The foundation of the house is its foundation, on which the life of the entire building depends to a large extent. The foundation is subject to constant loads and aggressive influence of ground, rain, thawed and capillary waters, as a result of which it can gradually deform and collapse. Concrete is very good at absorbing and retaining moisture. Gradually climbing up the capillaries, water gradually falls inside the walls and floor, providing excellent conditions for the emergence and reproduction of many species of fungi and mold.

But this is not the main danger. More serious is the problem of protecting foundations in a continental climate, where every year several times the water freezes and melts. If the moisture gets inside the concrete foundation and freezes there, the concrete will begin to break down.

To protect the foundation of the house from the destructive effects of moisture, it is necessary to make timely and high-quality waterproofing. Waterproofing works must be carried out at the stage of foundation construction. And let the apparent fortress of the reinforced concrete structure does not lead you astray, the well-known saying "the water grinds the stone" is very relevant here.

Remember that repairing and rebuilding a damaged foundation will cost significantly more, and that's not mentioning the complexity and laboriousness of repair work.

Content

Technology of waterproofing the foundation

The foundation requires attention and accuracy at all stages of the work, beginning with calculations and laying the foundation, and ending with the work on waterproofing and warming.

It can not be said that the waterproofing of the foundation is simple, since the technology itself requires a certain level of knowledge and an elementary understanding of the processes that take place in the concrete itself and surrounding soil. It is also necessary to know the properties of these or other waterproofing materials. Of considerable importance is the relevant experience, so before starting work it is highly advisable to consult with specialists and take their recommendations into consideration.

Before you begin work on the waterproofing of the foundation, you need to consider a few very important points:

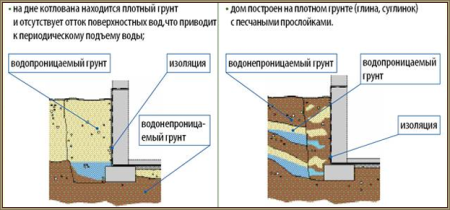

- Ground water level.

- Force of swelling of the soil.

- Soil composition.

- The conditions under which the construction will be operated.

If the groundwater lies below the base of the basement by more than one meter, then there will be enough vertical coating waterproofing and horizontal, using an inexpensive roofing material.

In the case where the level of groundwater is less than one meter from the basement foundation, but rarely or never reaches the basement, then a wider complex of waterproofing works is needed. So, the horizontal waterproofing will have to be done in several layers, each of which must be carefully processed with mastic.

For vertical insulation in this case, a single coating will not be enough, it is also necessary to use bonding materials. If the budget allows, it is possible to additionally treat the foundation and the basement with penetrating waterproofing, which prevents the movement of water through the capillaries.

If the groundwater lies above the basement and there is a real threat of flooding the basement, or in the area where the construction work is going on frequent and heavy rains, then in addition to the above measures it will be necessary to install a drainage system around the entire building.

The cost of waterproofing works will depend on the area of the surfaces being treated, on the quantity and on what materials for the waterproofing will be used. The most budgetary option is the treatment of the foundation surface with bitumen. The most expensive is a complex waterproofing with coating, roll and penetrating materials plus the installation of a drainage system or a pressure wall.

Waterproofing the foundation, types of waterproofing. Horizontal waterproofing of the foundation

For concrete belt and solid monolithic bases, horizontal waterproofing is done in several places:

- At the floor level of the basement or below the level of 15-20 centimeters.

- At the junction of the foundation with the walls and in the basement.

It should be noted that the horizontal waterproofing is done only during the construction of the house, so all work must be planned in advance.

Before beginning the arrangement of the foundation, a layer of fatty clay approximately 30 centimeters thick with a subsequent ramming is covered at the bottom of the finished pit, after which a layer of concrete about 5-10 centimeters is poured on top. This is necessary for waterproofing under the foundation. The layer of waterproofing is laid only after complete drying of the concrete - not less than two weeks. On dry and settled concrete, the mastic is applied to the foundation, then the first layer of roofing material is laid. Mastic is also applied to the roofing material and the second layer is laid. Next, the top is again poured concrete 5-7 centimeters thick, which is carefully leveled and ironed.

Iron-casting is not a prerequisite for ensuring a good waterproofing of the foundation, but it will not be superfluous. The concrete is fermented as follows: 2-3 hours after the concrete solution is poured, dry cement is poured onto its surface with a layer of several centimeters and is leveled. After a while, cement is impregnated with moisture from concrete. After that, the surface is damped with water from time to time until the screed gets strength and completely hardens.

At the end of work with the foundation, it must also be waterproofed so that moisture does not fall into the walls. This is done simply: the surface of the foundation on which the masonry will be made, is thoroughly impregnated with bituminous mastic, several layers of roofing material or other material are spread on top. Speakers beyond the edge of the foundation edge of the material do not need to be cut off - they are bent downwards and pressed with a vertical waterproofing of the foundation.

Drainage system

The drainage system is necessary in order to remove excess groundwater or precipitation in a timely manner and prevent the flooding of the basement of the building. With the help of drainage system, water is taken to a special well.

To arrange the drainage, dig a trench along the entire perimeter of the building, retreating from it about a meter. The depth of the trench directly depends on the level of groundwater table. The width of the trench must be at least 30 centimeters. In addition, trenches should be digged with a slight inclination towards the well, where water will be collected. At the bottom lay geotextiles, the edges of which are wrapped around the edges of the trench by about 70-80 centimeters. Then perforated pipes for the garage are laid on the bottom, observing a slope of at least 0.5 centimeter per meter.

After that, a layer of washed gravel about 30 centimeters thick is poured onto the pipes. All this is wrapped in geotextiles and covered with a layer of earth. The ends of the pipes are taken out into the accumulating well. The drainage system can be made after the completion of construction or even during the operation of the finished building, if suddenly there is such a need.

Vertical waterproofing of the foundation. Waterproofing materials

To isolate the vertical surfaces of the foundation, different materials are used, including in complex with each other. Of the options that will be offered below, you can choose one or several, depending on the need.

bitumen waterproofing of the foundation

The cheapest and easiest option is using bitumen mastic or resin. For this purpose, bitumen is bought in bars, a used machine oil is poured into a container of suitable size (about a third of the volume). After that, the container is filled with small pieces of bitumen.

The container is heated in any accessible way. As soon as the bitumen melts to liquid state, it is applied to a previously cleaned surface. You can apply bitumen with a brush or roller, it needs to be smeared very carefully. Work starts from the bottom of the foundation, and ends at a height of 20-25 centimeters above the ground surface. Bitumen is applied in two or three layers, the total thickness should be at least 3 centimeters. The container with bitumen must be reheated periodically to keep the resin in a liquid state.

Bitumen penetrates rather well and fills all cavities and pores of concrete, protecting the foundation from moisture. However, the life of the bitumen waterproofing is not very large. To increase it, bitumen-polymer mastics are used, which are much more durable, and are more convenient to work with.

The modern market of building materials offers mastics of cold and hot application and polymer solutions of a rigid and liquid consistency. Such materials can be applied with a spatula, roller, brush or spray.

roll waterproofing. technonikol

Rolled pasting materials can be used alone or in combination with coating waterproofing. One of the most common and cheap materials is ruberoid.

Before sticking on the surface of the roofing material, it is preliminarily covered with a layer of bitumen primer or mastic - as described above. After that, the roofing cloth is heated with a gas torch and pressed firmly against the insulated surface. This method is known as the melting of roofing material. But besides this, it is also possible to use various adhesive mastics without heating the web. After the first layer is glued, a mastic is applied to its surface and a second layer of material is immediately glued.

Important point: the edges of the horizontal waterproofing before the fusing of the roofing material are wrapped downwards and tightly pressed against the foundation. The roofing material is deposited on top.

Recently, developers prefer more modern analogues of roofing materials, which include: Technonikol, Glass-Isolated, Rubitex, etc. All of them are produced on a polymer base, which gives the material elasticity, strength and wear resistance, and also significantly improves performance.

These materials are naturally worth a bit more than a common roofing material, but professional builders strongly recommend using them. However, without the use of mastic, the web material is not capable of providing sufficient protection.

liquid foundation waterproofing

Liquid rubber - a great alternative to the pasting materials. It has very good adhesion to the surface, is durable and resistant to high temperatures. And, most importantly - liquid rubber creates a completely hermetic seamless coating of the entire treated area. If the work on applying liquid rubber is supposed to be carried out independently, then in this case one-component rubber, for example, Elastomix or Elastoplaz, is quite suitable. For one square meter of the area, the material consumption is about 3 to 3.5 kilograms. Elastoplaz is applied in two layers, with each drying for 24 hours at a temperature of + 20 C. It is realized in buckets of 18 kilograms, costs a little less than Elastomix. If the remainder of the rubber remains in the bucket, the container can be tightly closed and used later.

Elastomix is applied in one layer, drying it takes no more than 2 hours at a temperature of +15 C. The material is implemented in buckets weighing 10 kilograms. If all the mixture from the bucket was not used, the residues should be disposed of, since they will solidify within a few hours.

Before the application of rubber, the surface is cleaned of dust and treated with a primer. After that, the mixture is applied with a roller, spatula or brush according to the instructions given on the package. Which of the above brands of rubber to choose depends on the preferences and financial capabilities of the builder, as well as on the time frame set for the implementation of waterproofing works.

For a surface treated with liquid rubber, additional protection may be necessary, if stones or construction debris are found in the soil for backfilling. The foundation is covered with a layer of geotextile or a pressure wall is made.

penetrating waterproofing of the foundation

Under this name, materials are realized that can penetrate into the concrete to a depth of 10-20 centimeters and solidify, forming microscopic crystals. This protection is good for preventing the penetration of water into the concrete through the capillaries. At the same time, the frost resistance of concrete is also significantly increased and its corrosion is prevented.

In the domestic market, such brands of penetrating waterproofing as Penetron, Hydrotex and Aquatron-6 are realized. All of them differ in cost, depth of penetration and method of applying the mixture. In the overwhelming majority of cases, these materials are used for the processing of foundations, cellars, as well as basement floors of buildings. Penetrating waterproofing is best applied to a damp surface. The solution is applied several times. Once it is completely absorbed, the outer film can be removed if desired.

plaster foundation waterproofing

It is applied simultaneously for waterproofing and leveling the foundation surface. In this case, special plaster mixtures are used, which include moisture-resistant elements: hydroconcrete, asphalt mastic, or polymer concrete.

The technology of applying the mixture does not differ from the plastering of the walls. After the plaster layer has completely dried, it is protected with a clay lock and backfilled with clay.

screen waterproofing of the foundation

This method is an improved alternative to a clay castle. In this case, special bentonite mats made on the basis of clay are used. Mats are attached to the previously leveled and cleaned foundation surface with dowels. Mats are fastened with an overlap of 10-15 centimeters.

After that a pressure wall is made next to it, which will not allow the mats to swell. Over time, the paper in the mats is destroyed, and the clay adheres and is pressed into the surface of the foundation, thus fulfilling the role of the waterproofing agent.

clay lock

In this case, along the perimeter of the foundation, a trench is dug about half a meter deep. At the bottom pour a layer of rubble. The bottom and walls of the trench are rammed with a thick clay in several layers. Each layer must be dried. The space that remains after the ramming with clay is covered with crushed stone, and the blind area is made from above. Thus, clay on the walls of the trench will not allow moisture to the foundation, its surpluses will go down through the layer of rubble.

Finally, I would like to note that the waterproofing of the foundation is a very important matter, and within the framework of this publication we briefly reviewed the main methods and materials. If you want to do all the waterproofing work yourself, you need to remember that one of the main points is the right selection of materials and a set of activities. Then the foundation of your house, without any doubt, will last a long time and will not require any repairs.