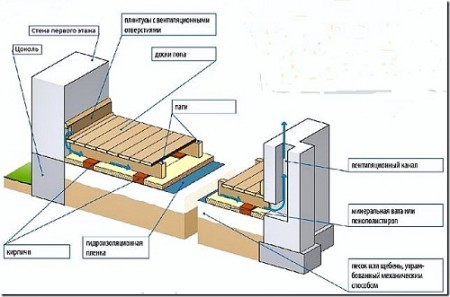

Very often, the floor in a private house has a rigid fixing in the walls, but it is preferable to make a floating floor, that is, a floor having its own independent foundation, which is made of columns or small walls. This is done in order to arrange ventilation space under the floor.

Content

Why do you need floor ventilation?

Ventilation for wooden floors is necessary for one simple reason: a tree without proper ventilation begins to gradually block and rot, that is, to collapse. And the basis, the so-called rough floor, on which the heater will later be laid, is made of wood. The gradual destruction of the tree will inevitably lead to the fact that one day the floor will simply fail. I'll have to disassemble the entire structure, and mount it again, this time complying with all the rules.

But there is a danger much greater than the collapse of the floor construction. These are fungi and mold, which can reproduce in clandestine dampness. Disputes of fungi ways to cause catastrophic damage to the health of people living in the house, provoking the appearance of serious diseases. And if the house is experiencing increased dampness, when heating is turned off, this is a pretty serious reason for concern. So the ventilation of the wooden floor is a necessary thing.

Ventilation options for floor

There are two ways of ventilation for wooden floors: natural ventilation and forced ventilation. With natural ventilation, air circulates freely in the space below the floor.

This is achieved by a device of so-called blowouts, which are ventilation holes in the foundation. This does not arrange any hoods and additional devices for ventilation. This method is very popular, despite significant heat losses in the winter. To reduce the heat loss, winter blowouts are usually tightly closed with cork of wood or clay.

As for forced ventilation under the floor, it is a device for inflow and exhaust of air.

Got quite widespread, but has a number of shortcomings. For example, a strong noise, which can only be got rid of by special silencers. Which, incidentally, also need to buy. And such silencers often cost more than the ventilation in a private house. However, if there is no shortage of funds, then this type of ventilation will serve faithfully for many years.

Holes for ventilation in the foundation

Air or ventilation holes are best done during the construction phase of the house. For the device of blowouts in the base, scraps of metal pipes or special shapes that are bought in stores are used. The airs are arranged at a height of about 50 centimeters from the ground, if the height of the base allows. This height is dictated by the height, which reaches the snow cover in winter. After all, if the snow closes the air, they will, naturally, not work. But the main danger is the ingress of thawed water into the underground through the air.

The size of the vent in diameter should be about 10-11 centimeters. The air should be placed on the wall every 2-3 meters. Trying to save and place only one vent hole on the wall is not recommended, as these holes are not enough for good ventilation. The outermost product must be located at a distance of at least a meter from the corner of the foundation. This is done in order to maximally ventilate all the space in the basement.

How do you ventilate the floors in a house that is already built?

It will take a minimum amount of materials. This is, first of all, pipes for the installation of air ducts, deflectors and pipe clamps. If the holes in the foundation were not made in advance, they will have to punch them. But the game, as they say, is worth the candle.

The exhaust and supply pipes should be located at different ends of the basement. The hood is placed in such a way that it, passing from the ceiling of the basement, is taken out over the roof about half a meter. One end of the supply pipe should be located about half a meter from the floor, and the second - 50 centimeters from the ground.

The diameter of the pipes can be arbitrary, but usually for such purposes use pipes with a diameter of 12 centimeters. Such a size will ensure the necessary airflow to the basement.

Very often, windmills are closed for the winter to avoid heat loss. But you can not do this. In winter, due to the significant height of the snow cover, there is a constant thawing of snow. Because of this, the basement significantly increases the level of dampness, which can lead to molding and rotting of the bearing beams. To prevent this, constant ventilation is necessary. In the case where the ventilation hole is closed, dampness starts to accumulate in the basement, creating an excellent environment for the reproduction of fungi and the spread of rot.

It is for this reason that it is impossible to close down the winter air, and to ensure that the floor is not cold, you need to install a good thermal insulation. The reason for the large heat loss is that the thermal insulation layer is too thin, its thickness should be at least 2 centimeters.

Check how much heat insulation is reliable very simply - at room temperature of 22 degrees, on the floor the temperature should be at least 16 degrees. The difference should not exceed 7 degrees. If it is larger, then it is necessary to establish a qualitative thermal insulation, but not to close the air.