With the arrival of the first spring days many people have an irresistible desire to go to nature to cook shish kebabs. In principle, for all, this sortie takes place according to an approximately identical scenario. First, a good company is going to. Then, a sufficient amount of fresh meat is selected and bought. Then it goes through the process of marinating (and everyone uses their long-proven recipe). The next most pleasant and quivering moments are stitching of pickled meat on skewers and building a fire. And, at last, directly process of frying on the heated coals, on a brazier.

Content

- 1 Types and varieties of braziers

- 2 How to calculate the size of a brazier

- 3 How to make a brazier out of a barrel

- 4 How to make a non-separable brazier with your own hands from a sheet of metal

- 5 How to make a folding BBQ with your own hands

- 6 How to protect the brazier from corrosion

- 7 How to make a brick mangal with your own hands

- 8 How to make a beautiful brazier

Types and varieties of braziers

Usually (standard), the brazier looks like a box of metal on the props. On the walls of the box are marked cavities for placing skewers in them. Depending on the size, the barbecue can be divided into two main types:

- portable;

- stationary.

Often, fixed barbers are built on household plots. Not infrequently they are decorated with elements of forging and stone furnish, and also mount on the basis of a brick. The presence of such a decor will give refinement and uniqueness of any design. Ideal for operation will be the options for placing the barbecue in the gazebo or under a canopy. These options will allow cooking almost in all weather conditions.

Basically portable mangals are in demand among companies used to spend their holidays in nature. First of all, they are convenient in that they have relatively little weight and compact dimensions. Also in specialized stores you can find portable mangals sold already packed in small cases made of metal. This in turn simplifies their transportation.

In order to produce the most primitive mangal model will not need much at all. Completely enough is a couple of frames made of metal. After they are mounted in the ground, you can put skewers with strung meat. A significant drawback of such designs is the lack of the ability to prepare at the same time a sufficient number of portions per large company.

There are models that are also considered portable, but have much more weight than described in the previous version. They are more convenient for traveling to nature using personal vehicles. They are arranged a bit more complicated. The presence of additional grilles, regulating blowers and a small table, which, if necessary, advances, greatly simplifies the preparation of food.

Depending on the thickness of the metal used for manufacturing, the braziers can be thick-walled or thin-walled. Naturally, thinner sheets have become used in the manufacture of portable models. But minimizing the thickness of the metal leads to short-lived construction. In such models it is desirable to use prepared in advance or purchased coals. When trying to cook coals in such a brazier, the walls will burn very quickly.

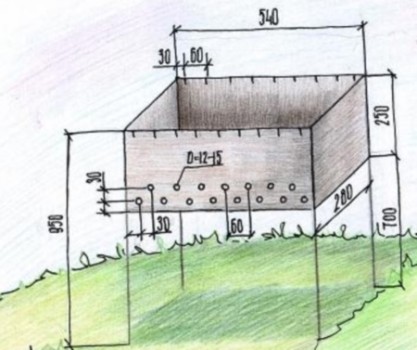

How to calculate the size of a brazier

To build a brazier of optimal size, you need to consider how many servings of shish kebab usually need to be cooked for a feast. If the number of people is limited to three or four, the size of the brazier can be 300x600 mm. At the same time, the width of the product is calculated from the considerations that usually 10 pieces of meat are squeezed onto the skewer, which occupies about 30 cm of the length of the skewer. Making a wider brazier makes no sense - this will cause unnecessary heat loss.

If the brazier is supposed to be installed in advance, grilles should be taken into account.

If a large company usually gathers, then the calculation should be based on the number of skewers that need to be placed simultaneously. The distance between them should be of the order of 10 cm, along the edges should also be added 10 cm on each side. But while the dimensions should be limited to the size of the trunk of the car.

In order not to burn it when cooking shish kebab, but the temperature at the location of the skewer was high enough, the depth of the brazier should be from 15 to 20 cm. The high height of the rims will require an increase in the number of coals.

The height of the legs is determined experimentally, by measuring the distance from the floor to the level at which it is convenient for the hands to perform the actions for preparing shish kebab.

The optimum thickness of metal is 2 mm. The thinner one will serve very little, the thicker one will lead to a serious weighting of the product. Processing of thick metal can also cause difficulties.

How to make a brazier out of a barrel

Although traditionally the brazier has a rectangular cross section it is quite possible to build it yourself from an old metal barrel or a gas cylinder. It is not desirable to use for this purpose barrels from under lubricating and combustible materials. It is preferable to find a container with thick walls - this will significantly extend the operating time.

In addition to the barrel, you will need:

- welder,

- drill and bulgarian,

- corners of metal.

First, on the surface of the tank we make a marking, we cut off the top half with the help of the Bulgarian. At the same time, we leave the ends in place. The cut part is not thrown away - you can make a lid from it. To make the legs you need corners - they need to be cut into the same lengths and welded to the end.

From the cut pieces of a corner of equal length a support for the skewers is constructed. At the corners of the incisions, the places for placing the skewers should be indicated, the incisions should be made at a distance no less than 5 cm. Next, the pieces of the corner are welded to the inner surface of the barrel.

If we weld metal hinges and handles to the cover, we will get reliable protection of the contents of the brazier from the rain.

How to make a non-separable brazier with your own hands from a sheet of metal

For work you will need to prepare:

- a metal sheet,

- corners or rods for the manufacture of legs,

- welding machine,

- bulgarian,

- drill,

- hacksaw for metal.

To simplify the work, you will need to complete the drawing. It is better for him to take a millimeter paper or a sheet in a cage. An unassembled construction will consist of walls connected at right angles, bottom and legs. These parts will need to be prepared before you make a brazier, the dimensions of each part should be indicated in the drawing. It should be determined with the length of the legs (determined individually), the dimensions of the brazier itself, indicate the location of facets for skewers. Usually they are made 8.

On the walls it will be necessary to make a perforation for venting the bottom. The optimal distance between the holes is about 8-10 cm, it is better to arrange them at a height of 5 to 10 cm from the bottom of the brazier.

Further, in accordance with the drawing, the bottom and walls are marked on the steel sheet. Its minimum thickness is 1.5-2 mm. If possible - metal is desirable to use thicker.

Cutting the metal can be done by a Bulgarian or a hacksaw for metal. A drill is used to perform the perforation. At the top edge of the future walls on the marks, we make incisions for fixing the skewers, for this you can use a hacksaw or a Bulgarian. Then you can start welding work - connect the walls between each other and weld them to the bottom.

One side of each of the future legs is cut so that an acute angle is obtained, this will make it easier for the metal rod to enter the ground. Then, by welding, the rods are attached to a metal box. If the legs of the barbecue are long, then to make the structure of greater strength it will be necessary to connect the legs with bridges.

If there is a need for the legs to be demountable, then nuts are welded to the corners of the bottom of the box, and threads are cut at each of the legs with an appropriate step. If necessary, the legs can be unscrewed.

How to make a folding BBQ with your own hands

If there was an idea to build a collapsible brazier from metal, then it is quite possible to do without welding works. From the tools you need:

- drill,

- a Bulgarian and a hacksaw for metal,

- nuts and bolts,

- roulette,

- steel sheet thickness of 2 mm,

- corner made of metal for making legs.

Starting work follows from the execution of the drawing and the preparation of the details of the structure. With the help of the grinder, a marked sheet of metal should be cut, but to complete the dismountable structure, add 3-4 cm to the joints. Then, the edges of the cut out fragments should be bent so as to allow the angles to be joined and the bottom to be laid, and screw holes are made in the side edges. The feet are also fastened with bolts.

According to the design, the unseparable and dismountable braziers are very similar, they both have a rectangular cross-section, the only difference is in the assembly method - the first is assembled by welding, the second one by bolts. The main advantage of the collapsible structure is its mobility and compactness, ease of transportation.

How to protect the brazier from corrosion

To make a thing of metal serve as long as possible, you should take care of its protection. For this, it is possible to use heat-resistant aerosol paints sold in auto shops. The second option is a change in the structure of the metal with the formation of a heat-resistant film on its surface. Burning of metal is made as follows:

- degrease the surface,

- withstand parts for an hour and a half in a solution of caustic soda, for each liter of water it is taken 50 gr.

The metal is treated at a temperature of 140 ° C.

How to make a brick mangal with your own hands

If the owners of the suburban area often invite guests or gather the whole family for barbecue, then the rational solution is to build a brick brazier. The place for it should be chosen such that:

he did not interfere with the work that is usually performed on the site,

it was easy to build a roof over it, which would eliminate dependence on natural factors, in particular, snow or rainy weather,

near it there was a water source.

The cheapest and most affordable material for the construction of a stationary barbecue is brick. It keeps the heat well, its service life is long enough, it is not corroded and does not burn out from exposure to high temperatures.

At the selected location, first mark out the contour of the future structure, then dig a ditch under the foundation. Since the planned construction will not have a very large weight, the foundation for it will be the simplest. The ditch can be lined with a ruberoid, covered with a five-centimeter layer of sand, then with a mixture of gravel and brick battle, pour all with a cement-sand mortar. To mix the solution, you can use any old metal trough, with a small amount of the prepared mixture, you can do without a concrete mixer. An important condition for building a quality foundation is to maintain the same level in the whole area. It is not difficult to do this - you can use the usual building level.

Bricks before laying should be properly moistened. You can pour them on the eve with water, you can soak in a bucket of water already in the process of doing the work. In any case, it is not recommended to put a dry brick.

Particular attention should be given to the laying of the first row - it should be even. The next series is in staggered order. The correctness of the laying of each row is required to be checked by level and plumb. At the level of 4-5 rows, thick metal rods should be laid between the walls - they will be required for arranging the brazier.

That the precipitation does not prevent pleasant cooking on the grill, it is desirable to build a roof over it. For it, you can use a sheet of roofing iron. If there is a possibility, then also protect the construction from the wind at the sides.

How to make a beautiful brazier

To be more precise, how to improve a brazier - after all it will be in the center of attention of visitors and owners of a site, going to have a rest and попить. If the remains of bricks were used for the laying of the brazier and the masonry was not very attractive, then the brazier can be clinker brick or tile.

Often the owners of the plot build a brick brazier combined with a street wood stove, creating a whole kitchen complex. The choice of the original design and its high-quality finish will make the device for cooking a real piece of jewelry.