Provide a comfortable temperature in the house or apartment, as well as get savings on fuel consumption in the winter time can be done by arranging a system of thermal insulation of the ceilings. Of course, this work will require some financial expenses, so that the result of the done becomes noticeable with the arrival of the winter, it will be necessary to analyze the available options for insulation, determine if it really is necessary to insulate the ceiling, and if necessary, what materials are best used for this.

Content

- 1 What materials can be used to insulate the ceiling of a residential building?

- 2 Insulation for the ceiling of the house mineral wool - the characteristics of the material

- 3 How to insulate the ceiling inside the house from the inside

- 4 We warm the ceiling of the house outside

- 5 What problems can occur after the insulation of the ceiling with mineral wool

What materials can be used to insulate the ceiling of a residential building?

First of all, it will be necessary to decide what exactly and how it will be warmed. For example, in cottages most often insulated mansard room - a layer of cipher or metal roofing can not keep the heat leaving the house. Insulation of the roof gives a double advantage - in winter, the heat-saving system will keep heat in the house, in the summer it will work in a different direction - it will not let heat pass under the roof, hence the house will be cooler.

If the attic of the house is uninhabited and cold, then the ceilings are exposed to the insulation. It should be remembered that the heat leakage through the ceiling can be about 30% of the total heat loss. Having insulated the house once, it is possible to get a significant reduction in heating costs over many years.

Since residents of the upper floors of the apartments often complain that when the hot batteries in the apartments are still cold, they should pay attention to the quality of the insulation layer, the so-called. powder in the attic. Since the attic space in the high-rise buildings is unheated and in most cases is open to all winds, experts recommend strongly to solve the problem of insulation of the flooring, it is possible to try to do this through utilities, you can do the work yourself, will be done faster and better - work for yourself will not want.

Do not interfere with the installation of a layer of insulation, in particular mineral wool, on the floor between any floors - the apartment will immediately become warmer, the noise from neighbors from above will hardly penetrate. Modern panels for floors practically do not have soundproofing properties.

As a thermal insulation material for ceilings, different materials can be used, such as:

- foamed polyethylene,

- foam and foam isole,

- eco-wool,

- mineral wool,

- expanded clay - for insulation from the attic.

On the need for insulation of ceilings and other house structures watch the video:

The leading position among them is minvat. To explain this is quite simple if you consider the requirements for heaters:

- environmental Safety,

- a low percentage of shrinkage during thermal exposure,

- resistance to fire,

- high thermal and sound insulation,

- the ability not to interfere with the natural processes of steam circulation,

- the structure of the material should not contribute to the spread of mold and rot, insects or rodents,

- long service life,

- simple installation.

All these requirements are met by minvats, in addition, it attracts consumers with low cost.

The main disadvantage of mineral wool is its ability to absorb moisture, which ultimately leads to a decrease in body insulation properties. Therefore, the technology of thermal insulation of ceilings with mineral wool should be observed.

More about the characteristics of mineral wool on video:

Insulation for the ceiling of the house mineral wool - the characteristics of the material

Among the characteristics that are important for a heater should be considered:

- Density, for mineral wool from 30-220 kg / cubic meter, it is recommended to insulate ceilings with cotton with a density of not less than 80 kg / cubic meter.

- The indicator of thermal conductivity determines the main quality of the material - its ability to retain heat. The lower the value, the higher the quality of the material. A ceiling wool insulation must have a coefficient of 0.036.

- The thickness of the mineral wool determines its resistance to high temperatures, with a decrease in thickness, the protective properties of the material decrease. The optimum thickness of mineral wool for insulation of the ceiling is 40 mm.

- Dimensions, for each brand of mineral wools are characterized by their size. Typically, the length of the roll is from 1000 to 1200 mm, width - from 500 to 600 mm.

Depending on the thickness, the mineral wool can be sold:

- in rolls (thickness up to 50 mm),

- mats made of mineral wool are also sold (thickness from 100 mm).

Storage of insulation must be carried out in a dry room, in a waterproof package.

When buying, inspect mats made of mineral wool - it is not recommended to buy soaked material - even after drying it will not restore its properties. If for the insulation of insignificant areas in small buildings minus wool cuttings are obtained, then it is undesirable to use material of different density in one sector. If the aim is to increase sound insulation, then the material can be used either.

How to insulate the ceiling inside the house from the inside

Mineral wool is one of the most acceptable options for insulation of ceilings in a private house. Usually for internal insulation, a tile material is used which, in combination with a gypsum board structure, can create an insurmountable barrier to the warm air rising to the ceiling.

The process of installing the heater is as follows. The first thing to do is lay a layer of waterproofing, it can be a glassine or waterproofing film.

The next stage is going to the frame, wooden or metal. Choose the material most often depending on financial possibilities. When assembling the frame, special construction tools will be required, but if you have some experience in performing construction work with the task, you can manage yourself.

If the frame is made of wood, then the bars are pretreated with antiseptics, even if they are in the room this procedure will be useful. Stuffed bars starting from the wall in which there is a window are placed parallel to this wall.

The distance between the batten rails should correspond to the width of the mats made of mineral wool (be smaller than the width of the mat by 1-2 cm). Since the insulation is soft, then it should be laid so that the entire distance between the crate was filled. The frame is fixed using dowel-nails.

Installation of insulation is to glue the material to the surface of the ceiling. For work it is possible to use glue intended for installation of a tile.

If necessary, the insulation is glued in two layers.

Since the mineral wool can absorb moisture and lose its properties, it is necessary to lay a layer of waterproofing on top of it.

Next, the thermal insulation system is plastered with plasterboard, PVC panels, or a board. Self-tapping screws are used to fix the finishing material. It is desirable to use fasteners made from hot steel - they are more durable and able to withstand significant loads.

Depending on the selected finishing material, the following steps are planned:

- for gypsum cardboard it should be 40 cm, the edges of adjacent bands of material must necessarily fall on one profile,

- if PVC panels are used, the step of the flooring can be equal to 60 cm, the profiles should be installed perpendicular to the panels.

Experts recommend that when laying mineral wool, avoid shrinking it - when squeezed, it may lose its heat-saving properties, because the air inside the material itself acts as an obstacle to heat exchange between the room and the attic.

On the principle of installing mineral wool materials, watch the video:

In the event that a decision is made to convert the attic into a residential building, it is necessary to perform the roof insulation, as a thermal insulation material, mineral wool can also be used.

We warm the ceiling of the house outside

This kind of insulation is used in the event that the ceiling in the house is in an ideal condition and breaking its finish is economically impractical. The second reason may be the reluctance of home owners to make the ceiling level lower. In such cases, the insulation of the ceiling with the mineral wool outside is made. insulation will be subject to the floor of the attic.

The process should begin with cleaning in the attic - it should be cleaned of unnecessary things, debris and dust.

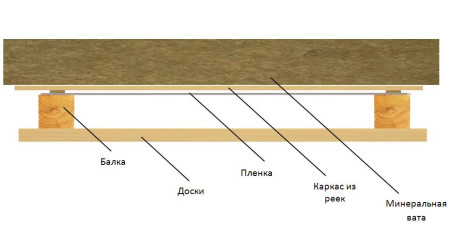

Next, a layer of vapor barrier film is laid on the ceiling overlap, the joints of the strips are glued together with building tape. Heat insulation is laid between the beams, while checking the thoroughness of the installation - cracks should not remain.

To create a more reliable thermal insulation system, practice laying the insulation in two layers. In this case, the joints in the first layer must necessarily overlap with mineral wool mats laid by the second layer.

You can cover the mineral wool with the simplest floor covering.

What problems can occur after the insulation of the ceiling with mineral wool

Sometimes it happens that after the ceiling has been warmed, the minivate corners of the rooms remain cold and permeable to the heat flows that rush towards the attic. The reason for this phenomenon is a metal frame that can not prevent the heat from leaving.

The second frequent problem is the too rapid burning of the backlight (spotlights). The appearance of this phenomenon is facilitated by the absence of an air gap between the luminaire and cotton wool. The absence of a normal air circulation causes the light bulb to burn out. Avoid the negative phenomenon will help the left air gaps around the fixtures.