Practically everywhere in the construction of brickwork, it is necessary to solve the problem of "mating". In any case, the correct joining of walls, intersections and masonry angles should occur clearly and dynamically, as on a spaceship. How to mason brick yourself?

Content

Types of constructions of brick masonry

Structures brick (masonry) are built of stones or bricks by hand, while using a certain technique of laying.

There are certain types of masonry that depend on the material used. These are the types of masonry:

• brick

• small-block

• Large block

• rubble

• Benches.

Brick masonry is made of ceramic, less often lime-bricks. Small-block and large-block masonry - from blocks of various materials (cement and ceramic stones). Butovaja a laying is erected with application of stones of the wrong geometrical form, in structure of which cement and but. The casing is characterized by the presence of treated stones, having a geometric shape.

The versatility of brickwork makes it possible to produce subsequent facing with decorative materials. Figures and photos of bricklaying can be found in public building codes and regulations or other regulatory documents.

Golden rules of brickwork

When working on the erection of brickwork, it is necessary to adhere to certain rules that guarantee high-quality work performance and structural stability.

In contrast to the first and second "rules of the drill", the process of erecting brick walls has three basic rules. We recall that these rules of masonry read:

The first rule

Plane 1 order should be perpendicular and horizontal to the action of the resulting compression force. Also these planes should be parallel to each other.

The second rule

Plane 2 and 3 order should also be perpendicular to plane 1, and perpendicular to each other.

Third rule

The load distributed from a single brick must fall on two lower bricks.

Execution of the "golden rules" will ensure proper work of the brickwork solely on compression, excluding the load on the bend.

Types of brick masonry

There are the following types of masonry:

• solid

• lightweight

• reinforced

• decorative.

Brick masonry solid is made by a monolithic construction with a characteristic width of half a brick. The orientation of the bricks in the continuous masonry has a longitudinal direction with respect to the outer plane of the wall.

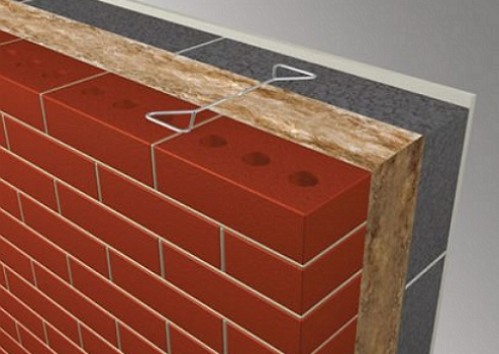

Lightweight masonry is widely used in the construction of walls of houses of low storeys. Masonry lightweight consists of two walls, half a brick in width, located in parallel. The partition between the whole bricks is filled with heat-insulating materials. However, it is not recommended to perform a full wall for this type.

For structures that can experience heavy loads, reinforced masonry is used. Strengthening reinforcement is placed in horizontal or vertical seams. Reinforcement transverse is performed using metal nets with stacking through 3 rows of masonry.

The most demanded for facing is decorative masonry. Decorative masonry allows you to combine ceramic and silicate bricks when facing facades, columns, walls and arches.

Masonry technology

The technology of masonry construction implies compliance with the technological requirements regulated by the building codes, namely:

• Brick masonry should be dressed

• fundamentally strict vertical and horizontal lines

• smooth, eliminating any deformation, the front surface.

Before the beginning of the erection of brickwork with their own hands, it is necessary to prepare and clean the base, marking the outlines of the corners being built along the perimeter according to the working draft. The contours of the bearing walls and partitions are marked using a cord. Then the base is moistened. Such measures are necessary to ensure that the substrate does not "pull" moisture from the solution, which will be installed brick.

The beginning of the brickwork can have a count from the corner of the walls. The initial application of the solution is carried out along the guides and the outermost bricks. After this, the cord is laid on both sides of the future masonry, and the cord must not sag or be moved.

masonry start

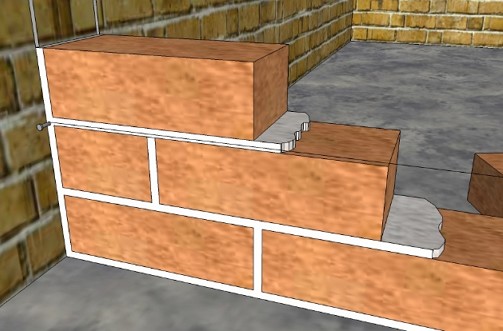

After the construction of the basement or the basement of the building, work on laying can begin. It is recommended to waterproof the cap. The protruding base of the building is protected with a decorative galvanized plum.

The erection of brickwork begins with the layout of bricks. How to produce a brick layout, shown in the video.

)

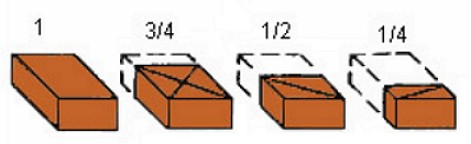

Depending on the type of masonry to be erected, it is recommended that the brick be laid in such a way as to overlap the seams of the lower row. Observance of the horizontal and vertical walls is carried out using the construction level and plumb. For the correct ligation of the brick, you can use the brick parts: halves, (¾) bricks.

dressing

When building a brickwork, the principle of dressing is used. The principle of dressing is that the top laid brick must necessarily rest on the two lower bricks. And the minimum depth of laying is a quarter of the brick. Thus, the uniform distribution of the load on the seam is carried out over the entire area of the masonry, including the width of the wall.

There are following conventional systems of dressing:

• single row

• three-row

• multi-row.

Using the system of dressing, monolithic and structural strength will be achieved. There are dressings of sutures: vertical, longitudinal and transverse. By the way, about the seams of brickwork.

masonry seams

The thickness of the applied solution, smoothed over the surface, is from 1.6 to 1.8 cm. Such a size of the applied solution with shrinkage of the laid brick will create a seam up to 1.2 cm. Therefore, it is recommended to apply the solution at a small distance to the edge.

This average value is 2-3 cm. The mortar solution accounts for about 20 percent of the total masonry volume. Calculation of the total number of bricks with allowance for mortar joints is performed on the PC using a special program that will give the result with reliable accuracy.

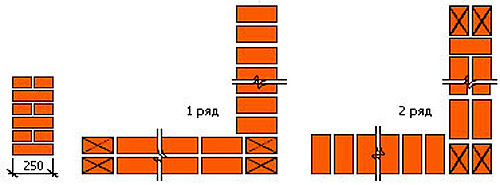

Masonry of corners

The brickwork of the corners can also be made with their own hands. It is the corners that are the basis for the erection of walls and brickwork.

At the beginning of the work on the erection of the masonry in the corners set the order. Laying corners ahead of the main masonry in 3 rows. The thickness and width of the angular masonry can be different. But in any case it is necessary to observe a strict scheme of dressing for corners. There are certain schemes of dressing for the erection of the corners of walls in 1.5 and 2 bricks.

The most common can be called the laying of corners in one brick.

)