Bath in a private area is a great place where you can meet friends, relax and relieve stress after hard work, improve your health. Not everyone has the opportunity to order a bathhouse on a turnkey basis and then have to erect it with their own hands. We hope that this article will be useful in the preparation and self-construction of a sauna made of bricks.

Building a bath of bricks, step by step instruction

choice of location

Before the start of construction, you must carefully choose the place for the bath. Well, if the building will be on a small hill to simplify the drainage of water. The entrance to the bathhouse is usually equipped in the direction of the main building located on the site. Distances to the boundaries of the site and various buildings should be within the limits of the existing sanitary standards. The bath can be attached to the existing building, thereby simplifying the connection of communications and saving construction materials. It will not be superfluous to discuss the planned construction with the owners of neighboring sites, so that there are no disputable issues after the completion of work.

soil investigation

When designing a building, it is necessary to clearly know the nature of the soil, which will be the natural basis for the foundation of the structure. This base must have good load-carrying capacity and allowable in the magnitude and uniformity of the draft. If it is not possible to conduct a detailed study, then it is worthwhile to take advantage of the experience of erecting similar structures in neighboring areas.

Ground on the strength, water permeability, structure, texture and other parameters is divided into dozens of all kinds. For non-specialists, the ground conditionally can be divided into several types.

- Rocky ground is a hard rock, it is slightly affected by frost and moisture, has high load-bearing properties, does not sag, does not wash out, does not puff up and is the most resistant to foundations. On a rocky soil it is possible to erect a building without penetration.

- Coarse clastic soil includes rock fragments of rock size not less than 2 mm, the distance between which can be filled with sand, clay. Such a soil weakly succumbs to compression, but is capable of puchinitsya, if it has in its composition finely dispersed sand or clay. On this soil, a foundation can be used with a depth of not more than 0.5 m.

- The sandy soil consists mainly of sand and is slightly susceptible to freezing. For sandy soil, the strip foundation, buried below the freezing level of the ground, is most often used. Through the sand water flows well, so the foundation is practically not prone to blockage. The more constituents of the particle, the worse the ground retains water and less exposed to whipping. The foundation in such a soil must be buried within 1 m, the sludge of the building takes a little time.

- Clayey soil is very plastic, well retains moisture, can be washed out in case of heavy precipitation, shrink when dry and freeze to a depth of more than 150 cm. Dry clay is a strong material, but in the liquefied state, the bearing capacity is extremely low. In the case of freezing, the soil undergoes significant puffing and increases in volume up to 15%. Clay soil is considered unfavorable and for the erection of a heavy building it is better to use a monolithic foundation. The process of settling a building takes a long time.

- Peatlands are soils containing organic impurities. Peat can be referred to peat bogs, they have a high water content and are characterized by considerable uneven compressibility. This soil is not suitable for a natural foundation, so when laying the foundation, it changes to a denser one.

- Quicksands are fine-grained soils and become very mobile with a large amount of water. Quicksands are of little use for construction.

- Bulk ground is most often of artificial origin and is formed by filling up ravines, ponds, etc. It is not used in construction due to its heterogeneous structure. It is possible to build small buildings, provided that the soil has been caked for a long time, but not less than three years.

A pudding is the expansion of frozen moisture in the soil and the creation of a buoyancy force that is applied to the foundation. Under certain conditions, the pressure on the opposite sides of the foundation may be different, which causes damage to the foundation and the building installed on it. To avoid this, it is necessary to deepen the foundation below the freezing level of the soil.

The upper fertile soil layer is considered unsuitable for construction and must be removed when preparing the site for the foundation.

To determine the nature of the soil, it is necessary to excavate a pit not less than a meter deep, take a sample of soil from the bottom, moisten and mash so that it has the consistency of a thick dough. If a specimen rolled up to a cylinder about a centimeter thick can be rolled into a ring, then the clayey soil on the site, if folded, but the clay is cracked; clayey soil with a high content of sand. If the ring breaks up into parts, the soil is sandy loam - a sandy soil with a significant amount of clay. If the soil can not be rolled at all, the soil on the site is sandy.

project development

Traditional Russian bath is built of wood, the main advantage of which is the simplicity of construction and relative cheapness. Wooden bricks are built not less often than wooden ones on personal plots, which have a number of positive qualities. They are ecological, durable, fireproof and durable, it is possible to erect buildings of various shapes from brick. At the same time, compared to wood, bricks have a b aboutthermal conductivity and vapor permeability, which will require careful heat and vapor insulation. If there is a desire to build a bath above a single floor, in which there will be a pool, a lot of rooms for various purposes, then the choice is for a bath of bricks.

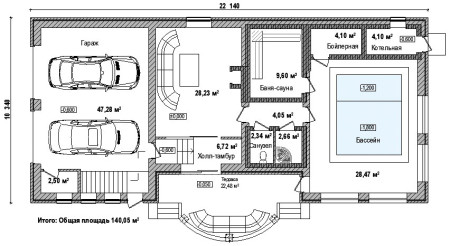

The projects of baths made of bricks are so diverse that it is impossible to offer any one definite which would suit all. Are constructed as small and inexpensive baths in which there are only the most necessary premises: a steam room, a rest room and a shower room, and huge expensive complexes with swimming pools, bathrooms, guest rooms, technical rooms, a gym and even a garage. Everything depends on the imagination, the size of the plot and the financial capabilities of the owner.

When calculating the project, you should know that the hot air always tends to rise, so it is undesirable to do more than 210 cm in the pair height of the ceiling, as it will be difficult to achieve a quality steam. The area of the waiting room should be calculated on the basis that one person should have more than 1.3 m 2 free space. If a stove is installed in the steam room, it is advisable to increase the dimensions of the room by the area of the furnace. A shower in a bath is an extremely necessary room. Its calculation should be made based on the norm of 1.2 m 2 per person. If possible, it is worth installing a shower.

For a comfortable stay in a steam room for one person should be at least 1 m 2, and the distance between the furnace and the shelves is at least 1.25 m. When designing a building, it must be remembered that in a steam room it is not recommended to install a window, so it increases heat loss. Heating of air is carried out with the help of a stove-heater. Since for the installation of a heavy stone furnace or a metal furnace lined with bricks, a foundation is required, the choice is made at the design stage. The most expensive and complex will be the installation of a stone kiln, but if a large chic dacha is being built, then this will be a good solution.

Metal furnaces are affordable, small in size and convenient to maintain. A large number of industrial furnaces are on sale. It looks very good with a furnace with a remote furnace and a door with glass. The oven itself is installed in the steam room, and the furnace goes into the waiting room or rest room, where you can see a live fire.

foundation erection

The foundation for a brick bath is the underground part of the building, which transfers the load to the ground. The foundation is a very important element of the building structure and an error in its choice and construction can lead to the fact that, due to uneven shrinkage, walls will crack.

To choose the type of foundation under a brick bath it is important to know the shape of the designed structure, the relief of the site, the nature of the soil, the depth of its freezing, the passage of groundwater. The stronger the foundation of the foundation, the longer the building will last, however, the greater the construction costs.

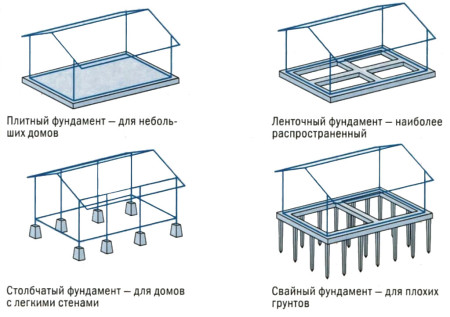

There are different foundations, but usually for the construction of a brick bath is used as far as basic types.

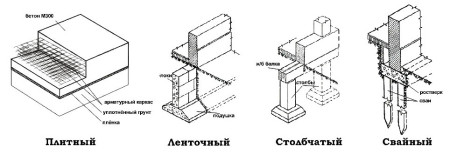

- Plate (monolithic) foundation is a recessed reinforced concrete slab laid on the ground beneath the entire area of the erected structure. It is characterized by increased strength, lower specific pressure on the base and a more even distribution of the load, and therefore can be used on weak soils. The building is less subject to deformation. Plate foundation is much more expensive than other types of foundations, as the consumption of materials increases and labor costs are increased.

- Tape foundation has the form of a tape deep in the ground, which takes over the weight of the entire structure. In order for the load to be distributed to b aboutthe larger the area, the structural elements from below have an extension. Tape foundation is characterized by increased strength and by the type of works performed it is divided into two types: monolithic, poured directly on the site, and prefabricated, assembled from finished reinforced concrete structures. Monolithic foundation from the team differs in that it can be given a complex shape. Most often, the strip foundation is made of reinforced concrete, which allows you to install heavy buildings on it with or without basements.

- The column foundation is a frame of recessed pillars placed at the corners of the structure and in places of increased load. For a more even distribution of load, the pillars from above are combined with reinforced concrete foundation beams. Columnal foundations can be monolithic or prefabricated. Like the ribbon foundation, the pillars that are installed have an extension in the lower part. Various materials can be used to make the pillars: wood (oak, larch, cedar - for small wooden buildings), reinforced concrete and clay brick (for 1-2-storey brick buildings), stone (for heavy brick buildings). The ground, on which the foundation is erected, should not be installed on abrasive soils. The cost of the columnar foundation is much lower than the plate and tape. Disadvantages - low strength characteristics and complexity in equipping the basement and the basement.

- The pile foundation is used on weak soils and consists of buried piles, which are connected in the upper part by a concrete or reinforced concrete grill. For weak soils, only the upper layer of the earth is unstable, so the piles fall below its level and are supported by a stronger layer. Piles are of different design and can therefore be mounted vertically or angled in various ways: they are clogged, screwed, inserted or poured into prepared wells. The pile foundation is used for large buildings, but it can also be used for small buildings, if, due to weak soil, it is not possible to equip other types of foundations. Despite the reduction in the volume of excavation work and the reduction of the material consumption, the pile foundation is quite expensive due to the use of special machinery for the transport and installation of piles.

A bath made of bricks, especially with large dimensions, is a heavy structure that must be supported by a solid foundation. In private construction, a strip foundation is most often used, capable of withstanding the heavy construction of any shape and which can be made relatively easily with one's own hands.

The work begins with the removal of the upper fertile layer and leveling the site at the hydro level. The thickness of the foundation should exceed the width of the walls by 10-15 cm on each side. With the help of stakes and stretched rope, the inner contour of the foundation is first set, then the outer one. After the external walls, the internal partitions and the basement of the furnace are marked out in case a heavy furnace is installed.

A right angle can be set using an "Egyptian" triangle with a 3: 4: 5 aspect ratio, one of whose corners will have exactly 90º. To check the correctness of the markup, it is necessary to check the equality of the diagonals of all the rectangles.

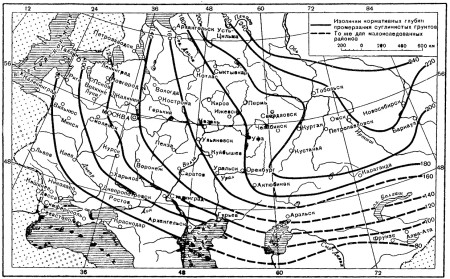

To install the trench formwork for the foundation, dig into 0.2 m wider than the marking line. The depth should be 0.2 m above the freezing level of the soil. The approximate amount of freezing for different regions can be determined from the map.

At the bottom of the trench, a layer of 0.1-0.25 m of sand and crushed stone is filled, which will be a foundation cushion, then formwork boards assembled from edging boards, plywood or other materials are installed. The most economical material for formwork is wood, but even a foam polystyrene formwork can be installed that will perform the functions of thermal insulation. The formwork is exposed strictly vertically, the level to which it is necessary to fill the solution is marked with a horizontal stretched twine. It is desirable to insulate the solution cushion with some waterproof material, for example, polyethylene or roofing material. For easy removal of the formwork after use, it must be lubricated with a special water-based lubricant, and to not rupture with concrete when pouring - strengthen the screed with wire.

In order to give the foundation additional strength in the formwork, a metal reinforcement, connected by wire or fastened with fixatives, is laid. Pour the solution into the formwork it is desirable to do at a time. In individual construction, it is usually impossible to provide all the required amount of a mixture, so either a layered pouring along the entire length is made, or the foundation section is filled to its full height. To compact concrete and eliminate air bubbles, it is recommended to use a deep vibrator, and in its absence it is possible to pierce the mass of the solution with a piece of reinforcement and tap it with a hammer on the formwork.

The solidifying concrete is recommended to be protected from direct sunlight, for uniformity of drying in order to avoid cracking it is necessary to moisten it with water twice a day. And, on the contrary, in rainy weather it is necessary to protect the foundation from water. Shields formwork is better to remove after 10 days after pouring, and full hardening and drying of the concrete occurs approximately for 28 days.

walling

You can start the construction of the walls 10-12 days after the foundation is poured, when it gathers the basic strength. In private construction, in order to save materials, the thickness of the outer wall of small buildings can be reduced to 1.5 bricks; brick is a good conductor of heat, additional insulation of walls is required.

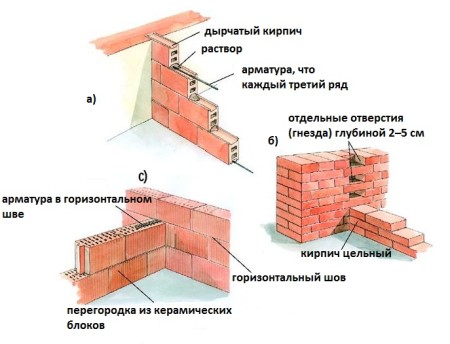

When building walls often used hollow brick, which several times better preserves the heat compared to the usual. However, due to its non-integral construction, it has worse load characteristics and can not always be used for the erection of walls. A hollow brick can not be used to equip the basement and basement and basement premises, only solid bricks are used for these works.

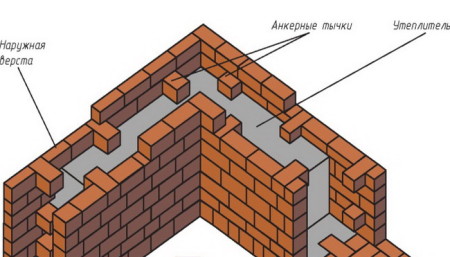

The masonry of the walls is solid and light. Solid is a monolithic structure. Lightweight masonry is often used for low-rise construction. One is two walls of 0.5 bricks at a distance from each other. To ensure the rigidity of the wall are connected by a bridge. The air space between the walls is a heat insulator, in addition, it can be filled with expanded clay, slag, basalt cotton wool, granulated foam glass, foam concrete and other heat-insulating materials. In this case, significantly reduces the consumption of bricks, reducing the weight of the building. Also for lightweight masonry hollow, porous and other types of bricks can be used.

It should be taken into account that the first row is made complete along the entire perimeter of the foundation, and the lightweight masonry begins with the second row. On the Internet you can easily find tables and calculators for calculating the needs of materials for different types of clutches.

It is customary to build internal bearing walls with a thickness of 1 brick, and partitions intended for dividing the room into smaller ones are laid with a masonry of 0.5 bricks, in addition, foam concrete and aerated concrete can be used for partitioning. To increase the rigidity of the walls, as a reinforcement reinforcement in the joints are placed ordinary wire.

roof erection

For a bath you can use a saddle or gable roof. A single-pitched roof is a simple device and requires a minimum amount of materials when manufacturing it. If the bath is attached to the house, then a roof slope is installed.

The gable has a complex construction, much more material and labor is required to build it, but it looks more aesthetic and there is room for attic equipment. The larger the angle of the roof slope, the less snow will remain on it, but the roof sail and the volume of the attic increase. Just like the walls, the roof is protected by steam, heat and waterproofing.

As the roofing is currently used a variety of materials: from roofing material to shale and copper coating. To inexpensive rolled and sheet roofing materials can be attributed ruberoid, slate, corrugated board, Euroshield. On the basis of the price / quality ratio, Euroshift is in the first place among inexpensive materials, it has a low weight, rich colors, long service life and easy installation.

waterproofing, thermal insulation and vapor barrier

Brick and concrete, especially those in contact with the soil, absorb the moisture perfectly, which in the end leads to its destruction. Therefore, to improve the reliability and durability of the building, it is necessary to perform high-quality waterproofing.

There are different options for waterproofing. You can use special additives in the cement slurry, which reduce the moisture absorption of concrete. Another method allows to perform foundation protection by creating an additional waterproofing layer on its surface.

As waterproofing, bituminous and polymeric mastic, coating waterproofing, penetrating waterproofing, sprayed liquid rubber, melted bitumen can be used, which, depending on the consistency, are applied to the surface to be protected with a brush, spray or spatula. In addition, rolled and sheet materials are widely used, which can be fused with a gas burner, fixed with a self-adhesive film or otherwise. After the concrete hardens, the foundation for waterproofing can be simply covered with a roofing material, glued and sealed with bitumen. For protection is also used plaster waterproofing with the addition of special components that penetrate and fill the pores in concrete and brick.

It is very important for a good bath to maintain a constant temperature and humidity regime. For a vapor barrier, a film that does not pass moisture is used: polyethylene, glassine or aluminum foil. The seams are sealed using aluminum foil and adhesive tape. On top of the film is equipped with wooden lining, so it remains under the board and does not spoil the appearance. For vapor barrier insulation, materials based on foamed polypropylene or kraft paper with a layer of foil applied are also successfully used.

For a bath of brick it is extremely important to perform reliable thermal insulation. The loss of heat through the walls can be from 20 to 30%, through the underground part of the building - up to 20%. In order to reduce these losses, the walls and the foundation are warmed. Most often, because of the low price, polystyrene or mineral wool is used. Polyfoam is very easy to install, has good insulating qualities, however it is flammable and extremely short-lived, its lifetime is incommensurably smaller than that of brick and concrete. Mineral wool has a worse thermal protection than polystyrene, and due to the penetration of moisture into the material over time, the thermal conductivity can increase to 50%. But cotton is very resistant to chemicals and high temperature.

It is desirable to produce insulation with heat-insulating materials that can retain their properties when exposed to moisture. One such modern material is extruded polystyrene foam. It allows you to perform both thermal insulation and waterproofing. Extrusion foam polystyrene has low coefficients of thermal conductivity, water absorption and vapor permeability, high compression strength, and at the same time a long service life. In addition, it is resistant to the effects of microorganisms, easy to process and install. This material can be used to insulate the base of the building, the blind area, the foundation along the perimeter, the floors, the roof, and also the facade, followed by protection with plaster. Depending on the type of wall, thermal insulation sheets can either be glued to the surface to be protected or fixed using dowels.

Another of the modern high-performance thermal insulation materials is foam glass, which is a foamed glass. It does not pass moisture and water vapor, does not burn, is environmentally friendly, retains its properties for a long time.

Massive thermal insulation, such as mineral wool, polystyrene, glass wool and others, successfully replaces reflective insulation with or without an adhesive layer. When installing, it is worth considering that the reflective layer of the coating should be directed towards the source of heat.

For thermal insulation foam from polyurethane can also be used. This material has high thermal insulation properties, is formed by mixing the two components, and their foaming occurs. Foam increases in volume, filling all kinds of cavities and cracks, after which it hardens. Polyurethane foam is better than other materials for sealing, but there are significant drawbacks to this material: polyurethane is very flammable, detrimental to solidification, short-lived, relatively expensive, special equipment is required for preparation and application.

communication

At the design stage, the bath should provide for how the water is connected to the construction, where the sewerage will be connected, and how to provide electricity. Concrete drilling with a large diameter is quite laborious work, so if it is planned to lay pipes through the foundation, when installing the formwork it is necessary to lay hollow sleeves in the places where the sewerage and water supply pipes will later pass. When choosing the diameter of the sleeves, it must be taken into account that the pipes will be laid with thermal insulation.

As the sewerage and the water pipe enter the building through the foundation, their wiring must be carried out before flooring, as then access to communications in the underground space will be absent.

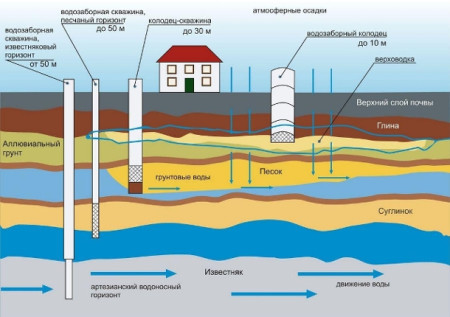

For draining used water, the ideal solution is to connect to existing communications. If the bath is erected at the dacha, the sewage system is most likely to be absent. At a site where the groundwater level is low, you can equip a simple drainage pit. To do this, at a distance of 2-3 m from the bath, excavate the pit with a depth of about 2 m, pour a layer of sand and a layer of crushed stone with a total thickness of 15-20 cm to the bottom. A large metal barrel with holes cut in the side wall can be used as a recess . The tank is placed in the foundation pit and a sewage pipe going at an angle from the bath to the pit is lowered into it, the pipe is inserted into the hole made in the top cover. The space around the barrel is filled with gravel and everything is covered with soil. It should be noted that the drainage pit is designed only for liquid. There is a way to equip a waste pit using old tires, where the tanks are stacked on top of each other, in which holes are cut. Tires from the car have a small size, so it is better to use tractor.

It is good, if drinking water is supplied from the centralized water supply system. In its absence, an alternative source of water may be a well or an artesian well. Drinking water after natural cleaning is at a considerable depth, so it will take considerable cost to find quality water. It must also be taken into account that not always water from the well or well corresponds to the sanitary and hygienic norms and it will be necessary to bring it to the norm with the help of filters.

During frosts, permanent heating of the premises should be carried out, otherwise the remaining frozen water can break the pipes. The layout of water in the bathtub should be made with plastic or polypropylene pipes, their installation is not difficult and they are less susceptible to tears in case of freezing. For winter, the water from the system should be drained, and pipes on the street should be equipped with thermal insulation and an electric heating system.

Electricity for a large bath is a must. Electricity can be supplied to the building by underground or air. The easiest, fastest and cheapest will be air-line equipment with the help of a CIP wire specially designed for this purpose. The length of one span must be up to 15 m, and the wire to the building is inserted at a height of not less than 2.75 m. The SIP conducts only the air passage, and the wire must be of a different type. For laying a subterranean line, an armored cable is used and a trench with a sand pillow is required.

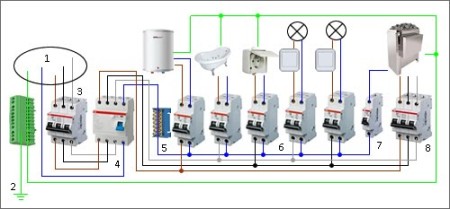

Correctly, if the power plan of the sauna will be a specialist. In the premises of the bath very high humidity, so they are subject to increased demands. The power scheme should take into account a number of factors: the number of rooms, locations, the number and power consumption of electrical appliances, etc. In any case, in rooms with high humidity there should not be outlets and switches. It is better, if in these rooms low-voltage fixtures will be established, and their power supply will be included through the step-down transformer.

The power supply must be turned on by means of a common circuit breaker, which is triggered by a short circuit in the subsequent circuit. After the machine, a residual current device (RCD) must be installed, which instantly disconnects the power supply if the person is exposed to dangerous voltage. The operating current of the RCD is better to be selected within the range of 25-30 mA, since with a smaller current, false alarms are possible. Automats and RCDs are mounted in a waterproof switchboard near the entrance door, the shield itself must be securely protected.

Consumers of electricity are grouped by capacity, purpose, location. Each direction is also protected by a circuit breaker, only designed for a smaller current. Inside the bath can only use copper wiring, the cross-section of the wires must be selected depending on the power of all connected to the chain of consumers with a margin of 20-25%.

Lamps in the bath are installed in an airtight version with high-strength heat-resistant glass. It is best to mount the wiring in corrugated pipes, plastic cable ducts and plastic skirting boards with a cable duct. The passage of the wire through the wall must be carried out in a metal pipe. Wiring must be done by soldering or by means of special terminals.

interior finishing of a brick bath

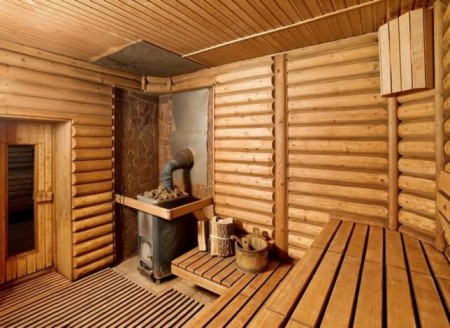

In the steam room for sitting and lying there should be at least two or three shelves. The air between the ledges of the shelves should be circulating, so leave a gap of at least 30 mm. The boards should be carefully cleaned to avoid splinters. The width of the shelf, intended for sitting in the steam room, should be at least 0.4 m, for sitting with raised legs - 0.9 m, and the distance between the shelves in height - 0.3-0.45 m. To an adult can calmly get up from the top shelf, the distance from it to the ceiling should be made at least 1 m. Stone and brick very much burns the human skin, so it is desirable to make the interior of the steam room with wood. The ceiling can be covered with a board 2-3 cm thick, and the walls - with a lining. For the floor, you can apply boards or floor tiles. It is necessary to know that the wood darkens from the high temperature and humidity - this is considered quite normal. In rooms with high humidity conventional nails are corroded, so it is necessary to use nails covered with a layer of zinc or copper, or other fasteners made of stainless metal.

The shower, as well as the steam room, is susceptible to mold formation, and must be protected against moisture. It is desirable to finish the floor and walls from ceramic tiles with increased moisture resistance. In order for the used water not to form puddles in the shower, the floor must have a slope toward the drain hole.

When you visit the sauna b aboutmost of the time people are in the waiting room. As a rule, this premise is combined with a rest room, therefore it is necessary to worry about their furnishing especially. Most often, wood is used for decoration - it is beautiful and keeps heat well. Good on the floor will look ceramic tiles, but we must immediately be prepared for the floor to be cold. The choice is left to the owner of the bath.

Hot water in a bath is simply necessary, for which it is more expedient to use an electric storage water heater. If a small bath is being built, then a 50-liter boiler may well suffice, with a large number of guests - from 100 liters. The flow-through water heater is more compact, but it has significantly more aboutthe higher the power consumption and will require the use of large wiring.

external finishing of the bath

Construction, as a rule, ends in external finishing, after which the building gets a complete look. The brick building itself looks good and therefore does not need any decoration. Often, the facade is simply protected with plaster, followed by painting with facade paints. The disadvantage is that with time the plaster crackles, and the paint has to be renewed, but the cost of such finishing is not high.

If the owner builds once and for a long time, a very good, but expensive solution will be the use of clinker tiles or porcelain stoneware. These types of tiles are specially designed for heavy-duty operation and are able to withstand the constant impact of such natural factors as precipitation, temperature changes, sunlight and ultraviolet radiation. Ceramic granite has a very dense structure and in winter, when laid on cement mortar, it falls off, that's why special adhesive compositions are used for porcelain stoneware.

Very beautiful looks the facade, lined with natural stone, however, the stone has a very high weight and therefore the building must be designed for additional load.

Completely transform the building is capable of siding - finishing material in the form of panels of metal, vinyl, fibrocement, ceramics, designed to protect the facade from the effects of the environment, and to give the structure a final look. It has special locks, with which the panels are fastened together. A special socle siding is designed for increased loads. Installation of the siding is not difficult and you can finish the building in a few days.

useful tips

- so that the liquid solution does not leak through the cracks of the formwork, it is recommended to protect it, for example, with polyethylene film, ruberoid, etc .;

- on the inside, the formwork must have a smooth and smooth surface;

- concrete when heated solidifies and can crack, so it must be cooled with water;

- the door from the steam room should open outwards so that a person can leave the room quickly, if necessary;

- wood is a combustible material, so it must be treated with flame retardant;

- in the sauna room it is desirable to have fire extinguishing means;

- if the floor tiles are cold, you can put wooden gratings on top of it;

- for interior decoration it is not necessary to use chipboard and fiberboard plates, as they are jammed in high humidity conditions;

- premises with high humidity should be equipped with a forced ventilation system;

- automatic switches are recommended to mark, in case of need to quickly disconnect the load.