Many houses have a basement. You can not leave it open, it's best to cover it with a lid. For a more aesthetic look, you can buy a ready-made hatch in the building store or make it yourself. We'll tell you how to do this in this article.

Content

Floor hatches, what is it?

Often in the houses the entrance to the basement is from the rooms. The hole in the floor looks not aesthetically pleasing and unsafe for tenants. Therefore, it is best to close the entrance with a floor hatch. This sturdy construction is usually made of steel and flush with the floor. And it can be outside with the same material as the floor in the room.

The advantages of this design include:

- strength;

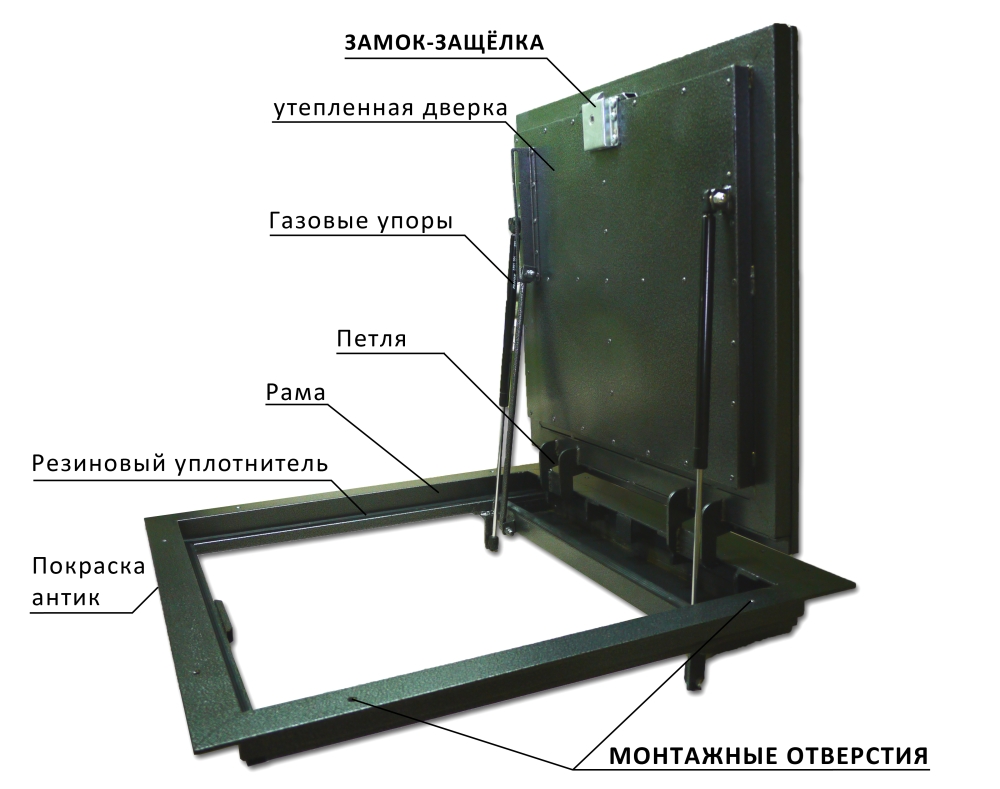

- special latches securely hold the hatch open;

- the presence of shock absorbers in the structure facilitates the opening;

- seals make the lid hermetically sealed and prevent the penetration of dust and dirt;

- the lock will close the lid and prevent unauthorized access to the basement;

- the design despite the apparent massiveness is content with the light;

- acceptable price.

This option of closing the basement is convenient and will not spoil the appearance of the room.

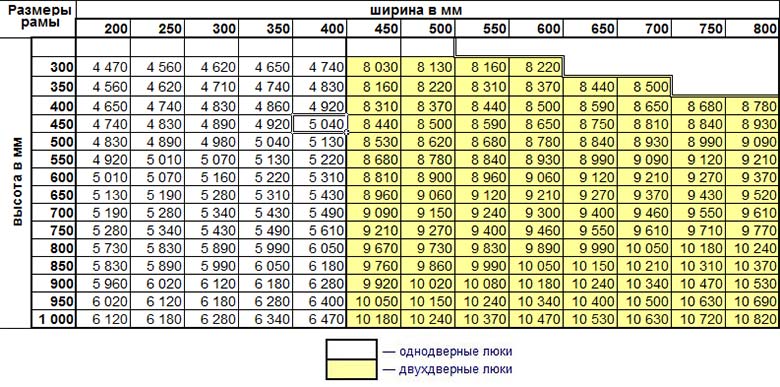

Floor hatches sizes

Hatches outdoor can be standard and non-standard sizes. To the standard one can include models with a width range from 60 to 100 cm, and lengths from 30 to 200 cm. When purchasing a finished product it is enough to come to the building store and choose the most suitable size from the presented. Custom hatch can be ordered from the manufacturer. And the house can come zamerschiki, which will prompt you the optimal size for your product and its best location. Such a product can cost more, but it will be manufactured taking into account the floor material.

Methods of manufacturing floor hatches

Depending on the appearance and method of opening, manholes are manufactured with gas shock absorbers and without them. Shock absorbers make it easy to open the door and hold it in this position. It's quite convenient to use. In addition, the hatch cover can simply be removed from the floor. This design is usually made for ceramic tiles. It will be necessary to make efforts to open the underground.

Materials for the manufacture of floor hatches

Materials for the manufacture of such products are most often metal (steel, aluminum). Now it is popular to make an exterior finish under the floor covering. Therefore, to this list, you can safely add and floor coverings (linoleum, carpet, laminate, etc.). You can also make a wooden hatch. As you can see the assortment is large and will allow you to choose the best option for each specific case.

Variants of floor hatches

It would seem that it can be simpler than such a device as a floor hatch. But here there are some nuances. They can be supplied with various mechanisms.

In general, hatches are divided according to the type of opening of the lid on:

- hinged - removable - equipped with a removable cover, and on the outside of the frame comes a rubber seal, are made mostly of aluminum;

- hinged - pushing on hinges - the lid is fixed to the frame with hinges, to open it you need to press the hatch itself;

- hinged - filled - in the lid there is a groove filled with concrete for weighting; in the opening mechanism, hinges and shock absorbers can be provided in such a hatch;

- hinged with a corrugated lid - it is not designed for exterior finish, its surface is anti-slip, and it is scraped off with a special key.

Now you know what hatches can be and choose for yourself a more optimal option.

Hatches floor with shock absorbers

For more convenient opening and holding the cover, shock absorbers are used. Most often these are gas varieties. They are used with metal hatches, which have a large mass. The advantage of using shock absorbers is the installation of a vacuum lift instead of a handle. So the hatch will become invisible on the floor.

Floor hatches in the basement

In most cases, the entrance to the basement in the form of a hole in the floor does not look aesthetically pleasing. And most of the owners dream of closing it with a lid. Now with this there are no problems a lot of firms are engaged in their manufacture. You can make it to order, but it will be many times more expensive. Therefore, you should not rack your brains. Now consider the main options offered to the consumer.

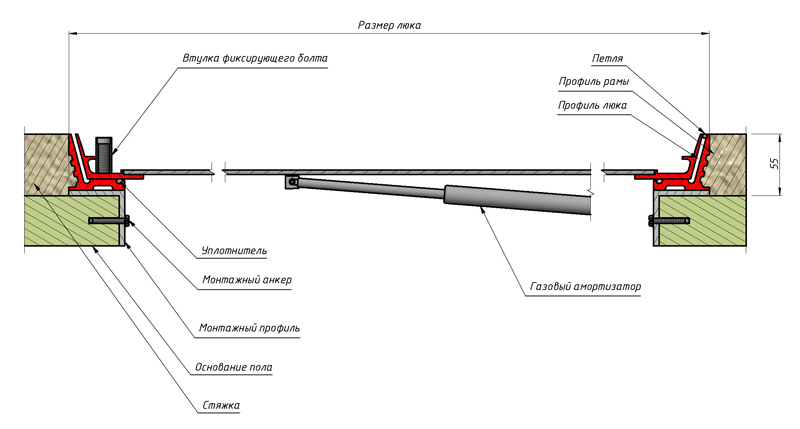

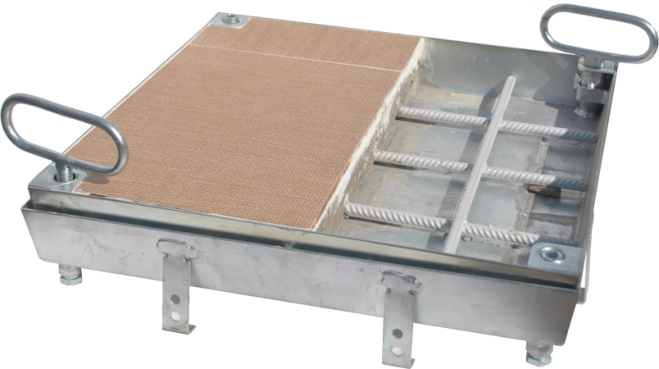

Aluminum REVIZOR LIFT for wet rooms. Manufacturers took into account the easy opening and fitted the hatch with gas lifts and hinges. Dimensions of such products begin with 60 × 60 cm, the maximum width is 150 cm. Such a hatch is designed for tile flooring, so it has reinforcement made of reinforcement with a cross section of 8 mm. The design includes a landing bed for installation and a trough for final finishing. The lid is provided with a seal for tightness. The total height of the frame will be 5.4 cm. It should be noted that when installing the hatch in the initial size, we finally get an opening of 50 × 50 cm. The finished lid will weigh 30 kg and open easily.

Reinforced STEALTH Thermo. This brand is on the market for 3 years and is engaged in the sale of low-cost models for home use. It is able to withstand a load of 200 kg / sq. m. In addition, there is a seal and a lid insulation. This is especially true for the basement hatch, tk. it's pretty cool. This will save you from heat loss. Own production and painting chamber allow the firm to keep democratic prices for its products.

It is best to purchase finished products where everything is calculated and provided by engineers.

Floor Invisible Hatch

Yes, these too are. There is nothing mystical here. The lid is simply made with a recess. It is then poured concrete and laid tiles, or mount a laminate. Let us consider these models in more detail.

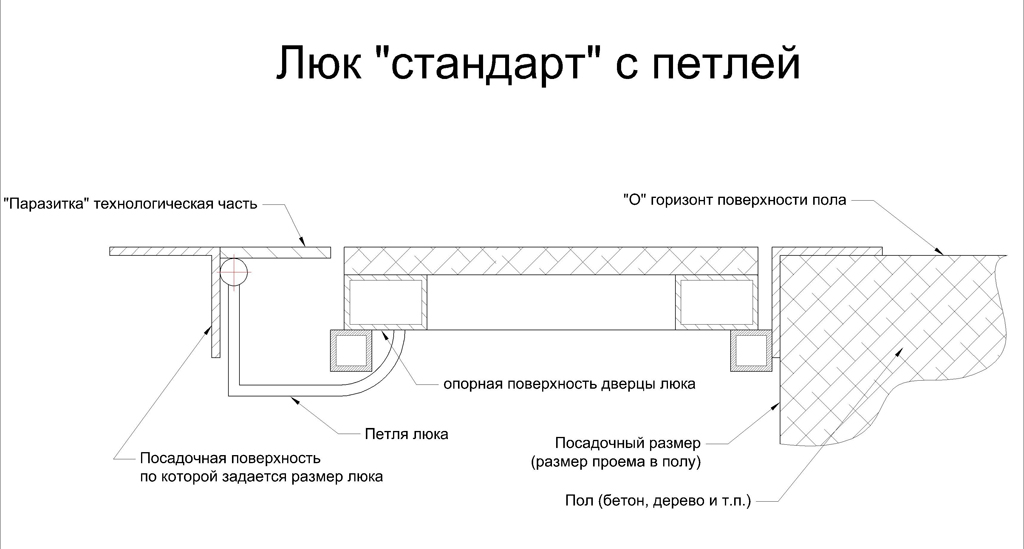

tilt hatch

Many have access to the cellar from the kitchen or hallway. The most optimal floor covering for these rooms is a tile. It means that it must be present on the hatch cover. So it will be invisible. You can order a similar product or make it yourself.

To do this you will need:

- a corner of steel;

- sheet steel thickness of 3 mm;

- reinforcement cross-section 3 - 4 mm;

- tile and mortar.

From the tools you will need:

- angle grinder with a disc for metal;

- screwdriver;

- roulette;

- welding machine.

From the steel sheet, we cut out a piece of the corresponding lid. On the perimeter weld the corner, forming the side. After that, we weld the reinforcement inside to form the cells. After that, from the corners make a frame of the hatch and heat it in concrete. And its width should coincide with the width of the lid. Using the hinges, attach the hatch cover to its frame. Now you can start finishing. We mix the solution and fill it in the lid. After that, we lay the tile. It should be ensured that the seams on the floor and lid match for an integral picture of the floor. This way you will get a reliable cover for the subfield.

floor hatches for laminate

If a laminate is laid in your house on the floor, and the hatch is made necessary, the best option is a lid with a laminate. So you save the visual integrity of the cover and make the entrance to the sub-floor more functional. Such a model can be bought ready-made, and you can do it yourself.

The sequence of work is as follows:

- we remove the exact dimensions of the opening in which the hatch will be mounted, including the thickness of the slabs;

- make the drawing of the hatch taking into account the recess under the cover, it must correspond to the thickness of the layer screed - substrate - laminate;

- weld the frame and attach shock absorbers to it;

- try on the opening and eliminate unnecessary gaps;

- after that the construction is cleaned of dirt and rust, primed and painted;

- after drying, we make a screed, fix the substrate and already glue the laminate to it.

All this is done with the lid closed. After that, open it and remove the remnants of the solution. After that, fix the lifting mechanism and seal the hatch. That's all, the hatch is ready. And the main thing is completely unnoticeable.

This article describes the floor hatches. Their types are given. Tips are given for the self-manufacturing of invisible models. Using the information of the article, you can close the entrance to the basement with a reliable and warm hatch, without spoiling the appearance of the floor. Successful work.