For many years now linoleum remains the most demanded floor covering due to its unmatched appeal and durability, ease of installation and relative cheapness in comparison with other natural and synthetic finishing materials. A lot of design and color solutions, environmental safety and excellent performance characteristics make it possible to successfully apply linoleum for decoration of the floor space of residential and office premises.

At the same time, long-term operation is determined not only by the quality of the coating, but also by compliance with the laying technology - linoleum welding. About what is welding linoleum and how to put linoleum correctly we will tell in the article.

Welding of linoleum: basic methods

Despite the seemingly easy and banal laying of linoleum, this process can cause a lot of difficulties and difficulties, since it requires the presence of professional skills and special tools and the possession of styling technology. Undoubtedly, it is possible to produce the entire complex of floor coverings by yourself, however, it is necessary to take into account the features of the process.

So, experts distinguish two basic, fairly simple technologies for laying linoleum:

- no-glue way of laying,

- laying linoleum with gluing.

Glueless flooring technology, being the most elementary in terms of execution, is applicable in the case if the area of the room in which the floor covering works is carried out, no more than 20 square meters. m. For this, taking into account the allowance for fitting the picture, sheets of the desired size are cut out and laid on the floor surface. Reliability and stationarity of the coating will bring the fixing of the edges of the coating by welding and fixing the skirting boards.

Technology of laying linoleum with gluing is more complex and its use is preferable in those rooms where a greater load on the floor is expected. In this case the flooring of linoleum can be made by two methods:

1. linoleum is folded in half;

2. slides into roll "face" inward, processed by adhesive composition and rolled out. This laying is often used for finishing wooden or stone floors.

However, regardless of what type of linoleum you chose and on what technology you stopped, you will have to work on the sealing of seams. Not so long ago, nails and scotch were used in the residential premises to seal joints and seams between the cover sheets, today new technologies and high-tech materials for welding butt sections of floor coverings came to replace.

At the present stage, when laying linoleum in residential premises, the method of cold welding based on special adhesive compositions is successfully used, while in office and production areas the joints are sealed by the method of hot welding. This option is more complicated due to the use of special rods made of PVC and high-tech construction equipment.

On laying linoleum by cold welding, you can learn from the video on youtube.

Let us dwell in more detail on the technological features of the method of hot welding of linoleum.

Hot welding of linoleum

Just note that the hot method of joining joints and seams is used only in relation to commercial linoleum.

Unfortunately manufacturers of commercial linoleum produce a coating with a width of no more than 2 meters. And this is clearly not enough to finish the floor of public or industrial premises. There is only one way out - the connection of commercial linoleum panels by welding. A feature of commercial coverage is the possibility of using in rooms with increased traffic and a high daily load on the floor surface. Using the hot welding method, you practically turn 2 sheets into 1, ensure the stationarity and reliability of the coating.

tools for hot welding

Prepare tools and necessary consumables for hot welding. You will need:

- a special device for welding linoleum with nozzles, which is compact in size and is connected to a conventional power supply network;

- an arched knife;

- chisel chisel;

- welding cord.

welding process technology

Directly the process technology is quite simple and at the initial stages it is even similar to the method of cold welding of linoleum with only one difference - the glue is not used, instead the butt sections are welded using a special rod-rod made of plasticized PVC. Under the influence of high temperatures it melts and is firmly fixed in a narrow V-shaped groove of the joint. Thanks to the variety of color cords for brewing joints between linoleum panels, you can easily select the most suitable for your coating.

Before conducting hot welding specialists recommend to glue sheets of commercial linoleum to the floor surface, while ensuring the most dense bonding of the panels with each other. Minimize the number of gaps and cracks between the sheets, as they make the weld area uneven and even noticeable.

At the initial stage, using a slotted chisel, cut the grooves on the butt sections. The width of the groove should not be more than 2-3 mm, and the depth - no less than ⅔ of the thickness of the linoleum. Using a vacuum cleaner, carefully clean the grooves.

Prepare the cord. Cut the welding cord so that its length reaches ½ the length of the working seam. After warming up the industrial hair dryer to a temperature of 350-400 degrees, carefully thread the finished cord into it and proceed to welding.

recommendations for laying linoleum by welding

To get a good result you should follow the following recommendations.

1. First, force the end of the welding cord firmly into the joint of the linoleum panels. After about 1-2 seconds, move the dryer towards its handle.

2. Welding, monitor the location of the free end of the welding cord. It must be strictly parallel to the seam being processed.

3. The speed of the hair dryer is selected in such a way that when moving it melts the cord, leaving behind it a slight bump on the cover sheet.

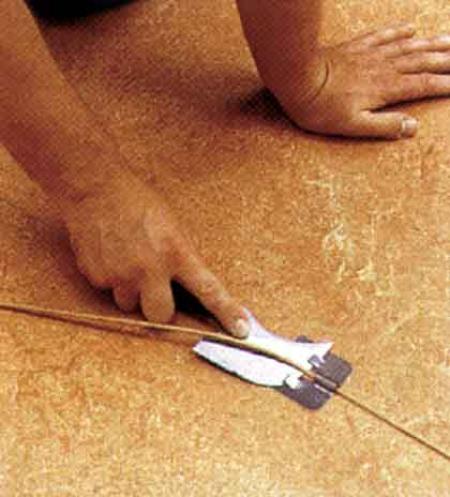

The formed tubercle is eliminated with the help of an arcuate knife immediately after welding. Do not wait until it cools down!

Similar actions are repeated on the opposite side of the seam with a mandatory overlap in the middle of the leaf at 2-3 cm. A completely cooled joint forms a build-up, which also needs to be removed by one motion of the knife along the entire length of the coating.

Remember, one-step removal of the weld on commercial linoleum can lead to jags or concavities!