Mankind tends towards inexpensive affordable building materials. Probably, therefore, polycarbonate has safely taken root in country suburban areas. And grow, like mushrooms after a warm rain, greenhouses and polycarbonate arbours. The time of the first canopy appearance from this material can not be specified. It is rumored that this was done by hand.

Content

The most successful proposal to protect the site from the scorching rays of the sun, wind and rain is a polycarbonate canopy, optimal for the technical parameters of the material and installation. But, if you think that it is not difficult to build a shed to the house, then you are deeply mistaken. You will have to develop a small project or use ready-made drawings of the canopy and, most importantly, learn how to install polycarbonate sheets.

How to choose polycarbonate for a canopy

It is noted that a practical solution to create a protective structure is a canopy. Under the protection of the economic or decorative canopy to the house of polycarbonate, you can store materials and things, arrange a recreation area and arrange for temporary parking of cars.

Design and place the canopy can be in the form of a separate structure, ennobling the adjacent territory, or in the form of an adjacent building.

Hinged structures come in different shapes and types. The only thing that unites them is the erection of a metal skeleton for the canopy and the economical use of polycarbonate sheets from the manufacturer.

If you intend to create a shelter to the house, it will not hurt to find out more, polycarbonate, what kind of material and its use in creating structures.

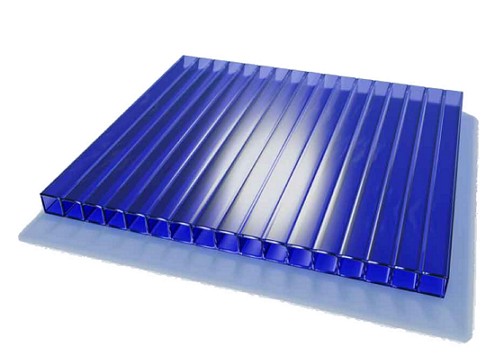

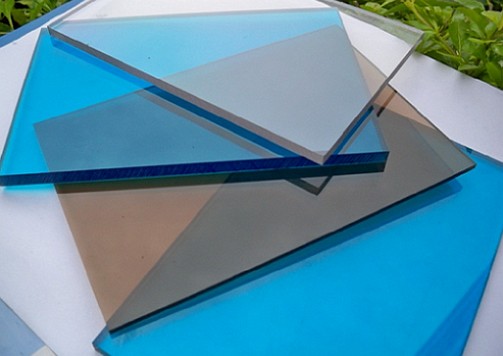

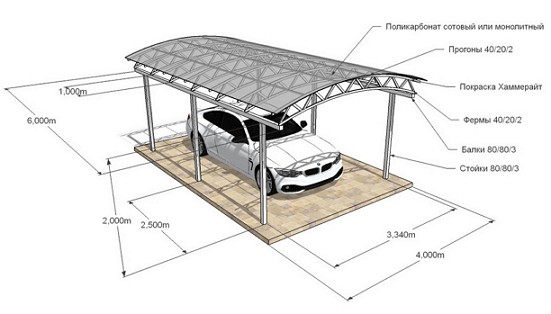

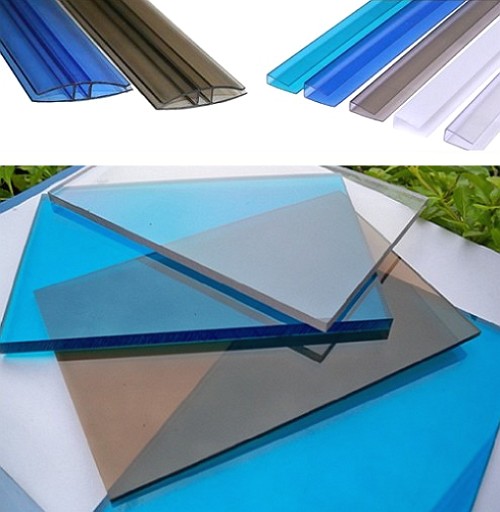

Polycarbonate sheet from the manufacturer is a honeycomb or monolithic transparent covering material with dimensions of 6 or 12 m, a width of 2.1 m. The low weight of one sheet of polycarbonate and the standard dimensions allow the material to be used when installing canopies with minimal waste. Naturally, it will be necessary to make a preliminary calculation of the polycarbonate canopy.

Helpful Tips

We will suggest that it is recommended to use sheets of appropriate thickness to create various hinged structures, determining which polycarbonate for a canopy is preferable to choose. For an arched canopy over a polycarbonate porch, preference is given to a sheet with a thickness of 60 mm, for a small arched canopy adjacent to the house, a sheet of 80 mm thick is used, for a large area of the inclined shape with the use of truss frames it is better to use sheets 100 mm thick.

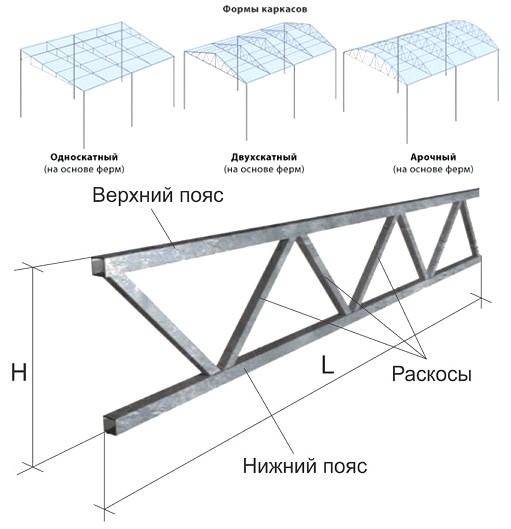

In practice, for the design of a canopy, calculations of the shape of the frame based on beams and trusses are used and applied.

Calculating the hinged frame to the house

choose the skeleton diagram

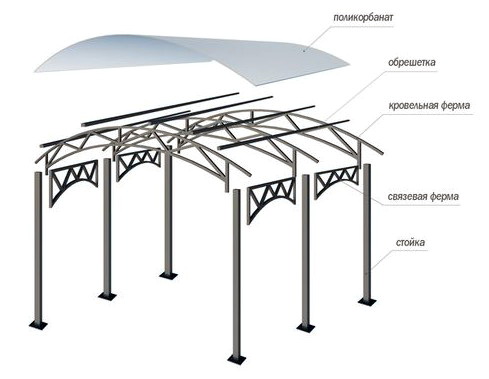

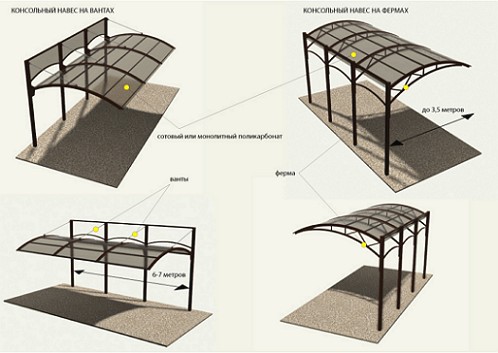

To calculate the canopy design, a beam or farm scheme is pre-selected. The calculation schemes are fundamentally different in the outline of the outline of the canopy, the dimensions, weight, and functions of the elements.

Recall that the main parameters of the frame structure of the canopy are:

• the number of pillars (pillars)

• number of beams and trusses

• number of runs

• Linked elements

• nodes of support fastenings and interfaces.

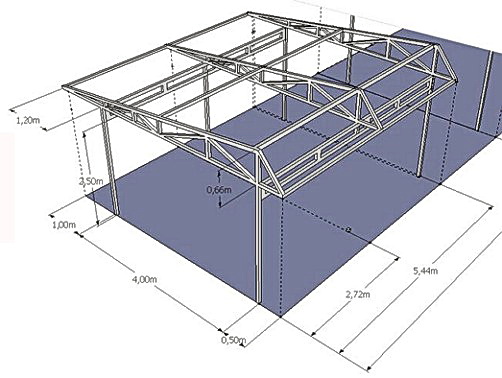

The simplest scheme of the hinged frame is a rectangular one-pitch canopy with an inclined plane on the basis of trusses, distinguished by the configuration of the belts and the type of lattice. As a canopy adjacent to the house as an extension, the upper part of the inclined plane is attached to the wall, the lower one is placed and reinforced on the pillars of the supports.

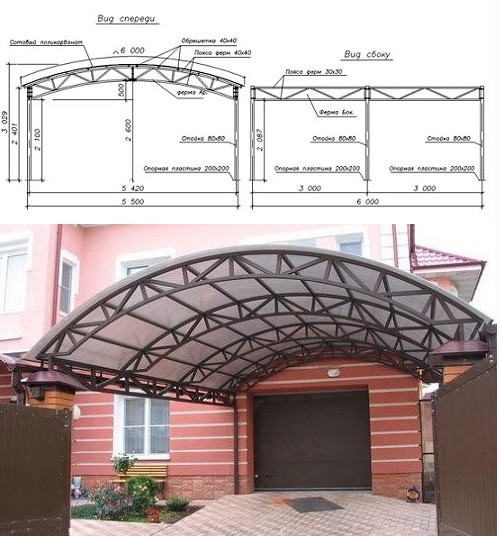

Rectangular curtain structures are most preferable when creating a polycarbonate shed for machines.

Helpful Tips

When constructing a canopy with one side to the house, it is recommended to take into account the slope of the structure, which is the basis for choosing the shape of the farm. For a canopy with an angle of inclination from 6 to 15 °, the shape of the trapeze farm should be chosen. Create trusses from the profile pipe under the hinged structure can be independently. But it is preferable to use ready-made welded roofing and bonded farms from the manufacturer and proceed with the creation of a shed frame on the basis of trusses.

framework based on trusses

To calculate a rectangular canopy, the following information is required:

• SNiP 2.01.07-85 (impacts and loads), SNiP P-23-81 (data on steel structures)

• Drawing with overall dimensions and number of racks

• tabular values of the lathing parameters

• Farm height and number of belt panels

• dimensions of span and run

• type of anchorage.

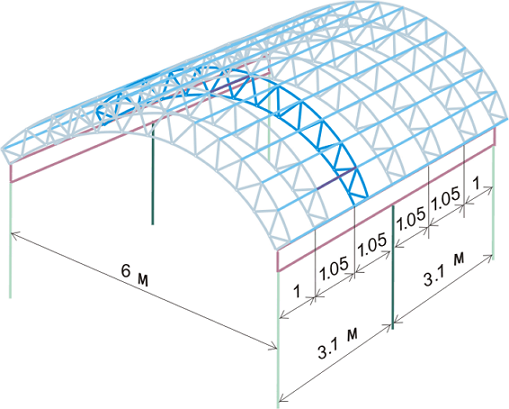

Traditionally, steel frame pipes 50х50 mm, 80х80 mm for structures up to 6-7 m in size are used for vertical racks of a skeleton under a canopy and trusses. For canopies of large size 100х100 mm and 150х150 mm.

Helpful Tips

We will not hide it to calculate a truss from a profile pipe (this is the best option for a hinged structure), it will be necessary to dig into the normative documents.

We will show that the pitch of the trusses should take into account the distance between the pipes of 1.7 m, taking into account the optimal height in the middle of the span.

For example, for a skeleton with span of a truss of 4.8 m and h of a truss of 0.4 m, with an amount of panels of the upper belt 7, the design resistance of steel structures is Ry = 2.45 T / cm2.

For a simple farm 6x8 m, the calculated data are: the step between the supporting poles 3 m, the number of poles - 8, the height of the truss under the rafter-beam system of 0.6 m. Consequently, 12 profile pipes with a cross-section of 40x40x0.2 cm with fixing in nodes.

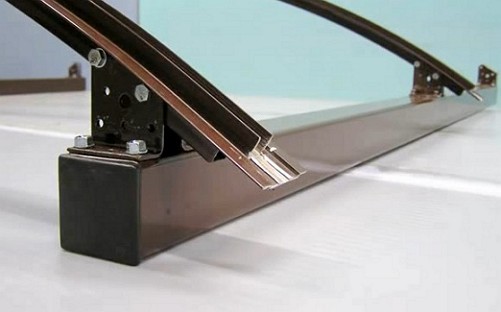

In addition, it is necessary to select consumables, a tool for a canopy, fixing profiles for racks, end and docking profiles for polycarbonate.

How to make a canopy of polycarbonate, step by step instruction

The technology of creating a canopy consists of the stages:

Preparing the site for the installation of vertical racks.

Step 1. We drill holes for the installation of racks to a depth of 60 cm.

Mounting of vertical racks according to the dimensions of the drawing.

Step 2. We place vertical racks from the profile pipe of a certain ø into the drilled hole and pour the installation with a mixture of sand and rubble.

Step 3. Concrete the hole, check the verticality of the pillars and withstand the time of the full cycle of concreting.

Mounting of mounting beams and knots on the wall of the house

Step 4. Mark the place of installation of transverse beams on the surface of the wall or roof and drill holes for fasteners.

Step 5. Install the transverse mounting beams at the desired height.

Cross arch stands are fixed to one support post, bent to the required radius and fixed on the opposite side.

Installation and fixing of trusses or beams in support units.

Step 6. We install finished roofing trusses with the subsequent fastening in support units with the help of bolted connections.

Cutting polycarbonate sheets with subsequent installation.

Step 7. Prepare and cut sheets or panels of polycarbonate in the size of the canopy.

Step 8. Isolate the ends of the sheets.

Fastening sheets in place with special fasteners.

Step 9. We lift and place polycarbonate in place with the orientation of the sheet and the subsequent fastening.

Step 10. We join the sheets of polycarbonate using docking profiles.

How to install a canopy, shown in the video.

We will not hide, the technology of mounting the canopy, especially from roof arch farms is labor-intensive. Therefore, a healthy alternative is considered to be collapsible cantilever sheds on the cables and trusses, connected by a curved barbell or a farm.