The abundance of photos and descriptions of heat-insulating materials on the Internet allows you to professionally produce insulation of the ceiling and roof of a private house. Here, even think is not particularly necessary: took a plate of mineral wool and laid between the rafters. But the seeming simplicity is deceptive, because the insulation works are considered the most laborious and complex. We'll have to work hard, starting with the right material selection and installation.

Content

Insulation for the ceiling of the house - loose, roll or plate

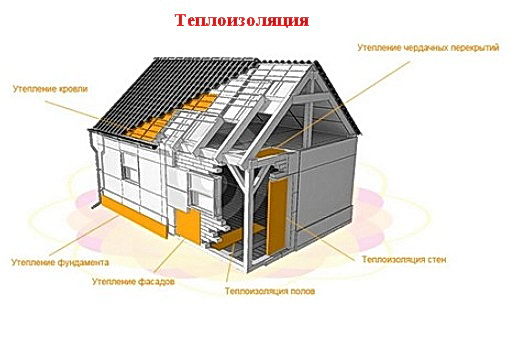

The main problem that every owner of a private house encounters is heat insulation measures, including the thermal insulation of the ceiling.

It is known that more than 60 percent of heat loss falls on the share of an unheated ceiling or a poor-quality insulation.

Warming the ceiling of the house must be given special attention, so

choose a ceiling insulation is necessary for a number of criteria:

• fire safety of the material

• Insulating properties (density and hygroscopicity)

• Simplicity and accessibility of carrying out self-assembly.

Thermal insulation materials are now abundant.

There are several technologies for insulation of the ceiling of a private house:

• using roll or plate materials (mineral wool, sheet polyurethane foam, expanded polystyrene)

• by spraying liquid polyurethane foam.

What materials are the Masters advising to make the insulation of the ceiling in the house?

Methods of thermal insulation of the ceiling

There are several ways to insulate the ceiling of the house:

• external method (with or without roof cover replacement)

• Insulation from the inside.

The option of external insulation is made from the attic, the under-roof space and the attic of the house. Naturally, this is a labor-consuming and costly way of isolation.

If you intend to insulate the ceiling from the inside, then the preference is better given to a mineral heater, made in the form of plates or a roll. A strong union with a suspended ceiling made of drywall will create a reliable barrier to leaking heat outside. Open the secret, if there is the possibility of external insulation, then this option is most preferable.

Thermal insulation materials: properties and possibilities

coefficient of thermal conductivity of materials, what is it

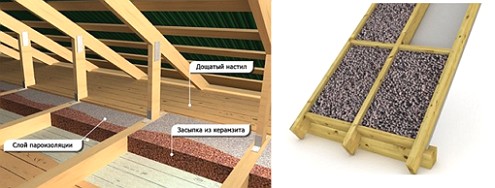

Several decades ago, slag and expanded clay were used to insulate the ceiling of the house, namely the attic space. The most successful thermal insulation material was claydite with a coefficient of thermal conductivity

λ = 0.18 W / (mK) and a bulk density of 800 kg / m3.

Working with a heater for the ceiling in a wooden house was easy: it was poured on the floor of the attic.

But gradually the expanded clay was replaced by more modern insulators: mineral wool, glass wool and expanded polystyrene.

The thermal insulation properties of mineral wool for the ceiling are higher, the coefficient of thermal conductivity is λ = 0.056 W / (mK) at a density of 100 kg / m3.

Ceiling surface with insulation with foamed polyurethane (liquid PPU) will provide a monolithic layer. The coefficient of thermal conductivity of the polyurethane foam is λ = 0.022-0.028 W / (mK). The speed and simplicity of applying the insulation makes it possible to produce insulation measures in a few hours.

Therefore, in order to find out which insulation is better for the ceiling of the house, it is necessary to make friends with the coefficient of thermal conductivity and to understand that the materials are conditionally divided into groups - vapor permeable and vapor tight.

Scheme of external thermal insulation of the ceiling

roll and plate heaters

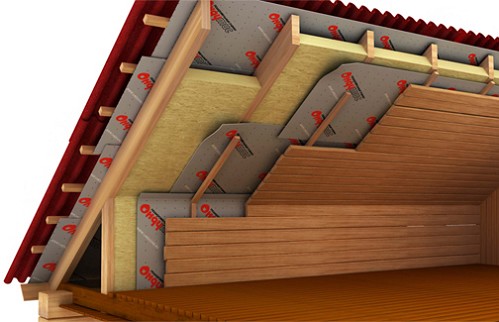

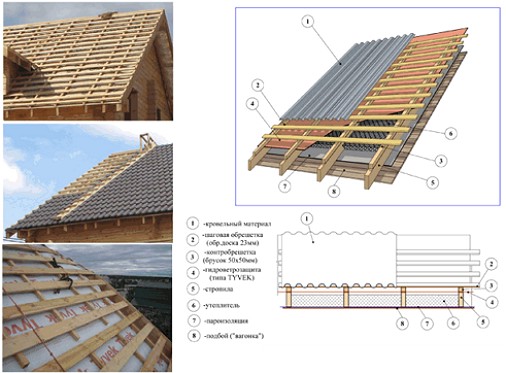

Let's show that the external thermal insulation of the ceiling of the house can be represented schematically from the layers:

• vapor barrier film

• roof truss system

• insulation layer

• Waterproofing film

• Roof carpet

• finishing finishes.

The option of external insulation of the ceiling can be made with or without replacement of the entire roof covering with the obligatory installation of a control box and a crate. To the slats of the counterbridge attach the waterproofing film, and to the crate - lining the roofing carpet and the finish of the roof.

Insulation of the ceiling from the inside

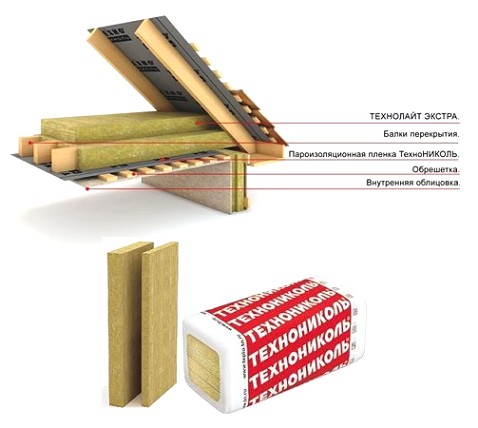

plate and roll insulation

The internal insulation has been exaggerated, it is possible to present under the scheme of external warming.

The difference lies in the mirror image of the insulation layers towards the interior space. Insulate roofing space roof and floor.

It is necessary to remember that it is recommended to install and lay heat-, steam- and waterproofing films taking into account the existing ventilation ports and openings.

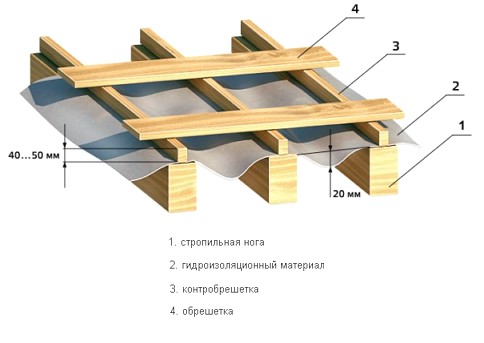

Warming of the internal roofing space begins with the installation of the crate and laying over the entire surface of the roofing system of the waterproofing film.

Fixing the film to a wooden structure is made using a stapler.

Thermal insulation material is selected taking into account the density of the material not less than 50-60 kg / m3. On the side of the roof, the insulation is protected with a waterproofing film, and with a vapor barrier membrane on the side of the house.

Plate or roll insulation is placed between the rafters in a staggered manner, ensuring a natural tight fit of plates and sheets.

An obligatory condition of installation is the width of the heater, exceeding the width of the rafter system by 1-2 cm.

After laying the plates of the heater, a layer of waterproofing is installed.

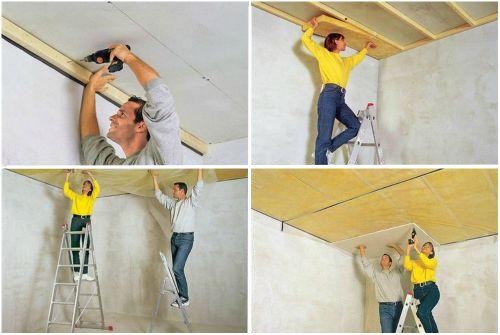

The final stage of warming is the internal covering of the ceiling with plasterboard or panels.

How to make the insulation of the ceiling of the house, shown in the video.

liquid polyurethane foam

A modern way to warm the ceiling of the house from the inside is to apply liquid polyurethane foam (PPU).

Applying PPU can reduce the cost of thermal insulation measures, because the material can be applied to any surface (concave or convex). Heater does not require erection of furring and control grills.

With the use of special equipment, the foam solution is applied directly to the surface, thereby reducing the load on the bearing beams. The methods of creating a heat-insulating layer are casting and spraying.

The technological nature of the method of thermal insulation with the use of liquid polyurethane foam is a promising direction.