Warming the house from any material is an important stage of construction. How effectively is the house made of wood insulated, so the operating parameters of the structure will depend. Bypassing the external type of insulation means losing the attractiveness of the wooden frame. But internal insulation is not always able to provide proper comfort. How to act properly and choose the necessary method of warming?

Content

If the log house needs to be insulated

It is well known that wood is a good insulation. But over time, wood (logs or beams) changes geometric proportions and sizes, beginning to dry up, forming cracks and cracks.

Therefore, there is a need for warming the log house.

The ancient technology of warming the cracks between the logs with moss and paste is gradually becoming obsolete, giving way to more powerful warming multilayer systems. Theoretically, the house of logs or bars can be insulated both from the outside and from the inside.

The correct choice of type of insulation should be based on the use of "their" insulation. How to choose the material for each type of insulation and how to properly insulate the log house?

External insulation

There are many ways of exterior insulation at home. You can make a brick laying on top of the logs, or you can use siding and stenolith.

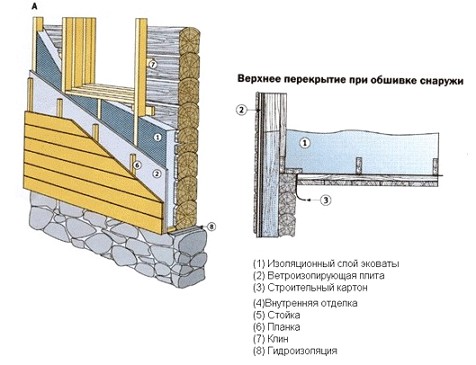

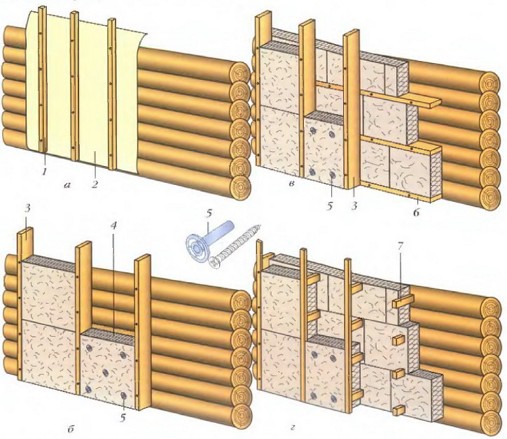

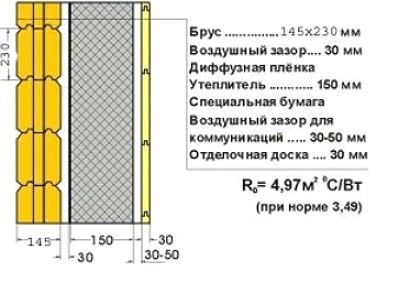

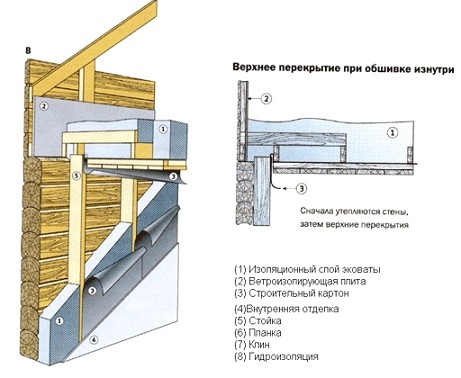

These methods are based on the technology of sheathing log walls with racks providing the ventilation. The subsequent installation of waterproofing layer and insulation allows you to easily insulate any wooden house from the outside. With external insulation, the thermal insulation material is laid between the rails of the crate.

Traditionally, stone mineral wool and expanded polystyrene are used for insulation. It is noted that the thermal deformation of wooden logs does not affect this type of insulation. In contrast to the internal insulation (first the walls are insulated, and then the upper covering), with the external skin only the facade and walls are insulated.

Warming of the log walls from the outside will consist of the following stages of work:

- erection of a wooden crate or carcass

- construction of a vapor barrier layer

- installation and fixing of a heater

- installation of waterproof membrane

- installation of a siding or stenolith.

To lay a vapor barrier layer on a smooth surface of logs, vertical bars are provided for fixing the film with staples, which is fixed with adhesive tape at the joints.

The boards of a wooden frame or a lath are beaten with ribs, creating a kind of clearance for ventilation. Laying insulation are made in the traditional way - insulation plates are placed between the slats.

Then install a moisture-proof membrane on the heater plates. In the lower edge of the membrane, a gap is left to remove the condensate. As an external cladding for a wooden house, preference should be given to the siding and stenolith.

Before choosing a heater, it is recommended to consult a specialist on the compatibility of the insulation with the material of the wooden house (log, bar). It will not hurt to look through the product catalog with the technical characteristics of the insulation.

The most popular are insulation from the manufacturer:

- Rockwool

- Styrofoam

- Isover

- Linerock.

How to make outdoor insulation of a private wooden house, shown in the video.

Internal insulation

The main methods of internal insulation of a wooden house are:

- technology of insulation of joints between joints of logs

- mineral wool insulation

- laying the vapor barrier foam foil

- use of oriented particle boards (OSB)

- application of a liquid insulation.

All types of outdoor insulation are available for hand-made execution.

Warmth "warm seam"

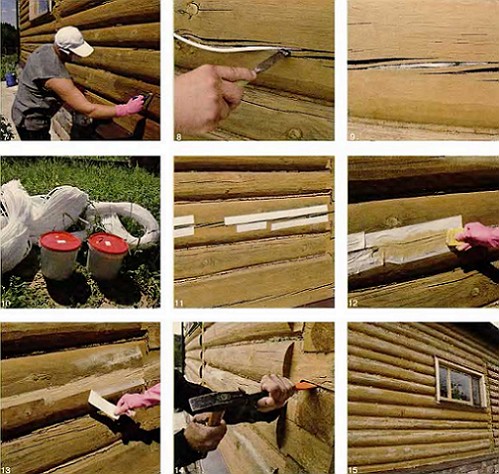

The technology of internal warming "warm seam" is based on the use of sealant, which is filled with joints between logs in places of intensive exploitation.

The sealant is a gel material or a rigid flexible sealant, when applied, a barrier is created for cold air, water and dust. Sealant or dense insulation is applied directly to the places of visually visible cracks or cracks, for example, sealing of cracks between the logs.

Application of liquid insulation

Liquid insulation and the way it is applied inside a wooden house is not yet in demand. The technology of applying a liquid insulation consists of layer-by-layer processing. This is the primary spray, the subsequent priming and covering the finish layer in two passes. Undoubtedly, this method of insulation is quite laborious.

We use mineral wool, OSB plates and vapor barrier

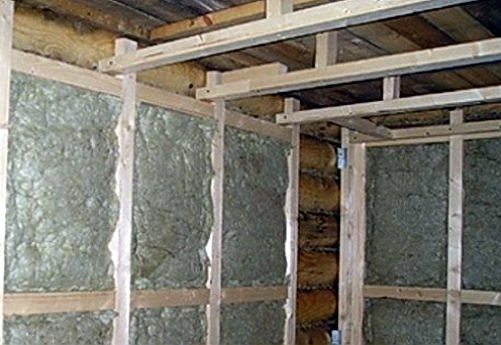

Classic internal insulation of a wooden house, using mineral wool, a vapor barrier layer and slabs, it is preferable to produce in a complex. This will ensure the insulation of walls, ceiling and floor, as well as an exhaustive answer to the tricky question: "How to insulate the house from the inside."

With this method of insulation, the construction of the enclosing structure is necessary. To do this, use a wooden bar, which is installed taking into account the chosen insulation. For the use of a mineral wool insulation for a close fitting, the distance between the bars is 10 mm less than the width of the insulation.

Width of the heater determines the step of installing vertical bars.

In some cases, the use of standard gypsum plasterboard profiles is acceptable. This choice will be justified solely for the finishing of plasterboard.

From all it is possible to draw a conclusion: insulation porous for an internal way of warming of wooden walls, a floor and a ceiling is recommended to cover from the party of a place with waterproofing films and a membrane permeable.

We make our own insulation of the house from the inside, as shown in this video.