Every year, human life becomes more comfortable. The first mention of the aqueduct dates from the Xth century BC. and today we do not even imagine how it is possible without this invention. If in municipal buildings the utility services are responsible for the normal operation of the water supply system, then in private houses and in suburban areas this falls entirely on the shoulders of their owners.

Content

- 1 How water freezes in pipes

- 2 How to heat a plastic pipe

- 2.1 heating the pipes from outside with hot water

- 2.2 heating the pipes from the inside with hot water

- 2.3 heating the pipes from the inside with steam

- 2.4 heating of the pipe with hot air by a building or household fan, heat fan

- 2.5 heating the pipe with a heating wire

- 2.6 removal of ice cork with hot salt solution

- 2.7 pipe heating by electrolysis

- 3 How to reheat a metal pipe

- 4 What if the water in the pipe is frozen in the ground?

- 5 So that the water does not freeze in winter

- 6 Helpful Tips

How water freezes in pipes

If we have to deal with the problem of freezing water in pipes, then most often it happens with pipelines of water supply, sewerage and heating systems. When placing pipes within reach, it is relatively easy to perform defrosting operations. It is more difficult when pipes are frozen in the ground or, for example, in a wall where access is absent.

It is well known that under normal conditions and temperatures below 0 ° C, water changes its aggregate state and passes from liquid to solid state, its volume increases significantly, which can lead to rupture of the container in which it is located.

Water in pipes can freeze for the following reasons:

- insufficient thermal insulation of pipes;

- laying pipes in the ground at shallow depth;

- reduction or cessation of water circulation in pipes;

- the drop in the ambient temperature is below the calculated one;

- violation of power supply for devices for electric heating of pipes;

- untimely drain of water from the system.

To determine the place of freezing of water it is enough to touch the cold sections of pipes.

How to heat a plastic pipe

Due to their high elasticity, plastic pipes are less susceptible to ruptures in the event of water freezing in them, however, due to the low heat transfer coefficient of the plastic used, the process of defrosting them is more labor-intensive than metal ones and takes much longer.

For the manufacture of plastic pipes, plastics are used, which are dielectrics and do not conduct electric current, so for their defrosting it is impossible to use such a simple and effective method as heating with high currents. And their low fire resistance does not allow using another common method - heating with the help of an open flame source.

heating the pipes from outside with hot water

For defrosting, it is necessary to wrap the frozen area with rags so that the hot water absorbed in them can give away more heat. Bottom place a container, which will drain the used water or simply spread the rags.

Hot water should periodically water the frozen section of the pipe. If there is not enough water, then the collected liquid should be reused, heated in any convenient way.

If the pipe is horizontal and there is free space around it, it is possible to bring a chute from below to place the pipe and pour hot water, only it will be necessary to seal the chute on both sides so that hot water does not flow. As the water cools, the water changes to hot water.

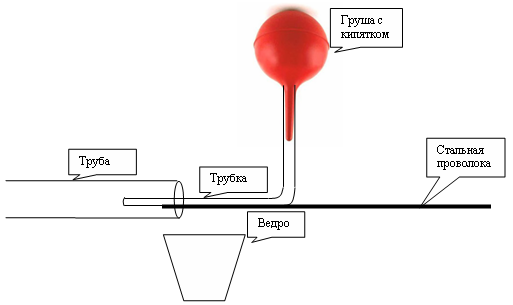

heating the pipes from the inside with hot water

Due to the low thermal conductivity of the plastic, a greater effect can be achieved if the pipe is heated from the inside. However, if you pour hot water into the pipe, there will be no circulation of water near the ice stopper. To ensure a constant flow of hot water to the place of freezing, it is necessary to remove from the pipe a faucet or another element of the water lock and insert a flexible hose into the pipe. The length of the hose should be sufficient to reach the end of the ice plug, and it should not soften under the influence of high temperature. If the defrost pipe is straight and has a sufficient diameter, the hose can be replaced with a smaller diameter plastic tubing.

When hot water arrives directly to the place of freezing, the heating of the pipes will take place quite quickly, it is only necessary that it be fed continuously. As the ice melts, the hose or tube is pushed further into the pipe until the plug is removed.

Hot water can be supplied by gravity from a large capacity vessel, from a hot water supply system or by a pump for pumping liquids. It should be noted that the supplied water and melted ice will flow out of the pipe, so it is necessary to provide a capacity in advance, where it will merge.

In the case where the pipe to be thawed has sharp bends, then you can use a thin steel wire, to the end of which you must securely attach a thin flexible hose. The wire together with the hose with hot water is introduced into the heated pipe and thanks to its flexibility it allows you to overcome steep turns.

After defrosting, it is recommended to leave the tap for some time to completely remove the ice remains and raise the temperature of the pipe passing over it with water.

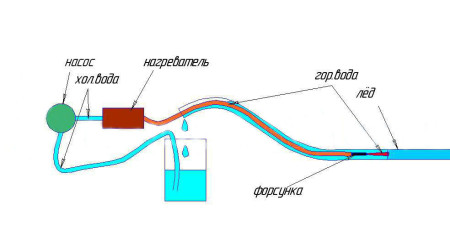

heating the pipes from the inside with steam

This method is similar to heating the pipe with hot water from the inside, with the difference that the water vapor received from the steam generator is used as the heat carrier. The latter is an airtight container with water, above which the nozzle for securing steam is attached. To produce steam, you can easily adapt an ordinary pan-pressure cooker. The water is heated to a boil on a gas stove, a fire, using a blowtorch or a gas burner. One end of the heat-resistant hose is put on the steam generator connector, the other end is inserted inside the pipe and the steam is fed to the place of freezing. As thawing, the hose is pushed further into the pipe.

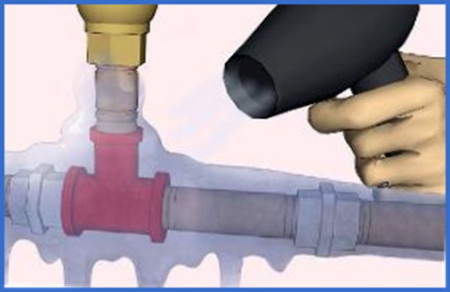

heating of the pipe with hot air by a building or household fan, heat fan

Melt the ice in a plastic pipe that is within reach, you can use hot air from a building or household hair dryer, an electric heater. However, it should be borne in mind that plastic pipes are not designed for high temperature and can be deformed or even melt when overheating, so the building hair dryer should be kept away from the surface of the pipe.

To warm the pipe, it is necessary to evenly heat the desired area until completely thawed. However, if its length is significant, in order to reduce the heat loss and accelerate the defrosting process, it is recommended around the heated section to create an air duct with the help of cardboard, thin sheet metal, heat-resistant plastic, etc., in which to supply hot air.

Often, because of frozen ferroconcrete or brick walls, the water freezes the pipe in the place of their entry into the building. For defrosting, it will be sufficient to warm the wall well, and to reduce heat losses, the heated space should be temporarily closed with some screen from improvised means.

heating the pipe with a heating wire

For defrosting, you can use special heating wires designed to protect the pipe from freezing. There are different types of data wires, differing from each other in capacity, design, material of manufacture, location and type of installation on the pipes. To increase the thermal conductivity, the heated section of the pipe must be wrapped with aluminum foil, over which the helix is wound with a heating wire and a temperature sensor attached to the pipe.

To reduce heat loss, it is desirable to equip a pipe with a wire with thermal insulation. The wire serves as a heating element, the thermal sensor monitors the temperature of the pipe to prevent its overheating and deformation, and the thermostat, to which the wires and the sensor are connected, supplies power for heating. Thawing of ice inside a plastic pipe with the help of heating wires can last up to 3 hours.

removal of ice cork with hot salt solution

If you add salt to the ice, it will melt at a temperature below 0 ° C. You can use this property to defrost the pipes by pouring in them a hot saturated salt solution in water. One has only to be prepared for the fact that the process of removing ice will be longer than in other described ways, as the water will gradually cool down.

pipe heating by electrolysis

ATTENTION! This method uses a voltage of 220V, which is life-threatening, so it should not be used by those who do not have sufficient knowledge of electrical engineering!

To make the defrosting process safer, it is advisable to supply power through a powerful power isolating transformer.

The water we use in everyday life contains a small amount of dissolved salts and is a weak electrolyte. When the voltage is applied to the electrodes immersed in water, a reaction occurs with the release of heat, which can be used to melt the ice in the pipe. For this purpose, a two-wire wire is used, for example, of GDP-2 type, rigid enough that it does not bend in the pipe.

It is necessary to split the veins with a knife, one of them to be shortened and to remove the insulation by several centimeters from both veins. The stripped wires must be wound around the wire in such a way that they are not far apart, but do not touch, otherwise a short circuit will occur. The end of the wire with stripped wires should be inserted into the tube and pushed until it engages in an ice cork. On the opposite end of the wire, apply a voltage of 220 volts, preferably through a separation transformer. As the ice melts, it is necessary to push the wire further into the pipe.

How to reheat a metal pipe

Since the metal from which the pipes are made, has a high thermal and electrical conductivity, resistance to high temperatures, metal pipes can be heated easier and faster than plastic pipes. You can do this in the following ways:

heating of the pipe with the open flame of the blowtorch, gas torch, torch

In order to reduce heat losses and protect surrounding objects from fire, it is advisable to protect the heated area with non-combustible materials, for which you can use a metal sheet, a piece of asbestos cement pipe, asbestos cloth, etc. The frozen section of the pipe must be warmed evenly with an open flame.

When working, the metal sheet will heat up, so periodically it is necessary to cool it with water or snow.

electric heating of the pipe

For defrosting ice in metal pipes, it is possible to use the property of conductors to heat up when an electric current flows through it, and the stronger the current, the more intense the heating of the conductor. In case of freezing of water to the ends of the area that needs to be heated, connect the low-voltage wires of the electric welding machine.

Given the variety of options for the design of welding machines, the different diameters and lengths of the pipes of the heated sections, the current and the operating time / pause of the welding machine will have to be determined experimentally, but it is necessary to start with small welding currents, including the apparatus for about 30 seconds and pauses for 10 seconds. do not warm up, then increase the operating current.

At the same time, this method will be ineffective in defrosting large diameter pipes or a considerable length of the heated section, since the current strength will be insufficient for heating up massive metal structures.

In addition, all methods applicable to plastic pipes can be used for heating metal pipes, in addition to heating by means of electrolysis.

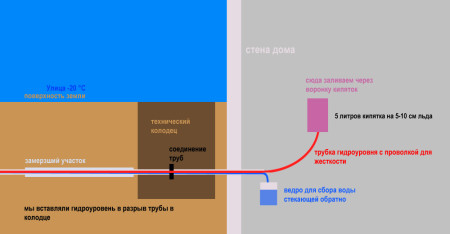

What if the water in the pipe is frozen in the ground?

The most difficult is the case when the water in the pipe is frozen in the ground. Because of the lack of direct access to the water pipe, it is difficult to determine the location and dimensions of the ice cork, as well as the possible nature of the damage. If a metal pipe is used as the pipeline and it is possible to connect the electrodes to opposite sides of the frozen area, it can be heated by an electric current using a welding machine. If one side is unavailable, the length of the section is too large or a plastic pipe is used, then it is possible to unfreeze the pipe with hot water or steam from the inside. These heating methods have been described in more detail above.

It is possible that work may be required to excavate the pipe to eliminate the ice jam and eliminate a possible gap. Due to the high density of frozen soil, excavation in the winter is very laborious, so first of all it is necessary to try to still unfreeze the pipe laid in the ground without digging a trench.

The pipe can be heated in an open trench in any way suitable for the specific material from which the pipe is made. When heating the water pipe with a hair dryer or fan heater, remove the insulation from the pipe, cover the frozen area with cardboard, film or other materials, thereby creating a closed volume around the pipeline where hot air should be supplied.

So that the water does not freeze in winter

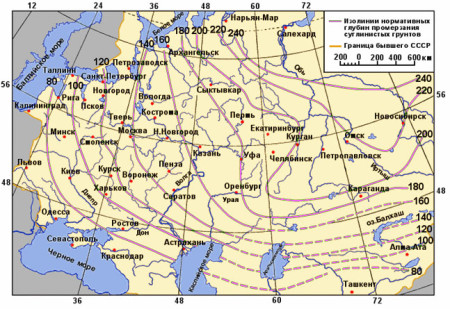

In order for the water not to freeze in the pipes in the ground, they must be buried below the depth of freezing. For different regions of the country these indications vary significantly and range from 80 to 240 cm, so before laying the pipeline it is necessary to carefully study the map of the depths of soil freezing.

Pipes with water must necessarily be equipped with thermal insulation, but it must be understood that it only preserves heat, and does not heat pipes with water, so it is impossible to exclude freezing when water circulation decreases or stops.

For thermal insulation, glass wool, seals of various types from expanded polystyrene, basalt, foamed polyethylene can be used.

That water in pipes did not freeze it is expedient to use heating wires. A wire with a temperature sensor is attached to the protected pipe and connected to a thermostat that controls the power supply. To reduce heat losses and reduce power consumption, pipes with heating cables must have reliable thermal insulation. This method is guaranteed to protect the pipes from freezing, but entails the complication and cost of construction, as well as additional costs for electricity.

If the water in the pipes periodically freezes when the circulation ceases, for example, at night, when there is no water flow, it is advisable to leave the water turned on for this time. The greater the pressure of water, the less likely that the pipes will freeze. This method can not be recommended for permanent use, since water consumption is significantly increased.

When equipping the water pipe, if possible, use pipes with a larger diameter, so they have a thicker wall and the pipes themselves have a larger volume of liquid, which means that they are subject to less freezing.

Reinforced concrete and metal have a higher thermal conductivity than the ground, so do not place the pipes next to buried metal or reinforced concrete structures, since the possibility of freezing the ground increases on their side. If they can not be spread over a considerable distance, it is recommended to carry out additional insulation by placing sheets of heat-insulating material between these structures and the pipeline. The same rule applies when laying a water pipe through the outer walls of buildings, so it is necessary to perform the insulation of pipes and to exclude direct contact with the walls.

Helpful Tips

- it is necessary to take measures as soon as possible to defrost the ice in the pipes in order to prevent their rupture;

- before carrying out work on heating the frozen area, it is necessary to cut off the water supply to the pipe;

- if it is not possible to shut off the water supply to the pipe, it is necessary to be prepared for the fact that after the ice plug is eliminated, the water will again come under pressure into the pipe;

- the defrosting of sewer pipes from the outside should start from the bottom, so that the melted water drains into the sewer system;

- after defrosting the pipe, it is recommended to insulate the area to avoid re-freezing;

- when working with an open fire, fire safety rules must be observed;

- the temperature of the water that the pipes warm up should be as high as possible;

- in case of using water only during the warm season, it is necessary to drain the liquid from the pipes before the onset of cold weather and blow the system to remove the water residues.