Most car owners sooner or later think about building a garage for their vehicle. Someone builds a garage in advance, even before buying a car, someone is convinced of the need to build a "home" for their car, being already a car enthusiast with experience. A car is necessary for a car - no one will argue with this.

Content

There are, of course, some alternative possibilities for storing cars like paid indoor parking lots, but they will not solve the problem - firstly, it's expensive from a financial point of view, and secondly - parking, it's parking - you can not change oil, you can not get under the car , it just stands in a foreign territory and you pay for it. Of course, not all car owners can afford to build a capital warm garage with a viewing pit. This is a long, expensive, will have to hire builders and equipment. But to refuse to build a garage due to the fact that there is not enough money for a monolithic foundation, a brick and payment for the work of the builders is not worth it. Moreover, there are enough options. One of the simplest, relatively inexpensive and yet worthy options is to build a garage from the metal profile with your own hands.

Garage from metal: pros and cons

- The first and most important advantage is the relative cheapness and simplicity of the design. The garage can be built independently with one or two assistants within a few days.

- The service life of such a garage is about 30 years - not bad for such a quickly erect and inexpensive building.

- The garage from the metal profile does not need any decoration, it looks aesthetically pleasing and attractive.

But, alas, this garage will not provide sufficient security for your car, since the locks are easily cut off from it, and the walls of a thin steel sheet can not be easily opened. And if such a garage is not located in a private area or not in a protected area, then you will have to take care of installing alarms and other additional means of protection against thieves.

A disadvantage is also the poor protection of the structure from temperature changes. However, this shortcoming can easily be eliminated by insulating the garage. How to do it, and what materials to use - about this below.

A few tips for choosing a place for a garage on the backyard

It is not necessary to treat the choice of a place for a garage lightly - suddenly on a site chosen by you in the future it will be better to look at the gazebo, or the place will be better for some kind of farm building. One of the main requirements - the departure of the car should not interfere with anything. Ideal option can be considered the location of the garage so that its gate is on the same line with the fence. This ensures that the car leaves the street.

Well, if you can attach a garage from the metal profile to some of the buildings on the site. So you can save on building one wall. But do not build a garage to the apartment building, so as not to disturb the household with the sounds of the engine running and the smell of fuel and lubricants.

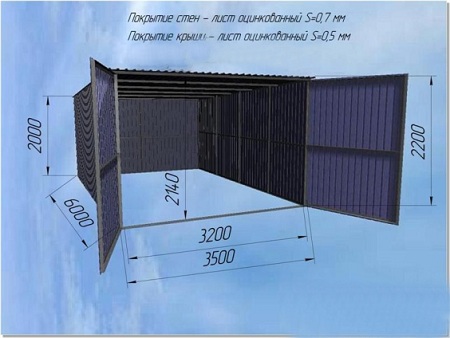

Garage of metal profile: drawings

Garage drawing 0 requirement is optional, but it is desirable to make it, especially the drawing is useful to people without serious experience of construction work. In addition, with the help of the drawing it is not difficult to calculate the necessary quantity of building materials and make an estimate.

Below we present several variants of drawings for the garage from the metal profile, which can be used both in the finished form and used as a basis for your project.

Choosing a metal profile for the garage

To build a garage, you will need a metal profile of PS or C - which means "wall". The figures in the marking indicate the height of the profile wave in millimeters. For example, "PS 30" is a wall profile with a wave height of 30 millimeters. The higher the wave height, the tougher the profile sheet, and the price, respectively, is higher. Do not try to save money and buy a cheap profile of the brand C 8 or C 10. It must be very carefully attached to the frame, so that the sheets do not "walk", and the integrity of the construction is broken, and the thin sheet with a fresh wind will still vibrate. The thickness of the corrugated sheet is usually 0.4 to 1 mm. For the garage will be enough 0.5 mm.

In addition, in fact, corrugated board, you will need:

- Reinforcement and concrete solution for foundation pouring.

- Rolled metal: corner, profile or round pipes for frame and gates. Wooden bars.

- Self-tapping screws for metal.

Of the tools:

- Bulgarian, circles on metal.

- Welding machine.

- Screwdriver or drill.

- Scissors for metal or electric jigsaw for cutting profiles (in the absence of a small Bulgarian)

How to build a garage from a metal profile: the stages of construction work

Foundation of the foundation. It is most preferable to make a foundation for a garage in the form of a monolithic slab, which will also serve as a floor in the room. The work itself is uncomplicated, it is quite possible to manage over the weekend, but it will be necessary to wait for the full hardening of the concrete for about three weeks.

- Mounting the frame. The construction is made of rolled metal: a channel, pipes and corners. In this case, vertical racks are installed at the stage of foundation pouring. All other parts are welded. The period of installation of the frame is 2-3 days.

- Installation of sheets of corrugated board. Nothing complicated: the sheets are cut with a jigsaw, scissors or a Bulgarian, after which fasten to the frame with metal screws or aluminum rivets.

- The work takes a maximum of two days with the participation of two or three people.

- Installation of the garage gate. The frame of the gate is welded from metal corners or a channel, and is lined with a metal profile. The work takes no more than two days.

foundation

The first stage of construction works. After pouring, you can not wait until the concrete is completely solidified, and immediately proceed to solve other problems.

First, mark the area under the garage, remove the soil layer to a depth of up to half a meter. The bottom of the pit is sprinkled with clean sand, and the sand is abundantly moistened. After that, grooves are prepared for the vertical racks of the frame. By the way, wells for racks filled with strong concrete will play the role of foundation piles, which will significantly increase its resistance to winter puddling of the soil. The depth of the wells is 50-70 cm. Next, along the perimeter of the foundation pit, a wooden formwork is installed.

The bars of the reinforcement with a cross section of 8-12 mm are laid in 20 cm increments along and across the excavation, and the reinforcement net is connected with a knitting wire. In this case, you can use a special hook or ordinary pliers.

How to tie the armature, you can learn from the following video:

Racks are installed in the wells, the lower part of which must be pretreated with bituminous mastic. The stands are set strictly on the level and fastened with spacers. After that, a layer of concrete is poured and leveled by the rule.

the frame of the gates and the garage

While the concrete is getting stiff and gaining strength, it is possible to assemble the frame. You can make it from a metal corner or profile, or from wooden bars. To fix the bars to the vertical posts, steel plates with holes are welded.

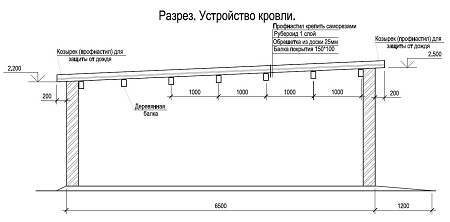

At the beginning of the work cut the material of the required length. Next, horizontal bars are welded on three sides of the frame. The roof of the garage from the metal profile is easiest to make a one-run, with a slope to the rear wall. This is the simplest variant: horizontal rails are welded to opposite racks, on which a wooden crate is installed. It should be noted that if in the winter a lot of snow falls, the crate must be made solid, or a gable roof should be built.

The frame for garage doors is welded from a metal corner. The material is cut at an angle of 45 degrees, the carcass is welded, and then the metal corners are welded at the corners of the frame for additional rigidity. In those places where there will be locks and bolts, weld metal plates.

The hinges are welded to the front pillars of the frame, after which the finished frame of the gate is inserted and the spaces for the hinges are marked on it. When it is supposed to make the garage door non-removable, the loops are welded together in such a way that they can not be removed.

installation of sheet metal profiles

Garment frame can only be trimmed after the concrete has completely solidified. This is necessary in order not to disturb the vertical racks of the frame and prevent damage and deformation of the profile sheets. The sheets need to be fixed vertically to ensure unhindered flow of water through the walls. The material is lapped into one wave, and this must be taken into account when calculating the amount of material.

It is much more convenient to order already cut sheets - this will save time and prolong the service life of the metal profile, as the factory cuts a slice of zinc and paint.

Garage begins to sheathe from the walls. The first sheet is installed in such a way that it closes as close as possible to the bottom edge of the wave to the rack, this will help to avoid injury during operation.

Sheets of metal profiles are fastened to the carcass with self-tapping screws for metal and rubber gasket with a screwdriver or electric drill.

First of all, the upper corner is attached, then the entire sheet along the perimeter, except for the place where the sheets meet. Next, overlap the next sheet overlap in one wave, twist the screws at the junction, then fix the metal profile in the remaining places. Thus, the walls of the garage are completely lined. During the installation of the metal profile it is necessary to follow, the upper corners of the sheets are firmly attached to the vertical posts.

Work on the installation of the roof begins with the installation of planks and gutter. First of all, hooks are installed for gutters and gutters. Throughout the perimeter of the roof, a windshield is attached, which is a steel sheet bent at an angle of 90 degrees. Its purpose is to prevent precipitation from falling under the roof. On the lower edge of the roof, the wind bar is set so that it falls into the gutter.

On the roof skeleton metal profiles sheets are mounted along the axis of the garage to ensure a drainage. From above, a sheet of corrugated sheet is installed on the wind bar and aligned along the edge of the roof, after which the wind bar is attached additionally with screws to the wooden crate.

Warming of garage from a metal profile

Well, that's all, your garage from the metal profile is almost ready. But if you are going to keep the car in it all year round, the room must be insulated. Doing this is necessary not so much to ensure your own comfort, but in order to protect the car from the effects of temperature changes. But do not be too zealous and create inside the garage in the winter room temperature. Best of all, if in winter the temperature inside the garage will be from -1 to -5 degrees Celsius. If you maintain a high temperature in the garage, this is very unfavorable for car aggregates - if in the street -25 and in the garage is +20, then leaving the warm garage, you expose your car to a sharp temperature drop, which can damage its parts and components.

It is best to insulate the garage immediately in the process of construction, although the insulation of an already operated garage does not represent any problem.

Choosing a heater for the garage of corrugated board

In our case, the most popular heaters are:

- Materials based on mineral fiber. Are sold in rolls or plates.

- Styrofoam in slabs.

- Polyurethane foam is liquid.

All these materials have both pluses and minuses.

expanded polystyrene

The most simple and inexpensive option. Plates of expanded polystyrene are glued directly onto the metal profile, then leveled with building mixtures. From the disadvantages of this method of insulation - the plates do not withstand mechanical stresses, easily ignite, and can also begin to decompose into intense heat and at the same time release toxic substances.

mineral fiber plates

It is best for a garage of metal profile as a heater suitable semi-rigid slabs of basalt fiber. This material has very good thermal insulation characteristics, it is completely ecological and does not burn, which is very important for the room in which the car is contained. The melting point of this material exceeds 1000 degrees Celsius.

The only serious drawback of basalt fiber slabs is the ability to absorb water, so when installing it, leave a ventilation gap of a few millimeters. Circulating air removes excess moisture from the heat insulator and prevents the formation of condensate on the inside of the metal profile sheets. Plates of insulation are installed in a frame of U-shaped profiles, attached to the wall.

If the insulation works are carried out during the construction of the garage, the thermal insulation is better to install on a special thermoprofile, which prevents the formation of cold bridges.

liquid polyurethane foam

Not the cheapest, but very convenient and effective technology of insulation of premises. The heat insulator is applied by a continuous layer to the surface of the wall, and there are no seams and cracks left. Liquid polyurethane foam, in addition to insulation, is also used as a noise, hydro and vapor barrier, while protecting the metal from rust. Polyurethane foam is durable, its service life is not less than forty years.

As for the insulation of the garage roof from the metal profile, all the above thermal insulation materials are suitable for this purpose. With the warming of a simple saddle roof problems should arise. If a mineral fiber plate is used as a heat insulator for a roof, the insulation layer must necessarily be covered with a light finishing material, plywood or fiberboard can be used.

As you can see, in the construction of a garage from a metal profile there is nothing complicated and all the work except, perhaps, welding, can be done on their own, while saving time and money. But if there is neither the desire nor the opportunity to independently engage in construction work, you can buy a ready garage from a metal profile, the price of which varies depending on the size. So, the garage size of 3x4 meters will cost about 55 000 rubles, 3.5 x 5 meters - 70 000, and 4x8 meters - 135 000 rubles.