Brick is the most popular and reliable material not only for construction, but also for facing buildings. Due to the variety of colors and sizes, you can create a unique design. And most importantly, this decoration will serve a very long time, unlike other facing materials. In addition, the cladding will serve as additional warmth to the house. About what kinds of facing bricks are, what sizes exist, let's talk more about this article.

Content

Facing the house with a brick

Any owner of a new or old house wants to give his home a presentable look. It is best for him to help with facing brick.

It is perfect for finishing both stone and wooden houses. Before you tile the house with a brick, you need to make sure that the foundation and the roof are sound. If the foundation is not reliable, it must be strengthened by pouring an additional layer. After all, the building weight of about 100 square meters can increase by 40 tons due to the cladding. As for the roof, a visor with a length of 25 cm should be provided. It will protect the wall from moisture and destruction. Therefore, if necessary, you need to extend the overhang of the cornice. The durability of the facing of the building depends on this.

For example, for facing the house you can pick up a yellow and brown facing brick. The main mass of the wall is done in a light tone, and the corners of the building, the perimeters of the windows and doors are highlighted in brown. It looks so very warm and cozy.

You can choose a red material and overlay the whole house with it. The building will be in the classic English style. This is a fairly simple and stylish solution.

Types of facing bricks

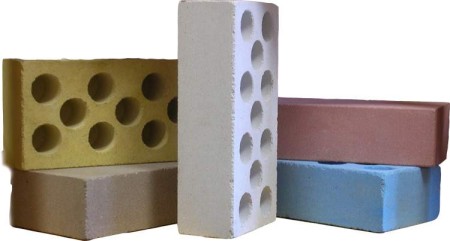

Depending on the materials of manufacture, the brick can be divided into the following types:

- silicate;

- hyperpressed;

- clinker;

- ceramic.

Lime brick this is the most budgetary version of the cladding, but it is considerably inferior in appearance to other varieties. To its pluses, one can refer to ease with respect to other analogues.

Hyperpressed. It is made of limestone, cement additives and dyes by high pressure. Firing to these products does not apply. This is a very strong material that is not afraid of strong temperature changes. Due to the manufacturing process, the brick chip is an inverse texture and resembles a natural stone. This is often used by designers for decorating houses.

Clinker brick This is a kind of ceramic, which we will discuss below in more detail. This material is manufactured using a special grade of clay and at higher temperatures. Thanks to this technology, the product is produced with high density, which contributes to low water absorption. And this means that it will last for such a long time without cracks and chips. This brick can produce different sizes, shapes and colors.

Brick, cladding

This brick is the most common kind. It is made of clay with the use of various dyes. The positive qualities of ceramic bricks include:

- low thermal conductivity;

- frost resistance;

- high-temperature strength.

Ceramic bricks have exact proportions and a smooth surface. It can be used in any conditions. In addition to the standard shape, the product is manufactured in several versions:

- glazed - it has a transparent, shiny coating that not only improves the appearance, but also increases durability;

- engobed - covered with a matte, opaque glaze (the so-called engobe), this allows you to expand the palette of colors and serves as additional protection;

- textured - the surface of the brick imitates various textures: tree bark, leather, etc .;

- shaped - the surface is artificially aged and has cracks and chips on the surface of the brick.

This material has an affordable price and looks great on the facade of buildings.

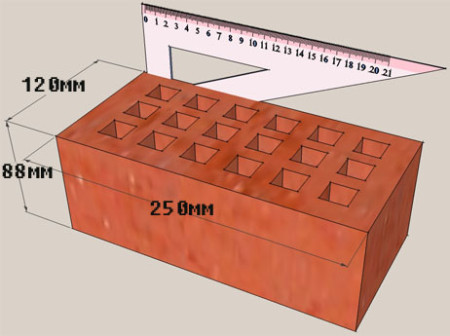

Dimensions of cladding brick

Brick, as well as other building materials must have the dimensions defined by standards. But it was not always so. Until 1927, each manufacturer produced a brick of its own size, and there were no specific dimensions of this material, resulting in many inconveniences. But in 1927 standard brick sizes were set. The most optimal dimensions of the brick were established in practice:

- length 250 mm;

- width 120 mm;

- thickness - 65 mm.

These dimensions correspond to a single brick. Construction technology does not stand still, and soon there was a need for the production of bricks of other sizes. So the following dimensions appeared:

- double (d 250 * w 120 * in 140 mm);

- modular (d 280 * w 130 * in 80 mm);

- Euro brick (d 250 * w 85 * in 65 mm).

There is one more variety, the so-called bastard brick. Let's talk more about it.

brick one-and-a-half facing

Of course, during construction work it is important to meet the deadlines. In order to save time on the masonry, a half brick was invented with dimensions:

- length 250 mm;

- width 120 mm;

- thickness 88 mm.

It is larger than the standard one, which means it will be faster to make a masonry from it. So, for example, to calculate 1 cu. m of a single brick will require 512 pieces, while a one-and-a-half brick is only 378. And this is 26% less. From this it is necessary to draw conclusions:

- time for masonry is reduced;

- less material;

- funds are also spent less.

If, by its physical characteristics and appearance, the brick is not inferior to its counterparts, while saving money and time, one can give preference in the lining of the house to him.

Brick, cladding, red

Basically, this color has a ceramic and clinker brick. They are made of clay in admixtures of metals, which give the product different shades of red. For example, iron in the composition gives a rich red color. Also, the color of the finished product depends on the roasting, the longer the product is burned, the darker the tone is obtained. Such a brick can be clad as all the walls, and lay out of it individual elements.

Brick, yellow, cladding

Yellow brick is produced from a mixture of cement and limestone - shell rock with the addition of natural dyes. The most commonly used technology of pressing, as a result of a durable and environmentally friendly material. Yellow brick is offered in several shades:

- pale yellow;

- straw;

- amber;

- golden.

This brick has good technical characteristics and is suitable for finishing the facades of buildings, even in regions with severe climate.

White facing brick

White brick is one of the varieties of silica brick. It is environmentally friendly and much cheaper than its ceramic counterparts. The only drawbacks are heavy weight and intolerance to excess moisture. From an aesthetic point of view, this is an excellent option for facing the house. Masonry from it looks very neat and stylish. It can be supplemented with a different color material, creating interesting patterns. Due to the production capabilities of the brick, it is possible to give a creamy shade.

How much is facing brick

Before proceeding to the lining of the house, it is necessary to calculate the necessary amount of material and the approximate cost. So, the price of ceramic bricks varies from 9 to 44 rubles apiece. Material with a textured surface or icing will cost more. The price of silica brick varies from 8.5 to 22 rubles per piece. Hyperpressed brick, depending on the color and texture costs from 8 to 38 rubles apiece. The most accessible of all types of materials is silicate brick. It has good physical characteristics and attractive appearance. With the acquisition of bricks, there should be no difficulties. Now many construction shops sell a wide range of facing bricks. If desired, you can make an order from the manufacturer with delivery to the destination. The only thing is to correctly calculate the amount of material and best of all with a margin, so you do not have to buy a brick.

This article describes the types and sizes of facing bricks. Also give advice on the facing of buildings. Using the material of the article, you easily pick up the kind of facing brick you need and calculate the approximate cost of the material. Good luck in the arrangement of the house.