How much labor and technical solutions, tested by time and exploitation, were invested in bath ovens, so that the creations delighted the eyes and experienced a change of historical epochs. The existing set of modifications of furnace equipment for baths favorably applies to the demanded gas equipment. The design of gas burners in the form of ready-to-use devices, literally allow the installation or conversion, if desired, of a wood-burning stove, without problems.

Content

Bath ovens and aggregates, how to choose

The choice of a sauna furnace begins long before its construction and arrangement, carefully comparing the characteristics of a wood and gas furnace. We will not conceal, any furnace has positive and negative qualities - a rapid heating of the steam room and the removal of combustion products.

Traditionally, wood-burning stoves are considered the best when creating the atmosphere of a Russian bath with the fervent heat of a heated stove and the aroma of a steamed broom. The problems with the preparation and harvesting of firewood, the terrible stories about the sauna burned last year in the village, go to the background.

For practical and lazy lovers of steam, the greatest interest is in gas sauna furnaces with the simplicity of the process of kindling and the automatically maintained temperature of the steam room. Naturally, the choice will be yours, therefore, for an informed decision, you need to have strong arguments in the form of comparative characteristics of the sauna stoves.

compare the characteristics of wood and gas furnaces

Any sauna stove from the manufacturer must provide the declared thermal power in a dynamic range, be convenient and fireproof. Gas sauna ovens provide the best and maintain a dynamic range of power with the use of non-volatile automation.

Comparative analysis begins with the main advantage of a gas oven for a bath - the time of heating the stove.

Warm-up time for the heater

The warming-up time for the stove's sauna heater is on average 1-2 hours (prepared dry firewood in the required quantity). Heating with a steam oven is 40 minutes. Due to what the heating of the sauna heater and the warming up of air is accelerated without the presence of the bathhouse attendant? The speed and reliability of the heating process is ensured by gas burners for sauna furnaces with automatic SABK-T.

features of burners of gas furnaces

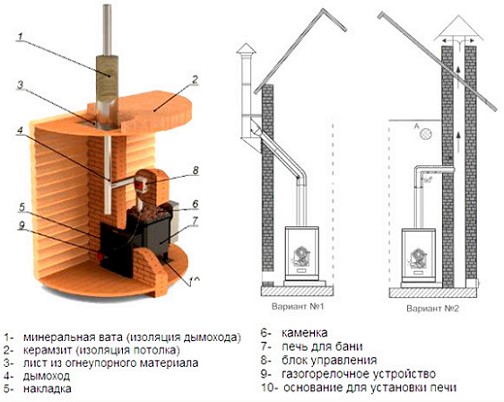

Mounting block

Gas burners in the form of burners with thermal power from 13 to 40 kW and a nominal gas pressure of 1.5 kPa are mounted in the fuel channel of the furnace. The installation unit consisting of a panel with a viewing window, a traction sensor and short flare burners of full mixing of a nozzle nozzle of 15-20 mm and a uniform gas jet flowing at a speed of up to 300 m / s, provide k min of excess air when a high temperature is reached.

For example, a gas bath oven with a steamy volume of min 6 m3 and max 18 m3, with a remote heat exchange system of a closed furnace distributing the evenly heat load and the central location of the chimney, is equipped with a burner with non-volatile automatics SABK-3TB4 (PB-19-23 kW). The automatic mode of the set temperature provides in the steam room from 60 to 120 ° C even in your absence.

Control block

The convenience of controlling the gas burner is confirmed by practice. The control unit with the start button and the temperature sensor is placed in the waiting room, placing the device on the wall of the room at a certain distance from the gas burner.

Detailed information on furnace gas automatics is presented in the video.

Helpful Tips

Many people know about the benefits of automation for the operation of furnaces, boilers and other units operating on natural gas. Recall that the automation of gas furnace burners is set to work with a nominal gas pressure in the network of 1.3-1.8 kPa, with an inertial period of switching on the automation for no more than 1 minute, fuel combustion heat is up to 35570 ± 1780 kJ / m3.

For reference: the heat of combustion of firewood of 20% humidity is 1500-2200 kWh / m3, and manual ignition of firewood can last up to half an hour. Moreover, producers of solid fuel stoves are slightly cunning, promising to quickly reach the specified capacity of 15-20 kW from a wood-fired oven.

The gas-fired equipment provides not only a given temperature regime in the steam room, but also discharges the combustion products through the chimney for the gas bath furnace.

In addition, any furnace should have a light steam and heat accumulator, creating a thermal regime with maximum comfort.

Reviews

why a gas furnace was installed

Sergey Vladimirovich, the owner of a private house and a gas sauna furnace ermak

To be frank, the gas bath oven Ermak is the most successful acquisition. Bribed the functionality of the unit with the ability to change and select fuel. At first I thought that it would be difficult to switch from low-pressure natural gas to firewood or vice versa. I will mention the advantages of a gas furnace:

• small overall dimensions 700х500х755 mm

• burners with combustion control

• Possibility of precise temperature setting using automatic SABK-3TB with a power of 12 kW.

In addition, it was intended to install a hot water tank in a nearby washing room, which was safely done by hand.

Am I going to switch to wood heating in the future? Probably not. But I certainly will, so I will conclude a long-term contract for the maintenance of the unit.

About the models of the gas sauna furnace, reviews and useful tips are presented here.