Modern cabinet furniture firmly occupies a leading place in our houses and apartments. If you do not want to attract a designer, and decided to save money on building furniture, you can take any catalog of furniture and plan future furniture for your living room, hallway, nursery, etc. For beginners, the best option is to assemble a closet or kitchen. The kitchen and closet, in general, consist of cabinets and lockers of simple form. To avoid mistakes, when making furniture, carefully study this article, buy the necessary materials and get to work.

Content

- 1 Laminated wood chipboard (chipboard)

- 2 Cutting sheets of chipboard. How to close the cut edge

- 3 Facades for cabinet furniture

- 4 Material of the facade of furniture

- 5 Back walls and bottoms of boxes of cabinet furniture

- 6 Worktops for cabinet furniture

- 7 Assembling the details of cabinet furniture

- 8 Furniture fasteners

- 9 Furniture fittings

- 10 Furniture boxes and their guides

- 11 Doors for cabinet cases

Laminated wood chipboard (chipboard)

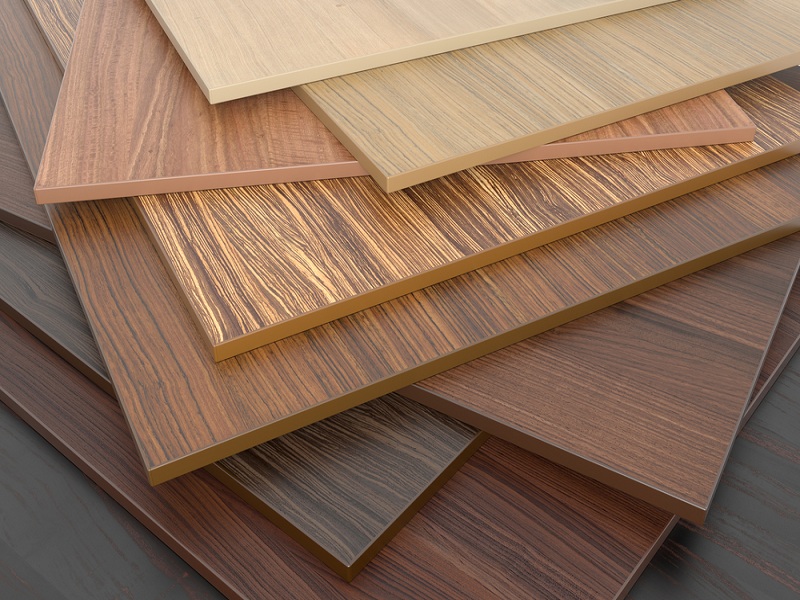

The main material in cabinet furniture is a wood-chip cooker. Modern material is not just a chipboard, but a laminated chipboard, i.e. ennobled. The thickness of this main material is 10, 16 and 22 mm. The thinnest, ten-millimeter sheets are used to fill the doors of the sliding-door wardrobe, the small thickness makes the weight of the product easier, especially since the load on the door of the sliding-door wardrobe is not particularly high. Laminated chipboard 16 mm, this is the main material in cabinet furniture, since almost all the components of this furniture are made from a 16 mm slab.

If you plan to make a bookcase, and as you know in the closet have a lot of shelves for books and on these shelves there will be a significant load, for such products use the thickest 22 mm slab. ЛДСП an excellent material for furniture, but if you plan non-standard furniture, you should cut up ЛДСП. And no matter how much you try to make cuts at home, the edge will always be chipped and uneven. Only special machines can make cutting perfect.

Cutting sheets of chipboard. How to close the cut edge

Since the chipboard is a very moisture-consuming product, naturally, the chipboard was asleep, the most vulnerable place. If you do not close it, the ends of the product will swell with time.

Edges come to the rescue, there are several types:

-Melaminovka edge, this is the cheapest edge, but of poor quality, with the help of an iron it can be glued at home to the saw;

- PVC edge, 0.4 and 2 mm thick. An excellent option for cabinet furniture, but can be glued only on a special machine. Therefore, take note and in the case of ordering cuts, make an order for the edge. If the edge is on the outer, visible side, use a 2 mm PVC edge. On remote, invisible ends, you can paste PVC 0.4 mm;

-AWS edge, edge similar to PVC, but is an environmentally friendly material;

-T-shaped mortise profile - fixed in a specially made, cutter, notch, not widely used;

-P-shaped patch profile, convenient to use at home, attached to liquid nails, if you received a poor-quality cut, when cutting the chipboard, the p-profile will hide the marriage.

The only drawback of the P-profile is that the edges protrude by several millimeters and dirt will fall under the P-profile.

Facades for cabinet furniture

If you are building a kitchen, the facade and doors are made of beautiful material, so the facade of the cabinet furniture should be in harmony with the room. If the furniture is non-standard, the facade is made to order, you should take into account that the non-standard facade can do a long time, count for 2-3 months.

If you are collecting standard furniture, you have to take into account that the facade, usually, is made 2 mm. less than the cabinet on each side. Proceeding from this, you should purchase furniture elements in the form of a facade less than a cabinet by 4 mm. For example, if the cabinet is 400 mm, the facade should be purchased with a width of 396 mm.

For information: the outdoor kitchen cabinet has a height of 715 to 725 mm (without legs). High hanging cabinets have sizes from 915 to 925 mm.

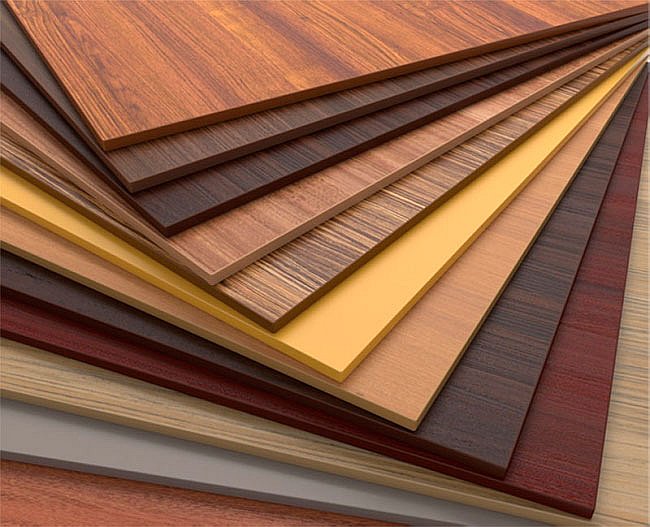

Material of the facade of furniture

The facade, in general, bears a decorative function.

Modern furniture facades differ in appearance and material, there is a huge choice:

- laminated MDF facade. The facade is more moisture resistant than the chipboard, more dense, basically laminated to a tree. MDF facades are of low price, quick to manufacture, film on the edges, may eventually move away and crack;

-Facades can be, as deaf, and have curly cutouts for stained glass, the glass is attached to the back of the overlay;

-softforming - looks like MDF, it has a relief on both sides and a two-color layout. This material can only be used in dry rooms;

- Postforming, based on chipboard or MDF plates. The wear-resistant plastic of the edge of which is wrapped on 90 * or 180 * degrees is applied over the plate. The plastic is very thin, so it does not create unnecessary seams on the corners. This type of facade is a quality and durable product;

- the facades of plastic - expensive and very high-quality. The basis is a chipboard or MDF plates, on both sides of the plate are faced with a thick plastic, the plastic can be both glossy and matte. This facade is always executed in the form of a flat surface of strict design, the edges are protected by ABC edge, or aluminum profile. At present, super glossy acrylic plastic has become very popular;

-woody or facade of veneer, very expensive pleasure, but finds its lover;

facades painted enamel, very beautiful facade, but has low chemical resistance, is prone to scratches and deformation;

-Aluminum façade with glass, very fashionable, beautiful, but difficult to work and install, as you need non-standard fittings for fastening.

Back walls and bottoms of boxes of cabinet furniture

Wood fiber board (dvp) is the main material for the rear walls and the bottom of the boxes, has a thickness of 3 to 5 mm.

Sheets of a wood-fiber plate, basically, are fastened on саморезы with a press washer. Under the press washer, it is necessary to drill a hole so that the sheets do not crack.

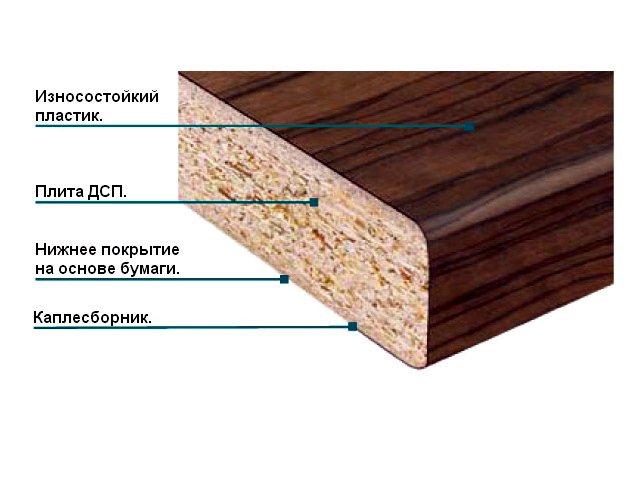

Worktops for cabinet furniture

The main countertops are made of chipboard, with mandatory processing of the edge edge of PVC 2 mm.

The thickness of the countertop can be 16 or 22 mm. But, this thickness is suitable for office and writing desks. For kitchen use countertops with a thickness of 28 -38 mm, the top side of the countertop for the kitchen, is pasted with a durable plastic postforming.

Particular attention should be paid to the edge of the saw. The edge of the saw should be smeared with silicone sealant and covered with a special aluminum profile. If the docking of several cabinets with different worktops is made, the edges are closed with a profile with a corner and connecting strip. The decorative corner closes the gap between the wall and the table top. Often the apron is trimmed with a wall panel, the wall panels are low-budget and have no seams. Worktops are attached to the tables from below, with short screws, to horizontal spacers. In addition to worktops made of chipboard, there are countertops of natural or artificial stone, but these are more expensive products. An alternative, you can make a countertop of tiles or porcelain stoneware. For this purpose, a cement-fiber sheet is attached to the table and tiles or porcelain stoneware is already glued on it.

Assembling the details of cabinet furniture

A very important point for a reliable and durable service of furniture is the correct assembly and arrangement of parts.

For example, you are assembling a walk-in closet. How will you fix the countertop? A table top, like every detail, can be made an invoice, with support on the side walls and nested, i.e. between the side walls the table top is inserted, in the second case, the pressure force will be laid out on the side fastener of the countertop against the walls, the force of the impact will tend to break and burst.

Total, which option is correct, of course the first.

And vice versa, in a hinged cabinet, if the top shelf is made a waybill, and the fixing point of the cabinet is on top, then all the bolts will break out of the tree, but if the top wall is nested, the voltage will go to break and this cabinet will last for a long time.

Furniture fasteners

In cabinet furniture, in the main, the parts are connected at right angles with the help of furniture fasteners or hardware.

In addition to the hardware, wooden dowels are used, for fixing the furniture corners in a more reliable way. Furniture corners have their popularity, but because of the cumbersome, not presentable appearance, this fastening is considered obsolete. The main anchorage is the Eurovint or Confirmat. Because of the large thread, the euro screw is kept inside the chipboard very well.

The most popular confirmations are 7x50 mm. A special drill, for the euro screw, is made a hole, it must be strictly perpendicular. Screws are twisted by means of a nozzle on a screwdriver or a 6-faceted key.

To hide the screw of the screw, they are closed with plugs. The most correct method of attachment are eccentric ties. Such fastening has holes only from the inside of the furniture. The screed must have a precise drilling, a Forstner drill is used.

Furniture fittings

The handles are attached to the screws. The legs align the furniture and separate furniture from contact with moisture. To quietly open the cabinet doors use a silicone damper. It is glued at the top or bottom of the door or on the end of the cabinet.

Furniture hinges, for them round cutouts in facades are required. Cutouts for loops are made in the furniture workshop, but usually if you use standard workpieces, cutouts in the facades are already present.

Furniture boxes and their guides

The perimeter of the furniture box is mainly collected from the chipboard, the bottom of the LDWP. If a beautiful facade of the box is required, a patch on the main frame is made, it is fixed from the inside. Boxes are usually retractable. The movement of the boxes is carried out along the guides and has two types.

The roller guides are attached to the bottom of the box and have a big minus, since such guides do not allow the drawer to extend fully.

But the ball guides (telescopic) have full extension and smooth running. In addition, Blum has metaboxes and tandemboxes.

Doors for cabinet cases

Sliding doors are the main element of the closet.

For such doors it is necessary to buy high-quality hardware, from domestic ones one can advise the Aristo system. Doors should not be wider than one meter. To prevent injury, install a mirror in which there is a film from the wrong side.