Internal finishing of the pool is the most important stage of the work on the construction of the pool basin of reinforced concrete. Traditionally, it is customary to decorate such structures with ceramic mosaics or tiles, as these materials have an attractive appearance and serve for quite a long time. But the decoration of the pool basin with pottery is a painstaking and long work, and the cost of the materials themselves is by no means small. Building technologies are developing rapidly, and today a lot of pool owners prefer polyvinyl chloride film as a finishing material. This coating has a lot of advantages: it is mounted very quickly, literally in a few hours, the cost of the material is at least 3 times lower compared to ceramics, and the film pool looks no worse than a ceramic mosaic.

Content

- 1 Finishing and waterproofing of the pool basin with PVC foil

- 2 PVC film: choose according to taste and financial possibilities

- 3 Advantages of PVC film

- 4 Disadvantages of PVC film

- 5 Swimming pool with own hands, step by step description of works

- 6 Decoration of the pool basin with polyvinyl chloride film

Finishing and waterproofing of the pool basin with PVC foil

The advantage of modern PVC film is not only in attractive appearance and low cost. It is also a wonderful waterproofing material. The film is absolutely hermetic, which allows you to save considerably on waterproofing the pool bowl. And if even in the concrete base of the bowl there are cracks or any damages, the film will reliably hold water in the container. Therefore, PVC film is often used in the reconstruction of the already used pools. If the bowl was somehow damaged and began to flow through the water, it can simply be covered with a film coating, even over the original finish. In this case, it is necessary to ensure good adhesion of the film to the surface in order to prevent its detachment.

PVC film: choose according to taste and financial possibilities

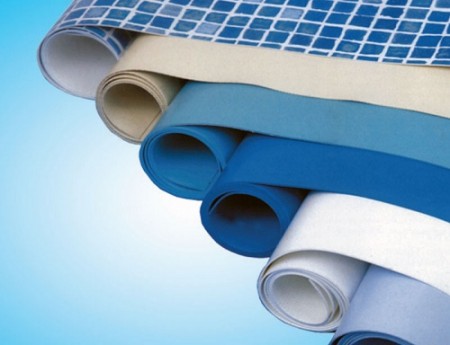

Depending on personal preferences and the availability of funds that the buyer is willing to spend on finishing, you can choose one of three types of finishing film available for sale:

- Plain, non-reinforced PVC film. The most budgetary and simple option. The material has a thickness of 0.65 to 0.85 mm. It is characterized by low strength and reliability, therefore it is most often used for the finishing of demountable pools.

- Reinforced PVC film. A fairly popular film coating for the pool, has a thickness of 1.5 mm. For additional strength, the film is reinforced with a polyester thread. This type of coating is characterized by good resistance to mechanical damage, ability to maintain shape and not stretch. Due to the fact that the reinforced film is very strong, it can be safely used for finishing reinforced concrete basin bowls, where the walls are exposed to rather high loads due to high water pressure.

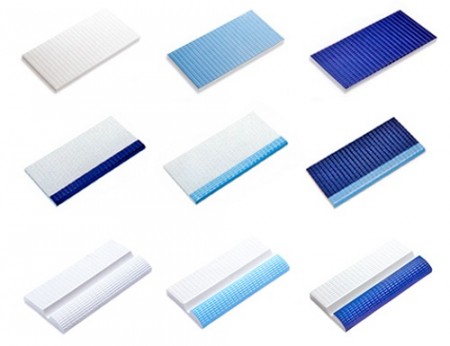

- Anti-slip PVC film. Has a ribbed surface that prevents slipping. This film is most often bought for the finishing of family pools, where children will bathe.

- PVC film with acrylic coating. This material has a bactericidal coating of acrylic, which prevents the growth of bacteria and algae in microscopic pores of the finishing material. Such a film retains color, elasticity and other characteristics twice as long as the above-mentioned analogues. There are also varnished membranes on sale. This material is acrylic in a mixture with PVC. At first glance, such a membrane is difficult to distinguish from a pure acrylic surface, but the bactericidal and performance properties of the membrane are somewhat worse.

Advantages of PVC film

As we have already mentioned, the main advantage of PVC film, or, as it is also called, liner, is that it simultaneously plays the role of decorative coating and waterproofing of the basin basin made of concrete. In addition, this finishing material is hygienic, resistant to UV rays, and transmit temperatures. The film perfectly tolerates the corrosive effects of chemical pool care products recommended for PVC coatings.

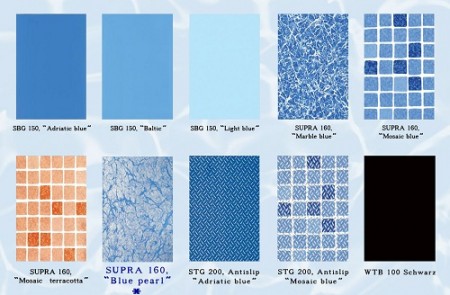

The color scale of this finishing material is presented quite widely. The buyer can choose the coloring accordingly with his ideas about the "sea depths". The film is produced in different shades of green, blue and blue colors. This material very beautifully colors and highlights the water in the pool, giving it a resemblance to the real sea. On sale there is also a film that simulates a mosaic coating of various tones and colors.

Its high popularity film is also due to a very fast installation - it is possible to trim the entire inner surface of the pool basin in a very short time. And, of course, not the least role is played by the democratic price of PVC materials, as well as the low cost of works on their installation.

Disadvantages of PVC film

Unfortunately, this practical and inexpensive finishing material is not without flaws. Over time, the surface of the film inevitably becomes covered with numerous scratches, which in time will lead to the rupture of the material. It will happen, of course, in 6-7 years, but the finish will have to be changed completely. Someone may not like the butt seams on the surface of the film. They can only be viewed near, and they do not rush into the eyes, but they somewhat spoil the appearance of the finish. PVC film can not be used for finishing, if there are groundwater near the surface.

Swimming pool with own hands, step by step description of works

- First, you need to choose a suitable location for the future pool. It should be fairly even, dry, free from trees and bushes. The size of the platform should be greater than the future bowl by about two meters.

- After that, the marking is made, the size and shape of the container are determined.

- Digging the foundation pit under the pool basin. Calculation of the pool bowl should be the following: the excavation should be digged with a margin exceeding the future basin by about half a meter in depth and width. Depth can be chosen any, but the best option is a smooth drop from 1 to 1.6-1.8 meters. In such a pool will be comfortable both for children and adults.

- After the foundation pit is ready, and the dimensions of the future bowl are known, a consultation of the pool specialist is required, as well as the layout of the communication.

- For a pool with a film coating, a concrete bowl is the best choice. Casting a bowl of concrete is made after the pre-installed and unfastened formwork. As an option - a concrete bottom and brick walls, which can then be plastered. But it is best to make a monolithic reinforced concrete bowl - this is reliable, and the surface will be smooth enough and smooth for the installation of PVC film.

- After the bowl has dried, the casing is carefully dismantled, the concrete is allowed to settle for about a week, after which it is possible to start the surface finishing with PVC film.

Decoration of the pool basin with polyvinyl chloride film

The laying of films is most often handled by special teams that work for the vendor of materials. At the same time, special equipment and materials are used. Although sometimes the owners of the pool in order to save their own pool. This requires special knowledge, skills, and tools, as well as the availability of detailed instructions. Below we will consider step by step all the work on finishing the PVC basin with a film.

- To begin with, it is necessary to remove absolutely all garbage from the basin basin, to clean the surface of the concrete. If the pouring is uneven, it will be necessary to plaster the concrete. This is necessary in order that the film is not deformed due to unevenness of the concrete surface.

- After the bowl for the pool is fully prepared, you need to lay a special heater. Its function is not to allow the water to cool too quickly, and to reduce the friction of the film against rough concrete, thus prolonging its service life. When the pool is inside, geotextiles are used as the lining. The heater is fixed to the walls of the bowl with a metal profile with plastic spraying using self-tapping screws.

- The film web is cut according to the shape of the pool, after which the seams are welded using a special tool. After welding, the seams for additional protection are treated with a sealant.

- Using a mounting profile in the form of a corner or a PVC strip, the film is attached to the sides of the pool. The film must also be fixed in places where there are sharp changes in depth or steps, ledges, etc.

- After the film is fixed, the pool is filled with water. At the same time, about 30 centimeters of water are first collected, then the vertical layers of the material are stretched, and only then the container is filled to the required level.

- Once the water has filled the bowl, the film is welded to the sides, and the pool pool is ready.

As you can see, in the finishing of the capacity of the PVC basin with the film, nothing particularly complicated exists. And if you have the necessary equipment and can work carefully and carefully, in a few hours you can completely transform the gloomy gray concrete surface, and completely transform your pool, which will play with fresh colors.