Today we are talking about a unique floor covering of natural origin. And his name is the cork floor. And is not this the cork, you ask, which is clogged with expensive elite wines and glass thermos? Yes, yes, that's what we have in mind, and our conversation will be about it.

Content

From cork to flooring

Bung - this is one of the lightest coatings of natural origin, which due to its excellent performance and quality characteristics can not go unnoticed, and has been used extensively in rough and finish finishing activities for many years.

To get a cork with 25-20 year old tree, the bark is removed, in place of which cork grows for 10 years. Perfected for years, the technique and jewelry work is not only safe for natural wood, but also very useful. From the removed cork, using special technologies, cork slabs, a web that can be rolled up, or a granular coating used as a reliable and durable substrate for a laminate floor, cork or parquet boards are produced.

However, what kind of final form would not accept cork material, it attracts consumers with an attractive exterior and natural origin, lightness and ecological safety, water and water resistance, excellent sound and heat insulation characteristics, long service life and many other inherent properties.

Classification of cork cover

The most expensive type of finishing material - cork plywood - are obtained from a solid mirror coating, carefully removed from the oak. As another method of manufacturing, pressurization of cork sheets under the influence of high temperatures is advocated and formation agglomerate. Here in the course are pieces of different quality and size. And, finally, a composite combination of large veneer and agglomerate. This is the most compromise option, combining both large-sized veneer, and its smaller elements.

Regardless of the method of obtaining a cork coating, its quality is always faultless, and the difference is only in value due to external differences.

Depending on the device and the method of flooring, the following classification of the cork flooring is distinguished:

- Lock, according to the principle resembling a method of laying a laminate or a parquet: panels made by the type of puff cake (cork layer, interlayer, resistant to moisture, again cork and completes the "cake" paint coating) are connected by combining one part to another.

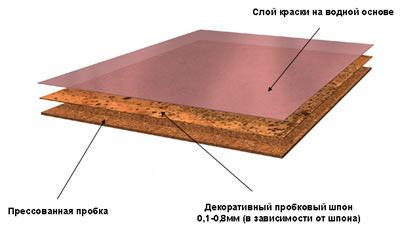

- Adhesive appearance is a durable cork coating consisting of individual tiles 4-6 mm thick, outwardly reminiscent of ceramic or tile. Their fixation is carried out with the help of adhesive composition. Each individual tile is the same "puff cake", however, the agglomerate acts as the lowest layer, and cork veneer is used as the top layer. It is he who is responsible for the attractiveness of the appearance and the unusual texture of the flooring. Such a tile is covered with varnish already independently after its installation on the prepared base.

Among the advantages of such a floor covering from a cork, first of all, standard sizes are allocated: 300 × 300, 450 × 150, 600 × 300, 450 × 450 mm, allowing to lay on the floor surface absolutely any pattern and pattern. This kind of coating is considered to be the most resistant to moisture and can be successfully placed in rooms with high humidity.

In addition, we can distinguish floating cork floor, so-called parquet, is a coating, a glued foundation of MDF. The dimensions of the panels reach 900 × 185 mm, and because of MDF, such a cork floor is very susceptible to moisture and water.

And, finally, cork technical It plays the role of a substrate for the base of the floor surface, it also covers the voids that are formed by the floor and wall. Perfectly copes with the tasks of heat and sound insulation of the floor.

Pros and cons of the floor from cork wicanders

First of all, I would like to note that the floor covering made of cork is environmentally friendly and safe for the health and life of all household members. A unique porous structure provides good air exchange and absorbs noise, which is very important in multi-storey buildings. Soft to the touch, the floor under the feet slightly springs, does not rot and is not affected by bark beetles.

So, among other advantages, in our opinion, we can distinguish:

- Natural origin, and hence, absolute environmental safety.

- Hypoallergenic and no risk of asthma.

- Elasticity of the cork floor and the ability to restore the original shape due to structural features.

- Excellent abrasion resistance. Especially happy women of fashion who prefer high and thin studs: heels do not leave scratches and do not spoil the appearance of the cork floor.

- High level of sound absorption: the cork is a natural soundproofing device, which significantly reduces the vibration and vibration of sound waves in any premises.

- High thermal insulation properties: it's nice to walk on such a surface barefoot. Cork is an excellent alternative to a warm electric floor.

- Lack of slip. A sufficiently high coefficient of friction (0.4) makes the floor non-slip, even if the surface is glossy.

- Thanks to anti-static cork floor is indispensable in offices and computer rooms.

- Wear resistance and durability. Since the cork retains its properties for 100 years, therefore, the service life of the floor covering made of it is practically unlimited. The only factor that can damage the appearance of the coating, can be the use of abrasive products and substances, such as sand. But if you do not walk on the cork floor in street shoes, then it will please not only you, but your grandchildren.

We will also talk about lack of cork. They are few, and the main one is a rather high price. In addition, the cork - the material is soft, and therefore, can remain on the surface of the dent from the furniture that has stood on one place for years. The varnish coating may wear off with time, so sooner or later it will be necessary to apply the varnish again, however, it should be noted that parquet boards need to be cycled and restored.

Cork floor installation technology

Laying the floor of the cork, as well as the rest of the coatings, is preceded by the stage of leveling the base. If there are significant differences in height, then you should make a cement screed. If a substrate is needed, it is better to use polyethylene or polypropylene. Locking-type panels must be assembled in several rows, then the rows must be fastened with a "spike-groove". Between a wall and a floor covering it is necessary to leave a small backlash in case the plug will expand.

To fix the glued cork floor, a special glue is used, which so quickly seizes that the planted tile can not be moved after fractions of a second. Therefore, our recommendations: pre-lay the cork slabs on the floor, determine the most suitable arrangement, use a stretched twine to check how perfectly you aligned the rows. And only after that you can proceed to gluing to the floor surface. The glue has a rather sharp smell, so in the room you should arrange a through ventilation, and you can walk on the finished floor after 2 days.

More information about the technology of laying the cork floor on glue you can find out from the video on youtube.