In the process of living a suburban area and improving the management of economic activities on it, owners have a desire to build a greenhouse. This trend is connected with the desire to receive environmentally friendly products for the family, not only in summer, from beds in open ground, but throughout the year. Naturally, there are many questions about the arrangement of the greenhouse, in particular - the materials for its manufacture.

Content

- 1 Which polycarbonate is better to choose for a greenhouse

- 2 Designing - how to draw a drawing of a greenhouse made of polycarbonate

- 3 How to make a greenhouse made of polycarbonate - the order of work

- 4 Winter greenhouses made of polycarbonate

- 5 Recommendations for the construction of a combined winter greenhouse

Which polycarbonate is better to choose for a greenhouse

If you approach the choice of material for the greenhouse in terms of practicality and economic benefits, the decision to use polycarbonate will be the most reasonable:

- polyethylene film burns in the sunlight throughout the year, its annual replacement is an additional expense of time and money,

- glass - does not react to the influence of ultraviolet, but it is brittle and too cold for structures that require maintaining a stable temperature inside.

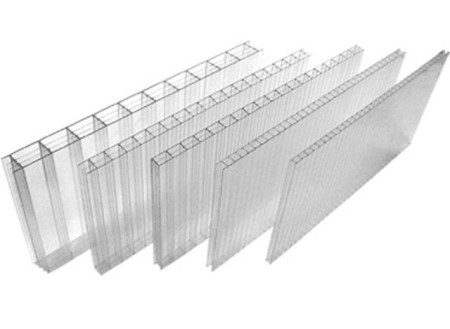

Let's clarify that polycarbonate is of two kinds. Monolithic sheets have a higher cost, the coefficient of their heat savings is inferior to that of a cellular material. At a lower cost and a suitable indicator for the greenhouse thermal conductivity, honeycomb:

- has a large sheet size, to avoid unnecessary seams on the surface of the greenhouse,

- it has plasticity, which allows to equip arches of any radius,

- has a relatively small specific weight,

- it makes it possible to avoid obtaining a large number of scraps during installation,

- differs strength, resistance to loads created by wind or snow,

- most importantly - it keeps the heat inside the building well.

Another important fact in favor of a greenhouse made of polycarbonate is the ability of a material to scatter light, this will protect young plants from getting sunburn.

To build greenhouses from polycarbonate with their own hands, you can use sheets of material 4-10 mm thick. Thinner than 4 mm, the material does not exist, the thicker - will significantly increase the cost of the structure. In addition, when using a material thicker than 10 mm, the construction of a greenhouse or a greenhouse with an arch radius of less than a meter and a half is not possible.

The optimum thickness and cost will be polycarbonate 6 mm thick.

When constructing a hothouse collapsible arched type, you can use a material 4 mm thick. But it should be borne in mind that its surface can be seriously damaged by a large hail, a hurricane wind or heavy accumulation of snow in winter. 6 mm material suits well blows of medium-sized hailstones, even in the event that dents remain, the integrity of the material will be preserved.

When manufacturing the material on one of its sides is applied a film-protection from ultraviolet radiation. During installation, the film-coated side must be on the outside.

Do not buy polycarbonate with suspiciously low prices - in the course of its production cheap "additives" could be used, the life of such material will be very short.

Designing - how to draw a drawing of a greenhouse made of polycarbonate

After choosing the material, you should think about the location of the greenhouse and its structural features. That the greenhouse has served many years it will be required:

- comply with building codes,

- on the basis of the drawn up drawing to execute calculation of loads on a skeleton,

- depending on the results, choose the correct shape of the frame and the material for its manufacture.

When drawing up a blueprint or scheme of a greenhouse, it should be borne in mind that the main load on its construction will be a snow cover, which will appear in winter during heavy snowfalls. Therefore, the shape of the upper part of the structure should prevent the possibility of accumulation of a large snow mass. But, even in case of its adherence, the roof of the structure must withstand the increased loads.

If there is no possibility to build a powerful frame, then during the whole winter it will be necessary to systematically clean the roof of snow accumulating on it. This is quite troublesome, but less expensive in terms of money.

Since the operation of the greenhouse is associated with the formation of a special microclimate within it, the carcass material should be selected to be resistant to high temperatures and moisture. Lumber, pipes or metal profiles used in construction must be treated with appropriate antiseptics or anticorrosive agents, then opened with special paints - this will help prolong the durability of the structure.

When designing the project, a door and ventilation pans should be provided for ventilation.

In order to determine the size of the structure, it will be necessary to decide which areas will be used for the cultivation of vegetable crops. A greenhouse made of polycarbonate, the dimensions of which exceed 50 square meters. m can be used for growing vegetables for sale. Revenues received with its rational use will quickly pay off the funds invested in construction. For conducting commercial economic activities, the recommended size of the greenhouse is 100 sq.m.

The minimum width of a greenhouse of any area is two and a half meters: a passage of 0.9 m and beds on both sides of it with a width of 0.8 m.

How to make a greenhouse made of polycarbonate - the order of work

foundation

There are several options for the foundation:

- the most simple, but unreliable, is the immersion of vertical beams of the greenhouse into the ground or fixing them to a steel corner immersed in the ground,

- the use of a wooden beam 100x100 mm, laid along the perimeter of the structure - even when impregnated with resin or antiseptic, its service life will not be long,

- cinder block, foam block, bricks - relatively cheap and reliable materials for creating a foundation,

- the most expensive, however, the most durable and reliable - built of monolithic reinforced concrete around the perimeter; when you bookmark it you will need:

- digging a trench,

- installation of reinforcing frame,

- concreting.

For the construction of a greenhouse is better to choose a site with an even surface of the ground. The illumination of the site should be good, it is desirable that the length of the structure is oriented in the direction from east to west.

carcass construction

The best form for the design is an arched frame - the most economical in terms of consuming the material; in winter, snow accumulates on such a greenhouse; The predicted load on the frame will be minimal.

There is an opportunity to reduce the material consumption of construction and the loads exerted on the foundation. But the standard dimensions of the material make it possible to construct a greenhouse with a height of not more than 1.9 m and a width of 3.8 m. If a large height is required, it will be necessary to build a socle.

The construction in the form of a house with a roof allows to build a greenhouse of any size, but at the same time the consumption of materials on the frame will increase - it will be necessary to strengthen the stiffeners.

what material to choose for the frame

Although the wooden beam is of low cost and very easy to install, but given its fragility in the construction of greenhouses made of polycarbonate is used extremely rarely. A more acceptable option is to use a steel pipe with a square section of 20x20 mm with a wall thickness of 2 mm. The frame is assembled by welding. But to make the pipe the right shape you will need to use a pipe bending machine, in principle, to facilitate the task, you can purchase ready-made, already curved pipes.

Ideal - an omega-shaped profile that allows you to create a reliable and lightweight design. Of course, you have to work hard at drilling holes in the metal for bolts.

assembly

The assembly process takes place very quickly, its main features are the use of self-tapping screws with a press cup or screws with a thermowell as fastening materials.

Cutting sheets are made with a hacksaw for metal or electric jigsaw.

The overlap should overlap about 7 cm of the next sheet, the seams are sealed with a metal self-adhesive tape from the outside and a polymer tape from the inside. You can buy fasteners and other materials necessary for work in companies that deal with the sale of polycarbonate.

More details about the assembly process can be found by watching the video.

Winter greenhouses made of polycarbonate

If the greenhouses are to be used throughout the year, it will require the construction of a specially designed structure. Its complexity to some extent will depend on how much the plants planned for planting are heat-demanding.

Not bad, if it is possible to build a house greenhouse - it will be warmer and more protected.

In order to save money for heating, you can choose the option of building a greenhouse deepened in the ground or located on top of a barn or a garage.

The architectural solution of the roof can be different, but if you plan to do the work yourself, it should be noted that the easiest to install - arched structures and houses with a gable roof.

Since the main purpose of the greenhouse - the preservation of heat, the choice of material with a sufficiently low coefficient of thermal conductivity - a very important moment. Suitable is a cellular polycarbonate with a sheet thickness of 10 mm. It is not afraid of low temperatures, has high strength and low weight. Installation of a winter greenhouse will require a particularly careful joining of sheets, the formation of cracks between the sheets is unacceptable.

The optimal option will be the construction of a strip foundation with a concrete base. A place for construction should be chosen as much as possible illuminated, sheltered from the wind.

When designing winter greenhouses from polycarbonate, it will be necessary to provide for the possibility of installing a heating system. If it is planned to use stove heating, then it is best to provide for the presence of a tambour - it will be possible to build a stove with a chimney or install a "burgulet", when installing a hot water heater, it installs a boiler for heating water. To reduce the cost of heating, you can also use an auxiliary subsoil heating method - it consists in laying a thick layer of biofuel under the beds, i.e. manure.

Recommendations for the construction of a combined winter greenhouse

Experienced builders recommend the construction of combined greenhouses for winter use. At the same time, a monolithic or brick base with a height of up to 120 cm is expelled, a metal frame is assembled on it and covered with cellular polycarbonate. The thickness of polycarbonate should be 8-10 mm. It is recommended to make the roof a gable, at one-pitch - the slope should be at least 20-25 degrees.

Wiring the electrical cable to the greenhouse can be done in poles or underground. Preparatory work: installation of poles or digging trenches, you can do yourself, better connect the connection to a professional electrician - in the premises of the greenhouse very high humidity, poor performance of electrical work is associated with the risk of electric shock.

Winter greenhouses must be equipped with a system additional lighting - prolongation of the daylight will favorably affect the yield of plants and accelerate the period of fruit ripening.

Care of the greenhouse of polycarbonate will consist in the periodic washing of its walls, in particular - before planting new plants. It is not advisable to use hard brushes or detergents. In winter it will be necessary to remove the snow that has lingered on the roof, you can do it with a soft broom.

Life time winter greenhouse of polycarbonate, with the correct assembly will be at least 12-15 years.