It is known that in wooden houses, boxes for windows and doors perform a maximum of useful functions. We will not hide, the casing increases the cost of construction. However, the deflections of logs and beams, the destruction of window frames and crevices will be ruled out if you correctly calculate and select the material for the design.

Content

A window or the creation of casing boxes

For a long time, an integral part of the device for opening windows and doors in a wooden house was a window or a casing that serves to improve thermal insulation and prevent the deformation process when the blocks are shifted during shrinkage.

The technology of the device in the wooden house of the window is specific and involves the absence of a rigid fixation of the door or window to the end parts of the openings.

casing design

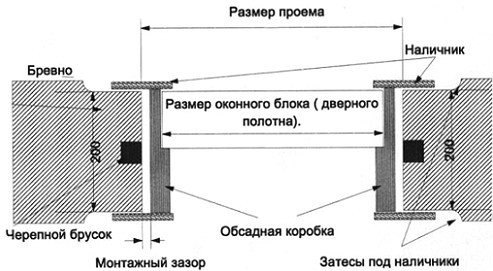

Structurally, a casing for windows in a wooden house and doors is a wooden frame consisting of paired vertical and horizontal racks and crossbeams.

This design is typical for the windows of a log from a beam, a log and a carriage. The connection of the lower crossbars (threshold) to the ends of the log is made with a stud joint. Vertical bar (top) and shrinkage gap compensate shrinkage forces, preventing deformation in the form of twisting or bulging of wall logs and beams.

The width of any casing should correspond to the thickness of the walls and is 210 mm for a monolithic house and glued beam, 250 mm for a solid log. Boxes are made from a beam or a furniture board of δ = 45 mm.

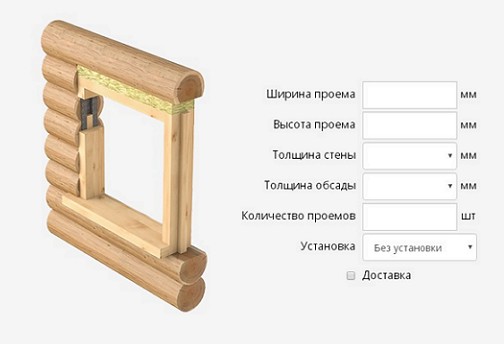

To create a casing, you need to calculate and select the size of windows or doors.

We calculate the size of the windows of the window

Experts recommend choosing windows taking into account the location of the lower edge of the opening in the wooden house along the height of the window sill from the finishing floor (900-1100 mm).

Before the beam ceiling from the top edge of the opening should remain the minimum width of two beams or solid logs.

From the edges of the opening to the corners of the walls of the house, the minimum distance is 200 mm, the recommended distance is 500 mm.

Depending on the size of the windows, the window details are calculated taking into account the joints and indicate the height of the slot opening.

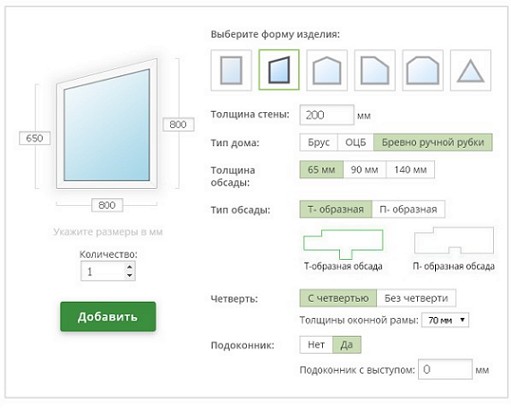

To calculate the window of any configuration and dimensions, it is recommended to use the calculator.

type of casings and possibility of application

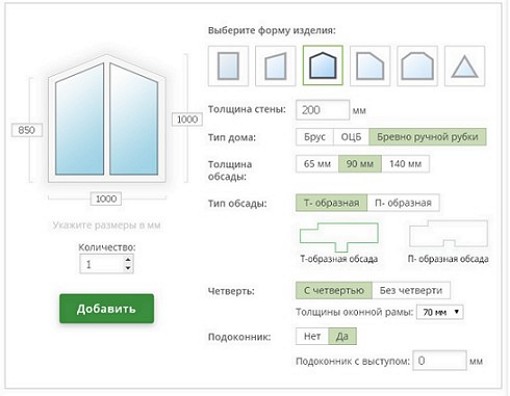

There are several types of wooden house T-shaped and U-shaped configuration:

- in a deck with the use of an end spike

- with the installation of a mortgage bar.

Classical type of the window is considered a clean U-shaped casing.

This configuration of solid wood with fastening "in a deck" is best suited for installation in the openings of a wooden house from a beam, a log and a carriage.

A window "in a deck" or T-shaped with a prepared quarter is used as a finishing version of the casing for the door. The quality of a finishing casing is characterized by chamber drying and a high class of grinding.

The method of installation in the openings of the wooden house of the casing on the embedded beam is considered by experts to be an economical option, allowing to install a window or door directly on the slip bars.

The type of installation of the window on the base bar allows you to install a window:

- in a rectangular window opening up to 3 sq.m.

- in the trapezoidal shape with one or two bevelled edges

- in a standard balcony block.

The possibility of using a casing is expanded by creating original openings configurations.

Casing assembly conditions

Obligatory conditions for assembling the casing for windows and doors are the following:

- for the purpose of sealing between the logs log or beam necessarily place a heater

- it is prohibited to use metal fasteners in the assembly and use of paint and varnish aggressive materials.

How to install plastic windows in a rectangular opening of a wooden house, shown here

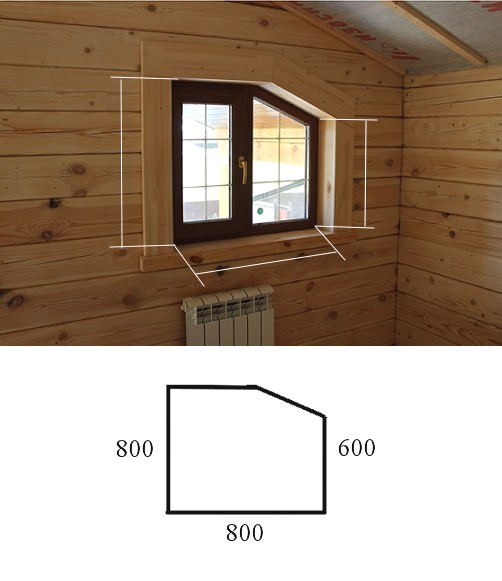

Naturally, a more complicated form of the window will have to be calculated and made up an uncomplicated drawing. Let us suggest that the properties of a rectangular trapezoid are taken as the basis for the drawing to create a trapezoidal casing.

The matter remains for the manufacture of a casing for calculations and a drawing.

Make a trapezoidal casing with your own hands

preliminary calculation of trapezoidal casing details

For the euro-trap in the form of a trapezium, two side boards with dimensions of 800 and 600 mm are required. The length of the lower crossbar is 800 mm, the top consists of two boards - a straight section 400 mm in length and a board of a sloping part 430 mm long, one end of which is connected to a short side.

Prepare the casing boards lateral according to measurements and calculations.

determine the size of the shrinkage gap

It is necessary to take into account the age of the wooden house to determine the size of the shrinkage gap under the window. For a house that is less than 5 years old, the gap size is:

- glued beam - 50 mm

- solid logs - 80 mm

- log house - 120 mm.

The mounting gaps for height, width, left / right and bottom are 15 mm.

Thus, the width of the aperture, taking into account the trapezoidal shape and the clearance gaps, will be:

800 (window) + 30 (gaps) + 60 (window) +30 (gaps) = 920 mm.

The angular joints of the structure are sawed by hand, leaving the minimum gap thickness at the junctions and joints. The surface of the assembled box is polished and, if necessary, stained. If the wooden house is not supposed to produce additional finishing, the walls and apertures with a window are left in the natural form of a living tree.

Sawing an opening and making a casing of a rectangular shape is shown in the video.