To build a house on your own countryside site of building materials today there is a lot, it is aerated concrete and foam concrete, natural wood, etc., but still, not the last place in this variety is brick. Buying it, future homeowners are often guided by its long life, its profitability and convenience. Choosing a brick, buyers are confident that the house of this building material will serve more than one generation. The total cost of a house from such a material will be quite large, but after a certain time, the costs will be covered.

Content

Pros and cons of brickwork

The masonry made of bricks has almost no flaws. The main disadvantage of this masonry is the poor heat retention. A five-centimeter brick wall can not properly guarantee good thermal insulation. Having familiarized with all the above information, you can easily answer the question: is it necessary to insulate the brick house. Specialists unanimously assert what is needed, both from the outside and from within.

External insulation of walls not only allows to preserve the useful area of the room, it creates protection for the wall itself, protecting it from the influence of the temperature effects of the external environment and prevents the possibility of its freezing. If the internal thermal insulation can reduce the heat loss inside the room, then the thickness of the wall at the same time under freezing temperatures freezes, as before the insulation. The dew point is shifted towards the boundary between the inner surface of the wall and the layer of insulation, this is where the condensation of the vapor occurs. It is known that such a place is an ideal environment for the development of fungi and mold. In addition, because of the increased humidity, there is an increase in the cooling of the wall.

How to insulate a brick house outside

To date, the market for building materials there are many types of insulation. After acquainting with them and consulting with specialists, you can choose the most suitable one from which the external thermal insulation of the brick structure will be made. Most often, thinking about what to insulate the facade of a brick house come to the conclusion that it is mineral wool, expanded clay, slag, expanded polystyrene, foam and others. For each of the listed materials for insulation there is a method of stacking and fixing. In addition, each layer after laying is covered with a trim. Produce it to create a beautiful appearance, as well as to create a barrier that will protect the design from penetration and the effects of moisture. In the form of the main material for finishing you can apply plaster, facing brick, decorative panels, thermo panels. We advise you to buy a tile for the blind area here, not forgetting about the harmony of the appearance of the building and the design of the neighborhood.

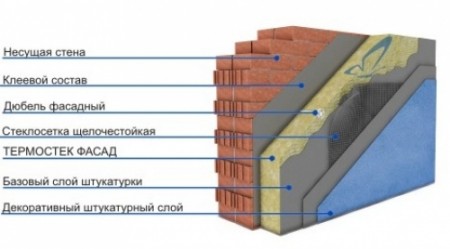

External insulation of walls from a brick by each of heat-insulating materials is made differently. For example, the most profitable insulation is made with mineral wool. Its use in the form of a heater can occur both outside and inside the house. Before the beginning of warming of brick walls it is necessary to make a lattice from reliable metal profiles or wooden racks.

The workflow with this type of insulation is as follows:

- measurement of the length and width of sheets of mineral wool;

- fasteners of carcass, wooden or metal, using dowels;

- laying of mineral wool;

- creation of a facing layer.

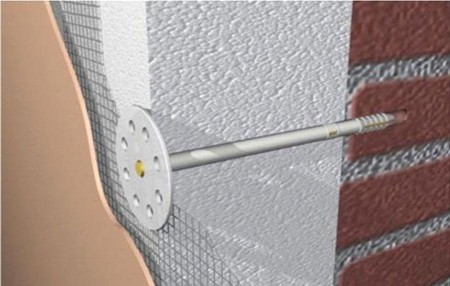

It is also good to make the insulation of a brick wall with the help of a foam plastic. It is famous for its good thermal insulation properties and high moisture-proof qualities.

It is convenient to fasten the foam with fixing elements and adhesives. Before applying the glue on the surface of the heat insulator it is necessary to hold a roller with needles. This procedure, will guarantee the necessary for the best adhesion, unevenness. It should be noted that the foam and its analogs must be attached only to an even surface. When there are sharp changes in the heat-insulated area, the foam does not glue, but is nailed. In such cases, only in this way it is possible to achieve a strong and qualitative fixation.

The working process for gluing this material is as follows:

- cleaning of the insulated area from dust, dirt and its subsequent priming;

- mounting the slats in the bottom of the wall, which will allow you to control the horizontal and evenness of the layers of the insulation;

- fastening of racks under the certain thickness and width of a heater;

- location of the adhesive on the sheet of insulation material at its center and perimeter;

- gluing foam to the surface to be insulated;

- performance of lining works.

The working process for injecting foam is as follows:

- cleaning of the surface from contamination;

- mounting the vapor barrier layer;

- fastening rail at the bottom of the wall;

- stowing in heat insulation material;

- nylon fastening with large hats;

- sealing of joints with foam;

- application of plaster layer;

- performance of facing works.

The qualitative performance of the work on the production of thermal insulation from the outside, provides for a good sealing of all kinds of gaps and gaps. Do not remain without proper attention to the openings of doors and windows. As a filler for slots, it is possible to use not the foam plastic format, glass wool and the like materials.

Among the builders, the material is also very popular. expanded clay. He occupies one of the first places in the list of loose heaters. The method of insulation with this material is used during wall masonry. They fill the space between two brickwork. The distance between the clutches should not be more than 8 centimeters.

Loose material, in any case, will eventually shrink. Therefore, experts advise in the space between the walls to make the so-called "shelves", into which the material will be emptied. Such "shelves" should be placed vertically, at different levels, in a chaotic order. Do such "shelves" of concrete or brick.

How to insulate a brick house inside

Only with the combined approach to resolving issues on the insulation of housing, you can achieve high results and fruitful work done. First of all, it is necessary to determine what kind of material is needed to perform warming inside the house. Of course, such a material must be distinguished by its good thermal insulation properties. And since the insulation is made from the inside and touches the useful space, the material chosen should be of a small thickness. Warming should be done without "theft" of the living space.

The specialists made calculations, according to the results of which it became clear that the thickness of the wall, without external and internal insulation, should be about 2 meters thick. Walls of this thickness can ensure the safety of heat in the house. Naturally, a house with such walls will cost insanely expensive. Therefore, it makes sense to make the insulation of brick walls. It should also be noted that internal insulation is only done when there is no possibility of making the insulation from the outside.

Mainly use three ways for internal insulation, with the help of:

- polystyrene foam

- plasters

- mineral wool.

how to insulate the walls of a brick house from inside with plaster

First of all, the following conditions must be observed without fail:

- stretched reinforcing fabric mesh on which a solution is applied;

- applying a minimum of three layers of plaster.

The first liquid layer of plaster is poured so that all gaps and slots are filled with building material. Such an insulating layer in thickness should be about 1 centimeter.

The next layer is made a primer. The thickness of it should be from 5 to 6 cm. Apply a primer in several approaches, that is, it is placed in several layers.

The third layer is applied in a thickness of 0.5 cm, with a solution. This layer bears an aesthetic load, so it must be done accurately, smoothly, accurately. It will make the surface of the wall level and hide all the flaws and irregularities.

how to properly insulate a brick house from inside with polystyrene foam

Polyfoam is not an expensive building material that is not very popular in this field, but also other materials, which have their advantages and disadvantages described above. The process of using it for insulation is as follows:

- preparation of a heat-insulated wall for the installation of this material;

- plastering to obtain a flat surface;

- mounting of waterproofing layer;

- fixation of foam plastic with special glue (glue is applied to the wall, sheets of foam are placed in the joint, without cracks and gaps);

- a layer of vapor barrier material;

- work on the finish (the last layer can be made by lining, sheets of plasterboard, decorative panels - it all depends on the desires and capabilities of home owners).

how best to insulate a brick house from inside with mineral wool

Mineral wool - a building material that has proven itself from the positive side, is suitable for insulation both outside the brickwork and inside the brick structure, has good technical characteristics, is relatively inexpensive, gives a noticeable reduction in heat losses after the end of the insulation work.

The process of installing mineral wool is a bit like the process of laying foam.

It is also possible to prepare a heatable area for work in another way. In this method it is necessary to erect a crate. The cladding is made of vertically spaced racks, the spacing between which directly depends on the width of the material purchased for the product of thermal insulation. Warming brickwork in this way, you need to remember that the insulation sheets should be located close to each other.

Step by step this process looks like this:

- the equipment of a crate;

- a layer of waterproofing;

- filling with mineral wool;

- laying of the layer for insulation from steam (all layers are fixed by the rails of the crate);

- layer of finishing material (as already described above - any desired and affordable option).

Let's sum up the results

- The thermal insulation of any brick structure can be performed both outside the building and inside.

- Thermal insulation is made inside only when it is impossible to make it outside.

- The technology of laying insulation is directly dependent on the material purchased.

- Warming up with foam plastic, it is important not to forget to do the preparatory work on the surface, in order to avoid the holding of cold between the walls and the building material.

- The surface can be brought to an even level with plaster solutions.