cesspool.

Ready-made cesspool kit

The most convenient and fastest option is to make a cesspool in accordance with the accurately sized dimensions of the finished components. The only insignificant drawback is that the manufacturer himself sets the parameters of the volume of the structure. But since the product is released with the expectation of an average consumer, it will not be difficult to find a suitable kit.

First of all, they dig a pit, taking into account the dimensions of concrete components. At the bottom of the sewerage well, a concrete cushion is arranged and left for a week until the concrete gets stronger. During this time, the concrete is dampened with water from time to time.

After that, you can order delivery kit. Typically, the implementers provide the installation of concrete sewerage parts using a manipulator mounted on the car. When installing between rings, it is recommended to make a jumper for separating dirt and treated water.

As is clear from the foregoing, there are quite a lot of methods for arranging a cesspool on its site. It remains only from the variety of options to choose the most suitable, which meets individual needs.

Pumping out cesspools

Cleaning the cesspool can be done by contacting the suction trucks for help, but you can do it yourself.

In a specialized company engaged in pumping and recycling of domestic sewage, it is guaranteed to provide the appropriate services, completely clearing the cesspool or septic tank from the waste. For this you will have to pay a certain amount.

In addition, it is necessary to ensure the free entrance of a bulky car to the cesspool. It must also be ensured that the machine picks up all waste to the bottom, only then the cesspool or septic tank will function normally.

Self-cleaning of the cesspool can be done manually or by means of a fecal or faecal-drainage pump. Manual cleaning is carried out only if the pit is of small volume. It will take a rope or pole, to which a bucket is attached.

It is also necessary to protect all exposed skin areas from contact with contaminated drains. Will not interfere with the cotton-gauze dressing or a respirator. It is clear that the pleasure of such work is very doubtful, and a pungent smell throughout the site is guaranteed. For a regular pumping out of the cesspool, it is better to purchase a fecal pump and a capacity of a suitable volume for temporary storage of pumped out drains.

Household fecal pumps for cesspools

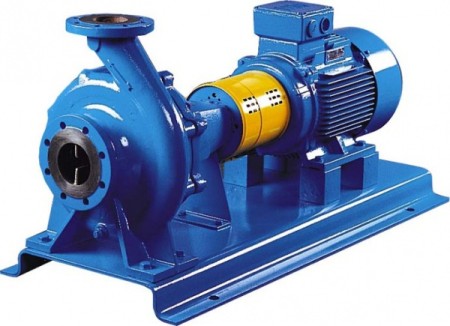

The main difference between faecal pumps and other models is that they can be used to pump out a liquid containing solid deposits without problems.

Such equipment is very useful for the owners of sites that are subject to regular flooding with groundwater, since with the help of fecal pumps it is possible to pump not only sewage from cesspools and septic tanks, but also water from the basement and the house.

All fecal pumps for the design and installation method are divided into several types:

- Surface pumps.

- Submersible pumps.

- Semi-submersible pumps.

It should immediately be noted that surface and semi-submersible pumps are not suitable for pumping out cesspools. There are several reasons for this, but the main thing is the absence of a grinder for solid particles. Since pumping septic tanks and cesspools should be made to the very bottom, the pump will inevitably have to pump solid fractions, and it is desirable that the pump is at the bottom of the tank. And although surface pumps are easier to install and dismantle, only a submersible pump can handle one hundred percent with pumping out the cesspit. Before starting the work, you should carefully read the instructions, as the parameters and operating conditions of different models can vary significantly.

Submersible faecal pump is installed on the bottom of the cesspool or septic tank. In this case, special guides are placed on the wall of the tank, and a branch pipe is lowered to the bottom. The pump is lowered on a chain or a cable. The pump is mounted on the nipple under the weight of its own weight. Such equipment is popular due to its convenience and ease of use.

The pump's capacity must correspond to the volume of liquid that must be pumped out and the height at which it needs to be lifted. The maximum power of the submersible pump can be 40 kW. A pump of this power can pump about 400 cubic meters of liquid per hour, lifting it from a depth of 20 meters. But there is no point in buying such a pump for your own site. Calculate the power of the pump for each particular case is very simple with the help of the formula: pit depth + hose length / 10. For example, the depth of the septic tank is 8 meters, the hose is needed for 40 meters of length: 8 + 40/10 = 12 meters. That is, when buying a pump, you should give preference to a pump capable of raising sewage to a height of 12 meters or more. A small margin of power will allow the pump to run without unnecessary load.

As we have already mentioned, such a useful thing as a chopper is mainly equipped with submersible pumps.

As for surface and semi-submersible models, they have only a hose inside the drain, and the pump itself is near the pit. Thus, all the solid particles must first fly along the entire length of the hose, and crush already at the top. For this reason, surface hoses often hose hoses. In addition, in these models, the chopper is installed only at the customer's request, it is not standard.

Submersible pumps have no competitors in terms of protection and resistance to aggressive environments. Virtually all models are designed for 10 years or more. So, you can buy such a pump for a cesspool, install it, and that's it. Automation will react as soon as the level of sewage rises to a certain level, and the pump itself pumps out everything. But there is one necessary condition: a system of settling tanks must be installed on the site or a suitable capacity for the subsequent removal of wastewater is adapted. Of course, it is possible, by the simplicity of the soul, to take the hose to the nearest gutter, or simply to some wasteland outside the site, but in this case be prepared for the neighbors to promptly inform about your self-activity "where you should go."

And finally: try not to be tempted by the small price of Chinese handicrafts, and choose the pumps of proven manufacturers: SFA, Sprut, Grundfos, etc.