Any owner of a country plot, especially a city resident, spoiled with comfort, understands the need for a water main in the house. Without your own water supply, you can not provide a full-fledged care to your site, it is impossible to wash things normally, to bathe in a bath or take a shower, and to wash the dishes. Russian bath with their own hands built - this is the place where a person rests with his soul and body. And what a rest if in the head of thought, if there is enough water, how much more to bring, etc. Therefore, the owners of their own suburban areas sooner or later think about settling in their own possessions of a water pipe.

Conduct water on the site and in the house with their own hands - significant savings and invaluable experience, which, undoubtedly, will be useful for further maintenance and repair of the water pipe.

Content

Autonomous water supply, device

When settling out the suburban area the issue with the water pipe is solved even at the stage of designing the future house: a plan is drawn up, the layout of the water pipes, costs are calculated, materials are purchased. For installation of the boiler-water-measuring unit, a small room with an area of approximately 2-3 sq. m.

If the water input and the necessary equipment is installed in the same room, it is convenient to monitor the water supply and regulate it, as well as to eliminate possible malfunctions.

The autonomous system of water supply for a country house consists of: a metal, metal-plastic or polypropylene pipeline, with the necessary number of cranes and fittings, a submersible or surface pump, automatic systems for regulating the system pressure, an expansion tank (accumulators), filters, a boiler for heating water.

Quite often in the network there is such a thing as "winter water supply". "Winter" does not mean that this water pipe can only be used in winter - it is a capital system that works all year round, well insulated on the entire length - from the source of water to the house.

As a source of water on a suburban or suburban site, a central water supply (if any) is used, a prefabricated well, a well or a spring chamber. Each option has its own advantages and disadvantages. If we talk about the well, then the water from it, of course, is much cleaner than from the well, but the development of the well at the site is associated with high costs. It is much cheaper to dig a well, install a submersible (with enough water) or a surface pump and filters for cleaning.

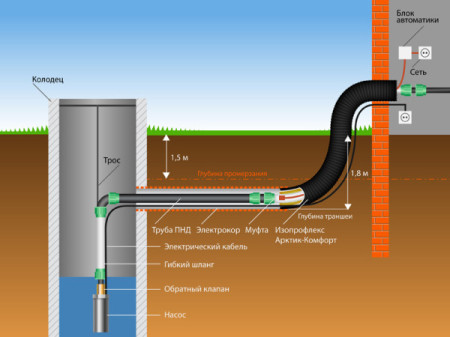

submersible pump

It is most often used in wells. Sufficiently powerful equipment - in the free sale there are "underlings", without problems, supplying water to a height of 20 to 60, and more meters. Such a pump is worth buying if in the well a powerful inflow of water and its level is high enough, and also if the well is far from the house. The submersible pump must be equipped with a check valve, so that the rubber "pear" inside the accumulator does not squeeze water back into the well. Quite often the accumulator, together with the automatic system that regulates the water supply, is installed in a specially equipped pit right near the well or well. As practice shows, all this equipment is better to install in the house - it is almost noiseless (only small clicks of automation are audible), it will last much longer in a warm room than in a wet pit, and it is much easier to solve all kinds of problems in the room. Do not just install the accumulator on the second floor of the building, best of all - in the basement, in order to minimize the damage in case of water leakage.

surface pump

Establish if the well has a small water level - less than 5-6 meters. Typically, surface pumps are installed indoors, connecting a source of water to the pipeline.

pumping station

This is quite noisy equipment, therefore it is installed mainly in a specially equipped insulated pit near the water source. It consists of a hydraulic accumulator, an electric pump - an "impeller" and an automatic control unit regulating the supply of water.

Installation of an autonomous water supply system

How reliable and durable the water supply will be, depends to a large extent on the quality of the pipes. The water supply system is not created for one year, and only high-quality and reliable materials are worth buying. Pretty well proven polyethylene pipes with a diameter of 25 mm

as well as polypropylene welded pipes of the same diameter, retaining tightness even at a negative temperature.

To connect polypropylene pipes a special soldering iron is used. It is worth this tool within 2-3 thousand rubles, you can buy it in almost any specialized store.

You can also take a soldering iron for rent, which will cost about 300-400 rubles a day. When calculating the length of the PP pipeline, it is necessary to take into account that each welding "steals" approximately 8 cm of the pipe. Pipes are laid, focusing on the arrangement of rooms in the house. If you plan to lay pipes in a suspended state, they can be hidden under a suspended ceiling - this option will be optimal for a kitchen or bathroom.

In addition, the "top" location of the water pipe has its advantages: the water warms up quickly and can be drained promptly. To maintain the pressure in the pipes, an expansion tank is necessary. The accumulator with capacity of 100 liters freely provides a two-storey house with water. It should, however be taken into account that the expansion tank does not gain all capacity - 100 liters. Water collects a rubber "pear" inside the tank, and this is about a third of the volume - for example, if the automation is adjusted to a pressure of three atmospheres, then in the tank will be about 35 liters of water.

In the boiler unit, it is better to start the installation of a water pipe with the installation of a water heating tank and an expansion tank. Expansion tanks for heating manufacturers paint in red, for water pipes - in blue.

installation of water purification filters

To purify water from suspended solids, a multi-stage water purification system is required. Today, stores offer a very large range of filters, there is something to choose from. Filters must be purchased, focusing on the composition of water in the well or well. For example, if the water in the well has an excess of iron, then the domestic water supply must be equipped with two filters that effectively remove excess iron from the water. The first filter is ion exchange, removing excess iron from the water.

The cost of a high-quality ion-exchange filter is approximately 5000-6000 rubles.

The second filter - coal, is used for mechanical and chemical water treatment.

Before selecting filters, a sample of water from the source must be submitted to the laboratory for analysis. If the test results are unsatisfactory, put additional filters, and water must be boiled before consumption.

Temporary or "summer water supply"

This option is suitable for summer residents who come to the city only in the warm season.

The main purpose of the "summer" water supply system - watering the garden and beds, and satisfaction of household needs. Before the onset of cold weather, this water pipe is completely dismantled, washed and canned. Such a water pipe can be made without special problems on its own, and it will be inexpensive. For installation, flexible pipes with adapters can be used. The main load is necessary for connecting elements, which are made of galvanized steel or plastic. Metal products are more reliable, and are somewhat more expensive, however, for the arrangement of a temporary water pipe, plastic is also quite suitable.

The temporary water supply system can be arranged in several ways:

Lay the pipes directly on the surface of the ground.

Advantages: simple and quick installation and dismantling. Disadvantages: lying on the surface of the pipe is very easy to damage.

Bury the pipes in the ground for 15-20 centimeters.

Advantages: the system is protected from possible damage and does not create inconvenience in the process of operation. Disadvantages: the need for excavation, for the winter pipes will have to be dug and dismantled.

To the end of the season it was easy to drain all the water from the pipes, arrange a slight slope with a valve at the end. When installing both summer and winter water pipes, you must carefully monitor the protection of the electrical network. To do this, only sealed connectors and sockets are used.

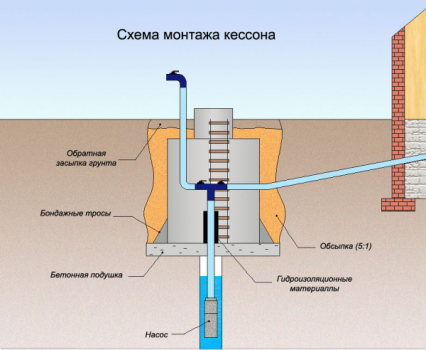

Warming of the well

For most country and suburban areas, the source of water is a well. In the summer, there are no problems with its operation. But in winter there is a real risk of freezing of the feeding and casing pipes. To prevent this, you need to think in advance how and how to insulate the well. You can go in a simple way and use for the warming up materials: leaves, sawdust, hay, straw, peat. More effective is the use of foam and mineral wool. A radical solution is the arrangement of a caisson, a metal or plastic well around the well, which is closed for the winter with a heated lid.

In any case, all work on the insulation of the well should be done in advance, before the onset of cold weather.

materials for borehole insulation

As already noted above, as a heat insulator you can use improvised materials. To do this, around the hole dig a hole to the depth of freezing ground, around the wellbore they construct a box, into which the chosen insulation is covered.

Thermal insulation material must be protected from moisture.

Artificial insulation is recommended to use in northern regions, where the earth can freeze to two meters, as well as in places of close groundwater occurrence.

Materials for the insulation of the well must be selected, guided by their cost and technical characteristics. Attention deserve: polystyrene, basalt and glass wool, polystyrene foam.

As you know, the air conducts heat very poorly. Therefore, between the casing of the well and the layer of thermal insulation it is necessary to leave an empty space, about 5 centimeters. The resulting air layer will reliably protect the well from freezing.

In modern insulating materials, the thermal insulation properties of air are used very widely. All foamed materials contain inside microscopic air bubbles, which ensure their high thermal insulation characteristics.

The works on the warming of the well are most often carried out in the following sequence:

The stand is covered with a fine steel mesh with an indentation from the walls of the pipe of 5 centimeters, after which a metal casing is put on the construction. Between the mesh and the casing leave room for a heater.

Under the valve you need to install a tray of galvanized sheet that will protrude beyond the casing, so that water does not get into the heater.

Warming of water supply system

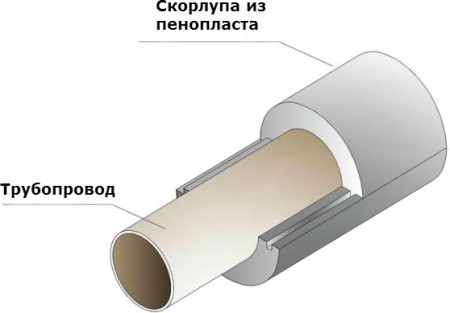

To insulate water pipes, most often use foam plastic, as an inexpensive and reliable thermal insulation material. Working with polystyrene is simple enough and convenient, it does not require any special skills. Being under the ground, the foam does not lose its thermal insulation characteristics, it can even be reused, for example, if the water pipe needs to be disassembled or repaired.

Mineral wool is a good heat insulator for water supply, but it costs several times more expensive than polystyrene. For pipes this heat insulator is sold in the form of cylinders made of basalt fiber. On top, they are covered with a protective layer of pergamene, roofing paper or foil.

Such a basalt cover is very tight to the pipes, the installation is done without the use of trays and additional protection.

Glass wool is a relatively cheap and effective heat insulator. Most often it is used for thermal insulation of plastic and metal-plastic pipes. With the help of glass wool, it is possible to make excellent warming of the water pipe in the country.

Glass-wool is simply wrapped in pipes and fastened with plastic tape. After that, arrange a waterproofing, which can be made from a roofing felt.

Cylinders made of basalt wool are mounted even easier and faster. Their halves are simply worn on a pipe with a slight offset to ensure overlap. Halves are fastened with scotch tape. To insulate pipes in places of turns and corners, special shaped "shells" are used, which fit tightly against the walls of the pipe.

Warming of the pumping station

Pumping station, which is not installed indoors, needs to be insulated. Negligent attitude to thermal insulation can lead to deformations of pipes and components of the water supply system, as well as to the complete failure of the electric pump.

It is quite difficult and expensive to repair a damaged pump station, and in some cases it is simply impossible.

how to insulate

As already mentioned, the pumping station is usually installed near the water source. Very often the hosts poorly trim the walls of the pit in which the station is located - for this, ordinary planks or bricks are used, only to protect the walls of the pit from the collapses of the ground.

The upper part of the pit is covered with a lid to protect it from precipitation. There are several ways to insulate the pump station qualitatively.

The first method is the simplest. It is necessary to excavate the pit below the freezing level of the soil. In this case, the owner does not bear any costs other than labor costs. But this method is suitable only for warm regions, and if the earth freezes below one meter in winter, additional thermal insulation is needed. There is another danger - the flooding of the pit by ground and meltwater.

The second method of insulation involves the use of a thermal insulator with good water-repellent properties. It can be polyurethane foam or foam foam. Mineral cotton wool will not work, as it absorbs water well.

Thermal insulation material is attached throughout the interior of the pit, including the lid.

insulation with polyurethane foam

The main advantage of this material is its universality. Polyurethane foam can be used to insulate almost any surface. The process of insulation of the pit is as follows.

To begin with, the bottom and walls of the pit are carefully leveled. Further in the pit a wooden frame is made, which is lined with plywood. The plywood is subsequently sprayed with a layer of polyurethane foam. All the work is carried out very quickly, since the polyurethane foam freezes almost instantaneously. As a result, a continuous seamless layer is obtained, which prevents cold and moisture from passing through.

The drawback of this method lies in the complexity of the application of the material. It is impossible to apply it manually. To buy equipment is very expensive, and it makes no sense. It remains only to hire him or hire a specialist. In this case, the cost of the insulation of the pit may be unreasonably high.

insulation with expanded polystyrene

Before fixing the material, the walls of the pit are also leveled. Plates of expanded polystyrene are fastened to the frame with the help of glue, additionally picking up plastic dowels - "fungi". The gaps between the plates are carefully blown out with a mounting foam. Additional protection from moisture is not needed - polystyrene foam repels water very well.

All the above procedures, if performed correctly, will reliably protect the pumping station from freezing, and the water supply will work without fail throughout the year.