The "Gold Collection" of a Home Master must have drills, or even better, a set of drills. Due to the purpose and efficiency of this cutting tool, you can perform many operations for metal, wood and plastic. It remains only to prepare for work a hand drill, and send its feet to a specialized store. Who is with us?

Content

Cutting tool number one

A special cutting tool, which is universally used for making different in diameter holes in a continuous metal layer, are drills.

The modern market of cutting tools is saturated with various drills for metal. However, according to experts, it is difficult to acquire a real high-quality tool. What are the criteria for choosing a drill? To appreciate all the positive qualities of this elegant cutting tool must be learned:

• its design features

• fabrication material

• marking on the drill

• the color of the drill bit.

A set of positive qualities inherent in the cutting tool number one, will make it clear that the choice is made correctly. We begin with the design features.

Drill for metal

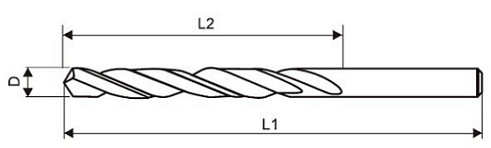

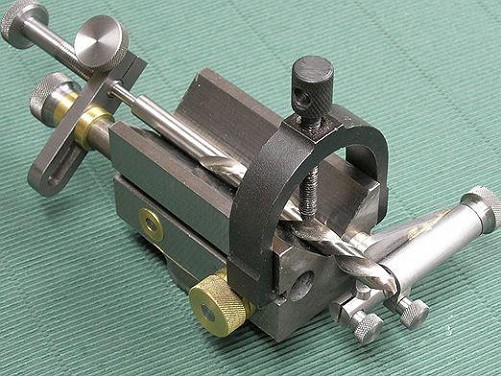

Drill for metal and not only constructively consists of the following parts:

• Cutting part

• Working part

• Shank.

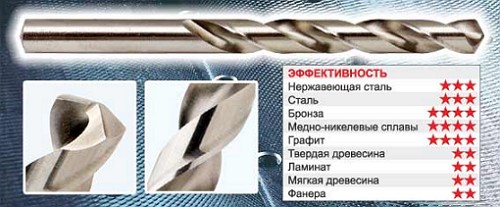

The main purpose of the drill is to create holes on the surface of the metal, so metal drills should ideally be suitable for all types of metal - existing types of steel and cast iron, as well as non-ferrous metals.

The cutting part of the drill for metal has cutting edges, due to which the chip shakes are carried out. The working part ensures the direction of the drill during the cutting, while reducing the friction of the side surface.

Shank (medium, short and long series) is designed to secure the drill in the working tool securely.

Advice from a specialist

Experienced specialists and masters advise to purchase drills from a well-known manufacturer. The answer is obvious: the manufacture of drills from the manufacturer is carried out exclusively from high-quality steel, and in the production process use solid-rolled billets. Preforms made of high-quality steel are characterized by increased resistance to stresses and kinks. It is possible to distinguish a drill from a single billet by weight. This drill has an impressive weight, compared with welded or brazed blanks of cheap materials.

What does the marking mean?

The business card of any drill is its marking on the outside. Therefore, when considering a drill in a specialized store, pay attention to what will be written on the drill. Marking is applied in a factory way in the form of a clear engraving. The marking of the drill starts with a letter that carries information about the material of manufacture.

So, for example, "P" will mean that this is a high-speed tool steel. Drills are made of high-speed steel grades P9, P12, P18, P9K5. The marking in the form of a numerical value will show the composition of the alloy material from which the drill is made. For example, K6 is cobalt, M3 is molybdenum. When planning to purchase a domestic manufacturer's drill, note that the marking will be applied depending on the diameter of the drill bit.

Advice from a specialist

If there is no marking on the drill, this does not mean that the drill is "left" or defective. Drills up to 2 mm in diameter are not labeled, because it is almost impossible to read microscopic markings on such a thin drill with the naked eye. On drills of larger sizes, the diameter of the drill bits for metal is indicated, and the grade of steel, as well as the accuracy class. Drills from a foreign manufacturer are labeled as HSS values. Foreign manufacturers do not mark the hss bit for metal, the necessary information is applied directly to the product packaging.

Difference drill in color

The processing of the drill in industrial conditions is reflected in its chromaticity. A black drill indicates that the finishing was completed and the drill bit has an increased wear resistance. If the color of the drill is gray, this will mean that no additional processing to improve the strength properties has been carried out. Quality drills from the manufacturer have a golden hue, which signals the application of an additional layer. The additional layer imparts strength to the drills on metal and reduces friction when passing the tool.

What types of drills are preferable to work with metal

The most popular metal drills are the following types:

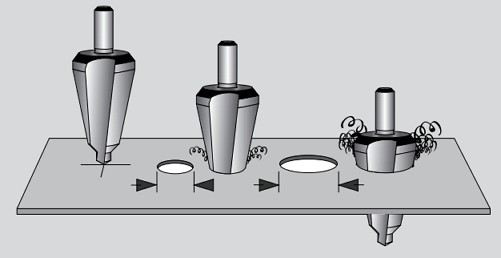

• Cone

• stepped

• Crowned.

cone drills

Cone drills are used for drilling holes of large diameters.

A cone drill for metal can be used for thin-sheet materials, steel pipes and profiles, for drilling existing holes in steel billets up to 5.0 mm thick. The specific conical shape provides the tool with an easy exit from the material, and the deep groove provides a high cutting ability.

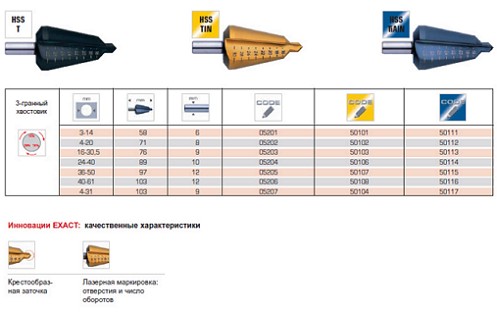

cone stepped

A distinctive feature of the stepped drill for metal is the characteristic construction of the working part. The drill diameter drifts at an angle of 45 degrees. What are the advantages of a stepped metal drill in comparison with traditional cone drills? Of course, this is an excellent opportunity to drill holes of different diameters with one tool.

Manufacturers have taken care of the unique qualities of the step drill: strong cutting edges, quick chip removal, resistance to overheating and a significant working life. Qualitative step drills can replace even entire sets of cutting tools. In addition, it is possible to use a drill for a hand drill.

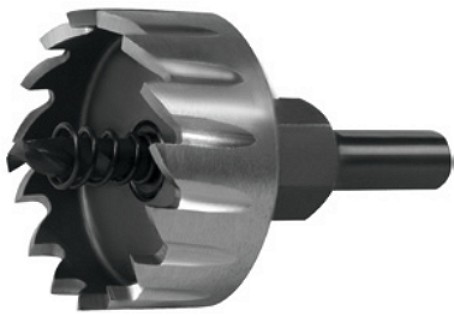

core bits

Crown drills for metal are used when working with drills and drilling machines. Due to the presence of a powerful cutting part, drills are used for working with steel, casting and non-ferrous metals, as well as plastics. When working with a core drill, high accuracy of rotation is ensured due to a shallow passage.

In the case of a reduction in drilling quality, it is possible to manually sharpen the drill for metal. The advantage of using crown drills during work is to obtain a hole with a flat edge, without defects and scoring.

Advice from a specialist

Of course, that drills in the home workshop are different. Therefore, the optimal option can be considered the acquisition of a set of drills. Help you to choose a drill for metal video will help.

Choose skillfully!