Pools have already ceased to be a luxury item, accessible only to rich people, now this pleasure has become available to virtually every owner of their own site. In this article, we'll talk about pools of polypropylene - an excellent alternative to classical stationary pools. What is a pool of polypropylene, how is it assembled, what are the advantages of polypropylene pools in front of conventional stationary pools, is it possible to mount such a pool independently and how to do it? All of these issues will be considered below.

Content

What is a polypropylene pool, its advantages

This type of pool is a container welded from polypropylene sheets by the method of polyfusion welding. Ready capacity is installed in a specially prepared pit with a concrete cushion, or simply on a clean and level surface.

A pool of polypropylene is really a worthy alternative to a stationary pool, which has a whole host of advantages, primarily related to the properties of polypropylene.

This material is simple enough to process, which makes it possible to give the basin of the pool the most intricate shapes that perfectly fit into the interior of the premises or the infield.

With the help of polyfusion welding it is possible to make completely sealed bowls, which eliminates the need for additional waterproofing. All additional elements - nozzles, lamps, hydro-massage devices are mounted directly in polypropylene, thus saving on additional insulation.

The internal surface of the pools does not need to be trimmed, the tank is simply installed in a prepared pit, filled with water, and the pool is fully ready for operation.

A pool of polypropylene can also be installed on the surface of the ground, you only need to align and clear the debris area under the pool.

Polypropylene is an environmentally friendly material, completely harmless to humans, it does not become slippery in water, which greatly reduces the likelihood of injury.

The great advantage of polypropylene basins is their ease of operation and maintenance. On the surface of polypropylene does not multiply fungus and mold, which allows you not to use harmful chemical cleaners. The pool is cleaned with a trimmer with a special brush-attachment.

Polypropylene perfectly withstands high temperature changes - from -70 to +300 degrees Celsius. In addition, this material has good thermal insulation characteristics, which eliminates the need to constantly heat water and make additional insulation.

The polypropylene bowl is resistant to aggressive environment, it does not lose color, shape and tightness for several decades.

Installation of the pool of polypropylene

site selection, foundation pit preparation

The production of polypropylene basins is a rather lengthy and time-consuming process. The first thing to do is to choose the right place for the future pool. Very good, if the excavation will be in clayey soil. Next to the future reservoir, trees and high bushes should not grow, as leaves and branches will fall into the water. The pool is best done on a small hill, where there is no ground water close to the surface. After the place is chosen, you can proceed to dig the excavation.

First we make the markup.

Here it is necessary to take into account that the size of the pit should be more than a cup approximately one meter in width and length. We excavate the excavation by hand or with the use of construction equipment. The depth of the pit should exceed the height of the pool bowl by at least one meter.

When the pit is excavated, its bottom should be carefully leveled and compacted, then pour a small layer of small gravel.

After this, you need to make a reinforcement mesh made of reinforcement with a cross section of 30 mm. Further, the bottom of the foundation pit is poured with a layer of concrete not less than 30 cm thick, it is necessary to strictly follow the horizontal, otherwise, when the pool is filled with water, all unevenness will be emphasized. After the concrete has solidified, we put a layer of geotextile on top and a heat insulator on top of it. As an insulator, extruded polystyrene foam can be used. Sheets of insulator must be secured with adhesive tape or paper clips.

If it is planned to make a pool for a dacha made of polypropylene, then it is more expedient to do without a trench, but simply to install a bowl on a flat and clean surface. For the winter, the water from the bowl can be completely drained, and turn the bowl itself upside down or, if dimensions allow, be taken to the room.

installation of bowl made of polypropylene

If the bowl is large, it is collected directly in the foundation pit. Small bowls are mounted separately and installed in the pit in the finished form. When the bowl is ready and installed, all additional equipment is installed: luminaires, nozzles, filters, hydro massage systems, etc. All pipes are taken to a room intended for pool maintenance.

Then the bowl must be secured. To begin with, spacers are installed inside the container, ensuring the stability of the entire structure. All pipes are cleaned in special protective sleeves, after which a formwork is installed along the perimeter of the bowl, inside which the mesh is made of reinforcement.

The basin should be filled with water approximately 30-40 cm, then a concrete solution is poured into the formwork, the level of which must coincide with the water level in the pool. After the solution is frozen, another 30-40 cm of water is poured into the pool and concrete is poured on this same height. So, gradually the concrete is poured into the side walls of the excavation to the required level. When the concrete is completely frozen, the shuttering is removed, and it is possible to start cultivating the territory near the pool - putting tiles, sowing a lawn or a flower bed, installing benches, lighting devices, etc.

Pool of polypropylene own hands

If there is a great desire and some skills in construction, a pool of polypropylene can be done on their own. To do this, you will need the following tools and building materials:

Sheet polypropylene for swimming pools. The size of the sheet is 4x1.5 meters. The thickness is 8 millimeters. The sheet can be thinner or thicker - it all depends on the size of the pool. Buy polypropylene sheet can already be in the form of ready-board systems for artificial reservoirs directly from the manufacturers. You will also need a soldering iron for polypropylene with several nozzles, a polypropylene rod for seams, and a saw or electric jigsaw. By the way, the tool for working with polypropylene is not cheap, so it is more expedient to take it for rent.

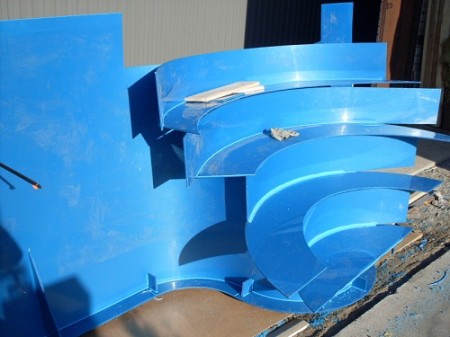

installation of a bowl for pools of polypropylene

The work begins with the drawing up of a detailed drawing of the future basin taking into account all parameters: height, radius, width and volume. In the drawing, you also need to schematically indicate the steps. Steps in the pool of polypropylene is best done not hinged, but stationary - they are more safe, convenient, and look much more attractive.

Further all the works are performed according to the following algorithm:

We prepare the bottom of the reservoir: weld the sheets of polypropylene and lay it on the bottom. On the basis draw a contour bowl.

We cut out the canvas and weld it strictly along the drawn contour from the outside.

Inside the bowl, we set the spacers and vertically expose the walls of the bowl with respect to the bottom.

Preparing the steps. All joints from the inner sides of each step are welded using a rod made of polypropylene. The outer side of the steps should be welded using a joint nozzle, which has an angle of 90 degrees. After a step as the steps are ready, they can only be welded to the bowl. After mounting the ladder, the stiffeners are welded to the bowl, in steps of approximately 60 centimeters.

In this work on the installation of bowls made of polypropylene can be considered finished. Further actions we described above - pouring the walls of the excavation with concrete, the layout of communications, ennobling the territory, etc.

The cost of a pool of polypropylene depends on the size and shape of the bowl. For example, the pool is 3 meters wide, 2 meters long and 48 cubic meters in depth, with a 24-square-meter water area. m., will cost you from 120 000 to 170 000 rubles, depending on the shape of the bowl.

Retail cost of a sheet of polypropylene in the size 4х1.5 meters in thickness of 8 mm makes approximately 7200 rubles. As you can see, you will not be able to save enough to build a pool on your own, if at all. The fact is that welding with an extruder using a polypropylene rod is not considered the most reliable and durable. Especially if it is not done by a professional. With this method of welding, it is very difficult to achieve uniform heating of the sheet, which in the future can entail repair of the pool of polypropylene. You can eliminate leakage in the pool, of course, and with your own resources with the help of improvised means, but it is better to entrust the assembly and troubleshooting in the pool to specialists.

Maintenance and care of the pool of polypropylene

conservation of the pool for the winter

Includes:

- Washing sand in the filter.

- Lowering the water level to the nozzles.

- Dismantling of lighting devices.

- Draining of water from the heater, pump and filter.

- Installation in water compensators (plastic bottles, cans, foam).

- Use a winter tent as a cover.

- Dismantling the electric heater, pump and filter head.

care for a pool of polypropylene in the summer

As we noted above, polypropylene basins do not require careful care, since polypropylene is resistant to ultraviolet and temperature changes. In the cold season, you can not completely drain the water from the pool, but just to conserve it according to the instructions. If we install a filtration and purification system, the water can not be changed for several years. To prevent the emergence and growth of algae, to maintain the desired level of Ph can be with the help of special drugs that also help remove limescale on the bottom of the tank.

Cleaning the pool also does not take a lot of time. The bottom and walls are cleaned with a special brush with a long handle, which is connected to the skimmer.

Use a pool of polypropylene and can be in cool weather. To do this, you need to install an electric heater for water.

In addition, over the pool it will be advisable to install a transparent pavilion - this will allow to operate the pool of polypropylene almost all year round.

https://www.youtube.com/watch?v=TpEWkBGaCmk