When erecting roofs of houses with the use of new heat-insulating materials, an obligatory condition is the installation of a roofing and under-roof space, which is provided by the crate and the control grating. The erection of the crate is considered an indispensable element, without attaching in some cases the significance of the counterbrush.

Content

- 1 Roof lining and control

- 2 Control device

- 2.1 choose the right lumber and fasteners

- 2.1.1 mounting nails

- 2.1.2 nail consumption per connection

- 2.2 basic circuit

- 2.2.1 cornice overhang

- 2.2.2 mounting on the ramp plane

- 2.2.3 stepping crate

- 2.2.4 control of the hip

- 2.2.5 Endowa

- 2.2.6 Gable

- 2.1 choose the right lumber and fasteners

On the shoulders of the rebound is the main burden of the roofing system, which must be evenly distributed, working in cooperation with the crate. Naturally, the properly designed and assembled structure is able to provide the necessary functions for leveling and ventilation of the roof.

Roof lining and control

Significant elements of the roof structure are the crate and the control bar, which should be distinguished by purpose and device.

Recall that the crate is a trellised construction of wood and less often of metal, which is placed on the roof over the rafters system or more specifically over the rafters' feet.

Such a foundation is an enhancement of the spatial structure and serves as the basis for fixing the roofing. Exaggerated crate represents parallel rows of boards (beams), nailed directly to the rafter system.

A control bar of wooden beams is placed on the roofing hydrobarrier material to create the necessary ventilation duct between the crate and the flooring waterproofing layer.

Therefore, it is possible to clarify and resolve the trivial question: "What is the difference between the controllable and crate" and determine the functional purpose of the control lattice: ventilation and alignment.

Control device

choose the right lumber and fasteners

For the device of the control device, it is envisaged to use a coniferous timber bar with a humidity of no more than 25%, without pronounced wood defects, treated with an antiseptic, section 50x50 mm and a beam length of 1370 mm.

When forming the roof vent, the beams and bars simultaneously fix the waterproofing material, the diffusion membrane web, forming a gap and removing the condensate moisture of the under-roof space. Experts recommend that for multi-pitched roofs and ramps, whose length exceeds 6 m, choose beams 50 mm high.

mounting nails

The bars of the counter block are clogged with galvanized nails of 120 and 150 mm. In practice, it is possible and recommended using screwed and screw nails. Undoubtedly, the size of the nails for fixing the crate and the grating depends on the thickness of the nails.

For nail thickness up to 30 mm, nails of 70 mm are used, for curtains up to 50 mm - nails 100 mm, for thicknesses of more than 60 mm nails 120 mm.

nail consumption per connection

For wooden beams with a section of 50x50 mm, the consumption of nails for connection is one.

To connect the crate with a width of 60-120 mm to the rafter's leg, 2 nails are sufficient, along the battens the number of nails alternate (2-1-2-1-2).

basic circuit

The basic scheme of the device of the control lattice assumes the creation of:

• The main structure of the roof slopes

• control the valley of the valley, the hip (roof ribs) and the pediment.

The process of installation is basically the most simple and consists in the layout of film roll material, on the surface of which will be stuffed pre-prepared bars.

To insulate the roof of the control box, there will be a need to calculate the stepped crate and its correction.

Work should be carefully, not trying to damage the waterproofing material and evenly pull it after each stuffed row.

The device of the control device begins with the eaves.

cornice overhang

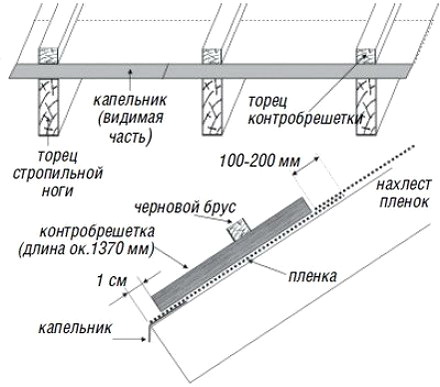

The control bar (counter-bar) cornices are stuffed over the installed waterproofing, displacing the lower edge of the beam by 10 mm towards the ramp with respect to the drip.

mounting on the ramp plane

Initially place a drip and fasten on the rafter, then roll out a row of waterproofing material. On top of the installed waterproofing, mount and fasten a long block with a landmark to the overlap mark.

After the installation of the counter-beam, a step-shaped crate is erected on the cornice overhang, which will facilitate the subsequent assembly of the control unit.

Over the first row of waterproofing and the beginning of the lathing, which will ensure the convenience of subsequent installation, begin the second row.

stepping crate

The need for a stepped lath is dictated by the fixation of the roofing material on its surface. Naturally, it is necessary to treat the step of the battens with knowledge of the matter. Let's tell, the step of the crate can be 30-39 cm and depends on the width of the exposed roofing material.

The release of the roofing material is 2-4 cm. The stepping crate along the entire length should be the same and it is placed strictly parallel. In exceptional cases, it is recommended to make a correction for the stepped roofing.

The bars of the rebound are used to create a ridge connection, facilitating the formation of the ridge and widening the boundaries of knowledge about what a grating strap on the roof is for. The upper bars of the beam are sawed according to the configuration of the installation angle.

More difficult is the creation of a restraint on hips and in the valley.

control of the hip

To create a rebound on the roof edges, choose the maximum length bars that are fixed on both sides of the ribs up to a distance of 40 mm. the reference point is the edge of the rafter's leg, which is the carrier of the hip. It is important to ensure the docking on the rafter's feet. In addition, it is necessary to provide a clearance of 15 cm between the ends of the ribs and the counter-beam.

Endowa

The roof valley is considered complex, so certain rules are imposed on it. Let's say that the distance between the bars in the valley should be 200 mm, the counter-beams should be docked on the rafters. It does not hurt to remember that in places where nails are fastened to the rafter, waterproofing with a sealant is recommended.

Gable

The organization of the gable frame is carried out after the end of the general installation of the crate and the beams are packed along the length of the gable overhang from the inner crate side. The joints of the beams are produced in the center of the battens, and for the filing of the overhang of the gable, 2 extremely disposed beams are additionally fastened. Fastening is carried out in the outer timber.

More information about the device in the video monitor.