Technologies of energy saving and thermal insulation of residential and industrial buildings are developing rapidly, new materials are constantly appearing, which differ greatly in the mechanism of their action from heat insulators that were used before.

One of such materials is liquid heat insulation armor, or, as it is also called, heat paint. In this article we will consider the most popular brands of liquid thermal insulation: "Armor", "Isollat", "AstraTech", their characteristics and scope.

Content

- 1 Liquid insulation - what is it?

- 2 How does the liquid insulation work?

- 3 Liquid insulation for facades

- 4 Liquid body insulation for work in winter

- 5 Application of liquid heat-insulating materials to hot pipes

- 6 Liquid heat insulation "Armor" - scope and technical characteristics

- 7 What heat paint to choose?

Liquid insulation - what is it?

Teplokraska is the newest material with the help of which a very thin heat-insulating layer is created on the insulated surface. Liquid heat insulation has truly unique qualities, due to which it is possible to achieve a tangible effect in saving heat with an insulator layer 1 mm thick. Like many of the latest developments, heat paint is a product of the space industry. Excellent proven in this industry, liquid insulation began to be actively used in construction.

The application of liquid thermal insulation is carried out with the help of a brush, a roller, or by airless spraying. After the material is completely polymerized, a thermal insulation layer is formed on the insulated surface, which has excellent energy-saving characteristics. The coating acts as a "thermal mirror", thus ensuring the preservation of heat inside the room.

Heat paint consists of the following components:

• Filler. It is a mixture of ceramic, glass and polymer balls, invisible to the naked eye. Inside the balls are filled with air.

• Binder. It is made of latex or acrylic.

• Additives. The composition of the additives depends on where it is intended to use the heat paint.

The composition of the heat paint directly depends on its properties, as well as the requirements for the insulated surface and, accordingly, the method of applying the material. Therefore, in order to get the desired result, before buying the heat-color it is necessary to pay attention to its composition and scope.

How does the liquid insulation work?

Heat, as everyone knows from the school course of physics, is transmitted in three ways:

- Thermal conductivity. Thermal energy is transferred from a warm object to a cold one. The thermal paint contains only 20 percent of the components that can conduct heat.

- Convection. Heat is transferred by the substance itself. Due to the fact that most of the mass of liquid heat insulation is made up of balls, the convective losses are negligible.

- Radiation. Heat is transferred by the internal energy of the heated substance. Thanks to all the same hollow balls, the heat paint reflects and dissipates heat. Virtually 90% of the heat energy is reflected and remains in the room. The principle is somewhat similar to how a thermos works.

Liquid insulation for facades

Facade heat paint can be used for warming both domestic and industrial facilities. The most popular brands of facade liquid insulation: "AstraTech", "Isollat", "Armor Classic", "Armor Facade", - is also used for insulation of wooden buildings.

In the insulation of the brand "Izollat" contains special substances that provide a self-cleaning surface - rain washes off the surface of all dirt and dust.

Appointments of facade insulation:

Reducing heat losses through the facade to a minimum, saving on air conditioning in the warm period.

• Warming of internal walls.

• Warming of balconies, loggias.

• Warming of floors and basements.

The application of heat paint to the internal and external walls of the building helps not only to save heat and save on heating, but also prevents the appearance of fungus, mold, condensation and icing of the walls.

For buildings that need additional protection from a fire, there are special modifications of the heat paint that have the combustibility class "NG": Fire Resistance Armor, Akterm Fireproof, Corund Vulcan, Akterm NG.

Before applying liquid thermal insulation, the surface must be properly prepared, otherwise the consumption of liquid thermal insulation will increase, and adhesion problems may occur. The surface treatment instruction is attached to the material, but in most cases an acrylate primer of deep penetration is used.

If you believe the numerous reviews of customers, then cover the whole of the facade with heat-painting is impractical. But the heat-insulating treatment of certain areas - for example, slopes and other hard-to-reach places gives an excellent result.

Liquid body insulation for work in winter

It differs from other analogues in that it can be applied to the surface at negative temperatures. This includes such brands as "Akterm Nord", "Corund Winter", "Armor Winter".

The thermal paint "Akterm Nord" retains its properties at a temperature of -300C. As a solvent, a mixture consisting of white spirit and solvent is used for this heat-insulating material. Before applying the paint "Acterm Nord" you must thoroughly clean and dry the surface. When working with this material there are restrictions on the humidity of surfaces: for plaster and brick, no more than 5%, for concrete 4%. The humidity of the environment should not exceed 75-80%.

This heat paint is a water-based system. It contains a mass of microgranules with closed pores. Microgranules are in a solution of silicone-modified resin. As additional components, various plasticizers, fungicides and biocides are used.

Application of liquid heat-insulating materials to hot pipes

For the insulation of various kinds of pipelines, chimneys, ventilation and air ducts, the following heat-treating grades are used: "Corund Classic", "Acterm Standard", "Keramoizol".

In order to achieve the maximum result, a so-called "sandwich-technology" is used in pipe insulation, according to which layers of liquid insulation alternate with layers of glass fiber having a thickness of 0.5 mm. A total of 4-5 layers are applied. To make the surface smooth, a special varnish is applied to the last layer.

If it is necessary to isolate the polymer pipe, a bond test is first performed. If the surface of the pipe is dry and clean, then no problems should arise.

Liquid heat insulation "Armor" - scope and technical characteristics

The very name of this thermal insulation material indicates that it represents a reliable protection. The material was developed at the Volgograd Innovation Resource Center. The basis was taken by American developments, on the basis of which it was possible to obtain improved thermal insulation material at an affordable price for the average consumer.

Why is so popular liquid thermal insulation armor reviews about which among buyers, at this time only positive?

The manufacturer presents a wide range of products: Armor Classic, Armor Anticor, Armor Winter, Armor Facade, Armor Light. Each type of paint has clearly defined and tested specifications. Therefore, there will be no problems with the choice of the insulator and the way it is applied.

All products of "Armor" brand are ecologically clean and safe for health. Thermal insulation armor does not burn, it is easy to apply to all types of surfaces, the service life of thermal insulation is several tens of years.

And if you decide to stop your choice on this brand, then the thermal insulation of armor can be bought much cheaper than analogues, since this insulation is made in the territory of Russia.

heat color "AstraTech" - the main characteristics

"AstraTech" is the newest heat-insulating material on a water basis, having in its composition microscopic spheres of ceramics. Acrylic polymers are used as a binder.

This heat paint is used in the energy field, in construction for the insulation of walls, facades, floors, roofs, slopes, water pipes with hot and cold water, ventilation and air conditioning systems. "AstraTech" creates on the surface an ultrathin heat-insulating layer, which prevents the formation of condensate, protects the surface from corrosion, mold and fungi. The paint can be applied to concrete, polymer, brick and metal surfaces. "AstraTech" can withstand temperature changes from -600С to + 2500С.

The paint is not toxic, environmentally friendly, absolutely does not support burning. At temperatures above 8000C, the insulator begins to decompose into carbon monoxide and nitrogen, which significantly slows down the combustion.

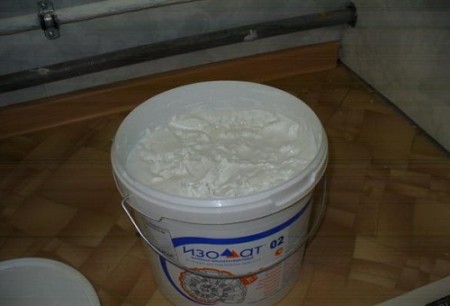

liquid heat insulation "Izollat". Warming with liquid thermal insulation of metal structures

This grade is recommended for applying to the surface quickly erected metal structures: garages, hangars, warehouses, etc. The maximum effect is achieved with two-sided surface treatment - outside and inside. In this way, the paint protects the room from inside from heat loss, and from outside from excessive heating in the warm season.

If it is necessary to apply Izollat to galvanized metal, the surface must be degreased first, since adhesion problems may occur. For full confidence on the galvanized surface, you can apply an inexpensive primer, for example, GF-1.

"Isollat" badly sticks to stainless steel and aluminum because of the oxide film formed on the surface of these metals. Therefore, before applying the heat paint to these materials, it is necessary to pre-treat them with a primer.

What heat paint to choose?

We hope that the above material will, to some extent, help determine the choice of a liquid heat insulator. And in order to simplify the issue of choice of paint as much as possible, below we will give approximate prices for heaters, designed for walls and other elements of the construction of a residential house.

"Korund classic" cost 10 liters - 3700-4960 rubles.

Astartek Universal "cost 1 liter - 415-450 rubles.

"Armor Classic" cost 1 liter - 380-415 rubles.