To ensure that the heating system of your home is working properly with great efficiency, it is necessary, when choosing a gas boiler, to pay attention to the gas burner. Proper operation of the gas burner will reduce the financial costs, since a good burner will have a high efficiency and safety of the boiler. In this article we will consider the operation of a gas burner, analogues of which can be purchased on the company's website www.a-comfort.ru, since it is this device that makes up a combustible mixture of air and gas and supplies it to a boiler for combustion. A modern gas burner is universal, it can be connected to a gas main, to a gas cylinder or gas holder.

Content

Atmospheric gas burners

Atmospheric gas burners operate according to the principle of sucking air specifically from the volume of the boiler room.

The air from the boiler room mixes with the gas and forms a combustible gas-air mixture.

The gas-air mixture is ignited directly through the wick and a natural combustion process takes place in the boiler - in principle, we have a conventional household stove, so these boilers were called boilers with an open combustion chamber.

Thus, we have before us the most ordinary burners, which have become widespread in private houses and cottages.

Atmospheric burners have their advantages and disadvantages.

The advantages include:

- Noise (since no additional equipment is needed);

-automation of work (since it does not require electricity);

- Because the design is simple - it is high reliability in operation;

-minimum costs when operating the boiler;

- Minimum dimensions and minimum weight of equipment;

-minimum price of the boiler.

To the disadvantages of atmospheric gas burners, we can relate the following:

-dependence on gas pressure (at least 150 mm of water column) - which requires the installation of a gas pressure monitoring relay;

-to prevent clogging of the burner with dust, it is necessary to keep the air in the boiler room clean;

-low, below 90% efficiency;

-atmospheric burners can be installed on boilers with low power;

- Frequent burning of the burner nozzle, the possibility of burning the heat exchanger due to the pressure drop of the main gas.

Inflatable gas burners

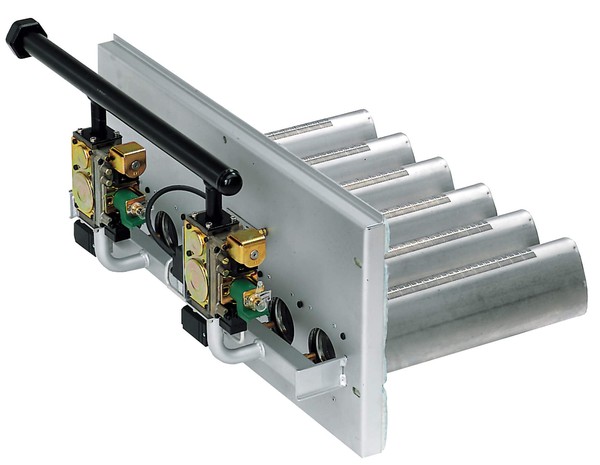

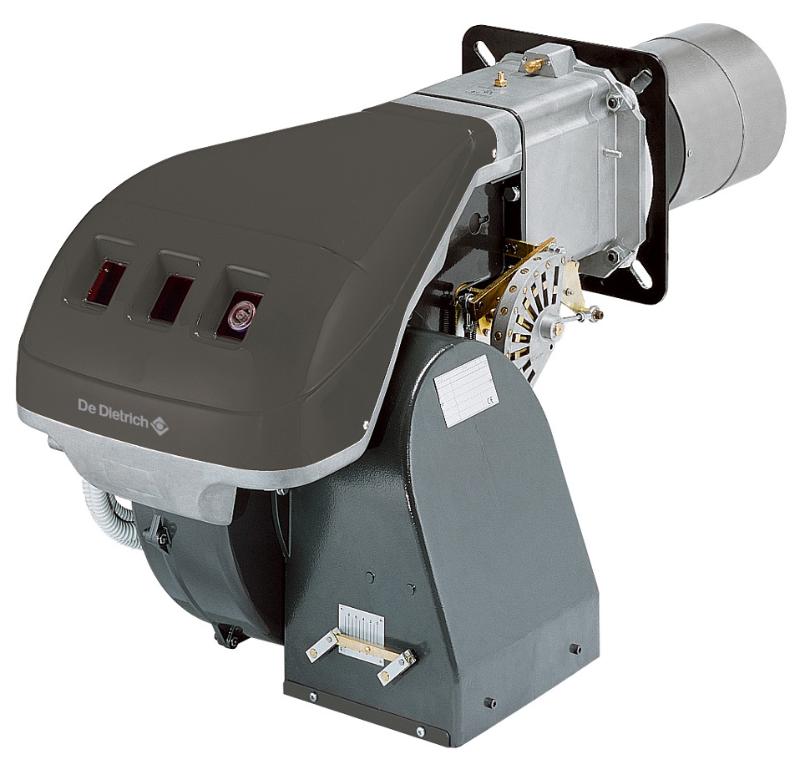

Burners of a supercharged type, in contrast to atmospheric burners, work by forcing air into the closed combustion chamber of the boiler with the help of an overpressure fan.

Using a special fan, the boiler is able to produce a flexible adjustment of the burner power - thereby increasing the efficiency of the boiler.

Burners of a supercharged type also have their advantages and disadvantages.

The advantages include the following:

- a closed chamber increases the safety of the boiler;

-more complete combustion of fuel increases the environmental friendliness of the work;

- As the burner is capable of controlling the power, the efficiency is increased to 95%;

-The work of the burner does not depend on the pressure differential of the gas main;

-The air burner is able to be selected at the request of the buyer, since it is hinged.

The disadvantages of the operation of the supercharged burners include the following:

- the operation of the boiler becomes noisy due to the operation of the pressurized fan, so the boiler room must be equipped with a good sound insulation;

- The equipment is heavier and bulky;

-more expensive price;

- As the boiler's operation depends on electricity, it is necessary to pay attention to the uninterruptible power supply;

- Expenses are increased due to electricity consumption.

Single-stage gas burners

Single-stage gas burners have the simplest design, so they can only work in one mode.

As soon as the boiler reaches the maximum temperature, the fuel supply switches off automatically, the burner shuts down.

When the coolant is cooled to a minimum - the automation switches on the burner.

Because of this step adjustment, there is a rapid wear of the mechanisms.

Two-stage gas burners

The operation of two-stage gas burners is automatic and depends on the thermostat.

The connected thermostat is able to regulate the operation of the boiler from a maximum power of 100% to a power reduction of 40%.

At the same time, a smooth power change occurs, convenient control of the boiler is obtained, fuel is consumed sparingly, thus the equipment is used more efficiently.

Analysis of gas burners

When purchasing a boiler, carefully study the possibilities of the presented designs, the corresponding capacity, simplicity or complexity of this equipment, compare the prices and only then make a decision.

You should know that gas burners must be regularly serviced - this work should be done by gas service specialists.